Navigation

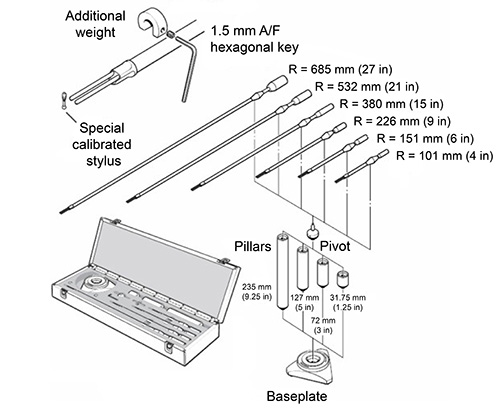

MCG machine checking gauge

Machine checking gauge (MCG) for monitoring the volumetric measuring performance of your CMM.

Special calibrated stylus can be used with TP1, TP2, TP20, TP6, TP6A, MIP* and PH50* with suitable adaptors

Special calibrated stylus can be used with TP1, TP2, TP20, TP6, TP6A, MIP* and PH50* with suitable adaptors- Using the Renishaw MCG, users are able to carry out a 10 - 20 minute interim verification of volumetric accuracy to British standard BS EN ISO 10360-2

- The results give assurance that measurements taken on the CMM are accurate, or give conclusive proof that servicing or re-calibration work is needed

- This process is quick and cost effective and a range of pillar heights and arm lengths mean that volumetric accuracy can be checked on both large and small CMMs

- The probe's stylus slots into the end of what is, in effect, a reference ballbar which travels in a circular path, where radial readings are then taken at 0°, +45° and -45° elevations

- The range of these readings indicate the volumetric measuring performance of the CMM, repetition of a sequence of readings checks the system for repeatablility

- Volumetric measuring perfomance is the maximum error between any two points in a plane, over any distance within the full measuring volume

* Obsolete products

Checking time | |

|---|---|

CNC (DCC) machine | Typically 15 minutes |

Joystick machine | Typically 45 minutes |

Manual machine | Typically 45 minutes |

Measuring range | |

Vertically | ±45° ‡ |

Horizontally | 360° |

Total gauge error | ±0.5 µm (0.00002 in) |

| Kit | Description |

|---|---|

| MCG1 | Small kit - for machines up to 1 m³ (35.315 ft³) |

| MCG2 | Comprehensive kit - for machines greater than 1 m³ (35.315 ft³) |

| Part number | |

|---|---|

| Machine checking gauge kits | |

| MCG1- small CMM checking gauge kit for CMMs up to 1 m³ | A-1007-0006 |

| MCG2 - comprehensive CMM checking gauge kit for all CMMs | A-1007-0056 |

| MCG - 101 mm single arm kit | A-1007-0150 |

| MCG - 151 mm single arm kit | A-1007-0151 |

| MCG - 226 mm single arm kit | A-1007-0152 |

| MCG - 380 mm single arm kit | A-1007-0154 |

| MCG - 523 mm single arm kit | A-1007-0155 |

| MCG - 685 mm single arm kit | A-1007-0156 |

| Machine checking gauge accessories | |

| SA3 - M12 location piece (for mounting gauge to CMM table with M12 thread inserts) | M-5000-4163 |

| M3 20 mm long stylus extension | M-5000-3592 |