Navigation

UCC PI 80 maintenance

NOTE: There are no user serviceable parts inside this unit.

Periodically check that all mounting screws and electrical connectors are securely tightened. Electrical safety checks should include inspecting the mains cable for damage and the safety of the connections. Periodical safety checks should also include the function of the emergency stop system, including operation of all switches integrated into the system. After operating the emergency stop system, the servo amplifier system should be checked to ensure servo power can be engaged.

Remove dust from the external surfaces with a clean dry cloth as the unit is not sealed against liquid ingress.

WARNING: Maintenance should only be carried out after the machine has been isolated from the electrical supply, compressed air supply or other energy sources in accordance with the machine manufacturer's instructions.

Filter replacement

The UCC PI 80 has a positive air flow within its enclosure for cooling purposes. This system has a replaceable filter to protect it from the ingress of dust. The machine operator should check the condition of this filter on a regular basis. It is recommended that this filter is removed and checked / replaced as necessary during the machine installer or retrofitter's regular maintenance routine.

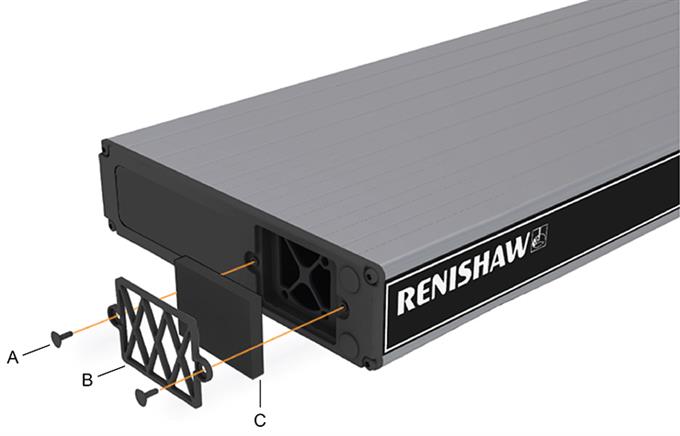

Exchanging / removing the air filter

The following procedure is recommended when exchanging / removing the air filter:

- Remove power from the controller

- Remove the 19 inch rack mounting brackets (if fitted) by removing the two fixing screws

- Pull both the filter retaining clips (1) away from the unit, this should permit the external filter cover (2) to be pulled away

- Remove the filter material (3) from the filter recess (replacement part number of filter is A-5518-0011)

- Replace the filter using the reverse of the method given above