Navigation

Cleaning the RVP system

CAUTION: Always adhere to the safety instructions given on the general safety recommendations and instructions in this document. Failure to do so could lead to personal injury.

Following the simple procedures given below will prolong the operational life and maintain the high performance of the system. The user should determine the frequency of inspection and maintenance actions according to the conditions of use.

Kinematic couplings

The kinematic coupling mechanisms incorporated throughout the system have precision ball seating and permanent magnets. It is recommended that all these features be cleaned before first use, and thereafter at regular intervals.

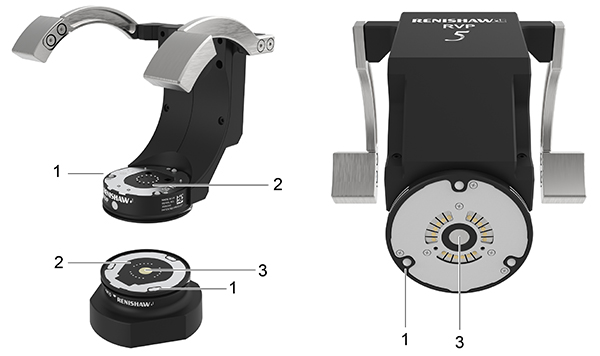

A cleaning kit for the precision ball seating and permanent magnet is available from your Renishaw supplier (part number A-1085-0016). It comprises strips of yellow tack material. Use the yellow tack to clean the areas indicated with arrows numbered [1] on the image below.

With clean hands, tear off a small piece, shape into a small ball and press into / onto each of the features in turn, rotating to a fresh piece of material as you work around.

CAUTION: Ensure no yellow tack debris is left on the surface. The yellow tack should not be used for the electrical contacts [2] or the optical windows [3].

Electrical contacts

The electrical contacts, indicated with arrows numbered [2] in the image below, should be carefully cleaned with an alcohol-based cleaner (e.g. IPA) and a lint-free bud. The frequency of cleaning depends on the local environmental conditions, but should be at least every five hundred changes.

Optical windows

The RVP probe and module optical windows should be cleaned using an optical lens cleaning kit to blow or brush debris away from the window. If debris is still visible, then the optical window should be carefully wiped with a lint free bud and high-purity isopropyl alcohol (IPA). Extreme care must be taken to avoid damaging the optical coating or scratching the glass. Latex gloves should be worn during the cleaning procedure and no attempt to directly touch the optical windows should be made.

ACM

ACM uses a first-surface mirror - the reflective coating is on the front surface of the glass, and is very delicate. Care must be taken to avoid touching the mirror surface to prevent contamination and damage. If cleaning is required, extreme care must be taken to prevent damage to the coating. Latex gloves should be worn during the cleaning procedure and no attempt to directly touch the mirror should be made.

Dust should be carefully removed from the mirror using a can of inert air (air duster) or blower bulb. To avoid depositing saliva on the surface, do not blow on the mirror. When using an air duster, try to avoid depositing the propellant on the mirror. Do not shake the can before use. Start the flow away from the mirror before carefully passing it over the surface at a grazing angle. Hold the can at least 150 mm (6 in) away from the mirror.

If necessary, the surface can be cleaned with optical grade solvents such as acetone or isopropyl alcohol and a clean wipe. Wipes must be soft and well wetted, do not use a dry wipe. Pure cotton wipes or balls, lens tissues and cotton tipped applicators are acceptable. Wipe the mirror surface softly and slowly, in short strokes.

Always use the supplied cover to protect the mirror from contamination when the ACM is not in use.