Navigation

Illumination options

RVP lighting techniques

The RVP system has a number of illumination options to ensure that features can be correctly lit allowing accurate and consistent measurement. Both vision modules have integrated LED illumination to illuminate features that require inspection. The RVP system also uses a technique which uses back lighting to ensure good contrast of material edges or features.

The lighting technique chosen depends on the type of feature and the material of the part being inspected. RVP system image settings can be fully customised and adjusted to provide optimum contrast to inspect a range of features.

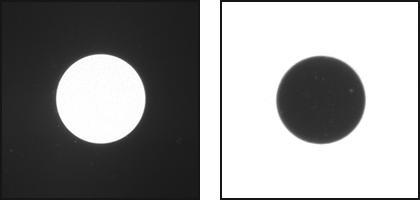

It is important that the correct exposure is achieved for both front and back lighting applications. The image on the left shows a correctly exposed back lit hole. The back edge of the hole is sharp and there is good contrast between the material and the white back lit panel.

The image on the right shows a correctly exposed front lit feature. The front edge of the hole is sharp and there is good contrast between the dark material in the hole and the bright, front lit hole area. When using front lighting, more RVP image settings may need to be adjusted to get the optimum contrast and to reduce unwanted reflections.

Ambient lighting

Ambient light is an important variable when using the RVP system. For accurate and repeatable inspection, the ambient environment lighting should be as consistent as possible. Any changes in ambient lighting can potentially affect the system's performance.