Navigation

UCC T5 introduction

The UCC T5 is the latest generation Renishaw CMM controller product. It replaces the UCC2 and 5-axis card in PH20 applications.

Key | Description |

|---|---|

1 | Machine motors |

2 | Machine scales and readheads |

3 | Probe head - PH20 connects to UCC T5 via the orange machine cabling |

4 | UCCassist-2 commissioning software and application software |

5 | UCC T5 and power amplifier SPA3-2 - these connect to the machine cabling |

6 | MCU joystick - MCUlite-2, MCU5-2 or MCU W-2 - connects to SPA3-2 |

7 | PC - connects to UCC T5 via an ethernet cable |

The UCC T5 comprises of a controller in a 19 inch rack-mountable enclosure. It is coupled to the CMM host computer by an ethernet link and to the CMM via external cable interface connectors.

The UCC T5 controller has the capability to:

- control three axes of a CMM (accepting digital readhead signals and generating three axes drive motor control signals) via the SPA3-2 or the UCC AI / UCC BI / UCC PI 80

- accept input signals from emergency stop, air pressure, crash detector, digital SPA, amplifier faults and all axis inner and outer travel limit switches

- accept two uncommitted general purpose input signals and generate one uncommitted general purpose output signal

- interface PH20

- directly support the Renishaw SPA3-2 servo power amplifier

- directly support the Renishaw TEC (16 channels) and RS232 (Mitutoyo) TEC systems

- provide a +24 V supply for use by the CMM switches

The UCC T5 supports the MCUlite-2, MCU5-2 and MCU W-2 joysticks through the SPA3-2.

This guide gives information on physical installation, system connections and communications, as well as assistance in fault finding during the installation of the UCC T5.

WARNING: UCC T5 is not compatible with PH9, PHS, PH10 and REVO systems. No attempt should be made to connect these system components to the UCC T5 as this will result in damage to the product or attached equipment.

The UCC T5 must be used in conjunction with a Renishaw SPA3-2. Setup and commissioning should be completed through Renishaw's UCCassist-2 software.

The UCC T5 has replaced the UCC2-2 and 5-axis daughtercard. It also replaces the TEC card and provides support for 16 channels of temperature compensation.

The UCC T5 uses an external power supply and manages full control of the PH20 head, CMM and probe signals and communicates with the CMM's computer.

Front panel

UCC T5

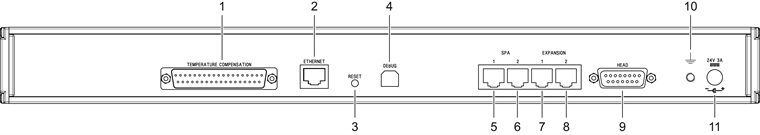

Rear panel layout

| Key | Description | Key | Description |

|---|---|---|---|

1 | 37-way D-type plug for temperature compensation | 7 | Reserved |

2 | Ethernet communications connector to CMM computer | 8 | Reserved |

3 | Reset button | 9 | 15-way D-type socket for PH20 connection |

4 | Reserved - (USB type B socket) | 10 | Equipment bond point |

5 | RJ45 connector to SPA3-2 | 11 | DC power jack |

6 | RJ45 connector to second SPA3-2 |