Navigation

Applications guide

Probe module selection

To obtain the best possible performance from your TP20 probe, it is important to select the correct probe module for your specific application. When choosing the probe module to be used, the following considerations should be addressed:

- The mass of the stylus assembly and its centre of gravity - it is always best to use the shortest stylus possible

- The orientation of the probe body

- The levels of acceleration and vibration to which the TP20 probe will be subjected - these will vary with each type of CMM and movement velocity

The following probe modules are available for use with the TP20 probe. Each probe module is clearly marked on its front ring and also carries a colour-coded front cap as follows:

- Low force probe module (green cap)

- Standard force probe module (black cap)

- Medium force probe module (grey cap)

- Extended force probe module (brown cap)

- 6-way probe module (blue cap)

- EM1 STD probe module (black cap)

- EM2 STD probe module (black cap)

Low force probe module

The low force probe module, identified by a green cap, is suited to applications that require a low trigger force, for example rubber seals.

Standard force probe module

The standard force probe modules (SF, EM1 STD and EM2 STD) are identified by black caps and are suited to the majority of applications.

Medium force probe module

The medium force probe module, identified by a grey cap, is provided for use where a higher trigger force than standard is required.

Extended force probe module

The extended force probe module is identified by a brown cap. Typically, this probe module will only be required with large stylus assemblies, and where spurious triggers caused by machine vibration and acceleration preclude the use of either the standard or medium force probe modules.

6-way probe module

The 6-way probe module is identified by a blue cap. This probe module is designed for 6-way operation where there is a requirement to measure in the –Z direction, for example when measuring undercuts.

Stylus selection

NOTE: Choosing the best stylus for a given application is an important factor in achieving optimum probe performance. For further information on the full range of Renishaw styli, please refer to Renishaw's styli and accessories brochure (H 1000-3200) which can be ordered from your supplier or downloaded from Renishaw's web site, www.renishaw.com.

When selecting a stylus, it is important that the stylus length is kept to the minimum required to access all features to be measured, and that the stylus type offers the maximum possible stiffness. Factors that affect stiffness are:

- Joints in the styli that tend to reduce rigidity and should therefore be kept to the absolute minimum

- Stem diameters that are governed by the ball tip diameter of the stylus

- Stem material that can be stainless steel, ceramic or graphite fibre (GF)

It is also important to ensure that the stylus ball diameter chosen is as large as is practical. This not only ensures that the stylus will be as stiff as possible, but also reduces the stylus's susceptibility to surface form and surface finish.

Owing to the modular construction of the TP20, when selecting and using styli the following criteria should be applied:

- Work only within the recommended stylus limits for each probe module (refer to Recommended stylus limits)

- Always use the shortest possible stylus

- If using larger styli than those recommended for use with each probe module, always conduct trials to establish the effect on measuring performance

- Minimise the mass of styli by using either ceramic or graphite fibre (GF) stems

Recommended stylus limits

Owing to the modular construction of the TP20 probe, it is recommended that the limits shown in the figures below are applied when selecting styli to be used.

Low force probe module

The low force probe module has the following recommended stylus limits:- Steel and carbide styli up to 30 mm long

- No star or cranked styli

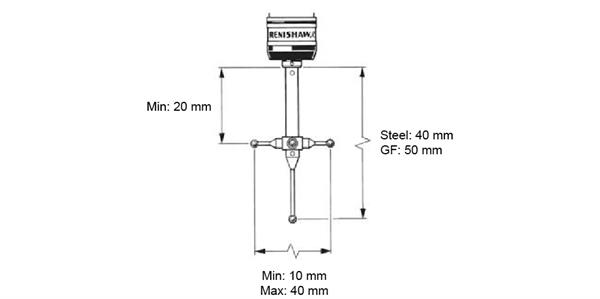

Standard force probe module

The standard force probe modules (SF, EM1 STD and EM2 STD) can be used with the following range of styli:- Steel and carbide styli up to 40 mm long

- Renishaw graphite fibre (GF) type styli up to 50 mm long

- Star and cranked styli up to 20 mm offset

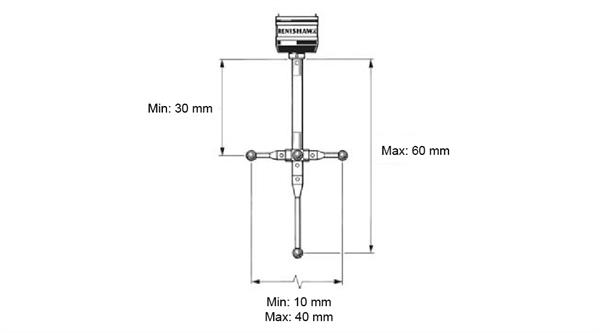

Medium force and extended force probe modules

The medium force and extended force probe modules have the following recommended stylus limits:- Any stylus type up to 60 mm long

- Star and cranked styli up to 20 mm offset

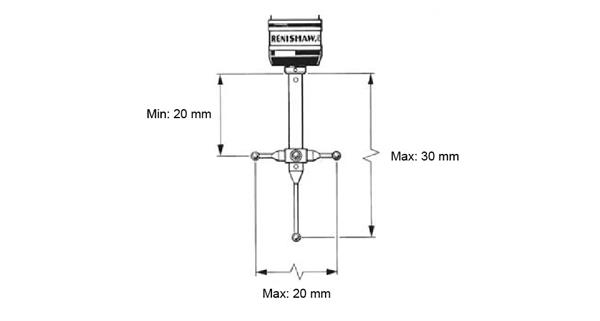

6-way probe module

The recommended stylus limits for the 6-way probe module are:- Any stylus type up to 30 mm long

- Star and cranked styli up to 10 mm offset

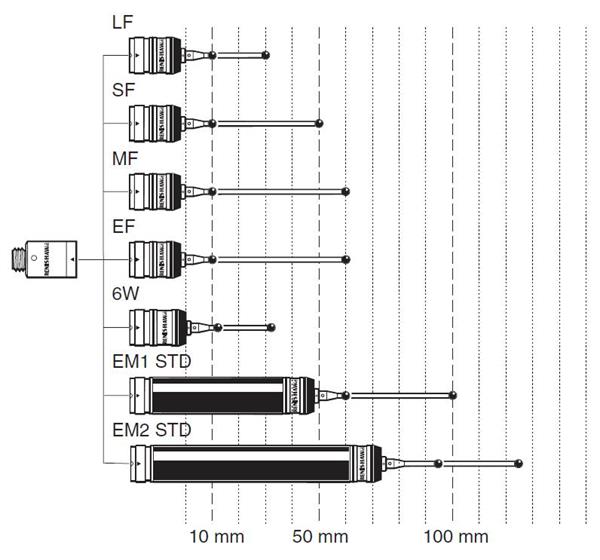

Comparative stylus lengths

A comparison of the minimum and maximum stylus lengths for use with each probe module is shown in the following figure: