KMTC promotes the quality standards of Chinese 5-axis CNC machine tools

Kunming Machine Tool Company Ltd, China, (KMTC) has developed a variety of ‘China's first' high performance machine tools, leading the development of machinery and the machine tool industry in China. As a market leader in metrology, Renishaw has provided KMTC with advanced solutions in machine calibration and performance evaluation, including XL-80 laser interferometer, QC20-W telescoping ballbar system, XR20-W rotary axis calibrator and AxiSet™ Check-Up.

Advanced solutions in machine calibration

KMTC has a very strict quality control where each machine has to be calibrated twice: in manufacture and at the client site before it goes into production. Some large machine tools need to be dismantled after first calibration in manufacture, and calibrated again after re-assembly on site. Mr. Yang, supervisor of KMTC Metrology Centre, says “We used to adopt laser interferometers from another supplier before we started the partnership with Renishaw. Although the other supplier's system performance was good, it was a problem when travelling to customer sites as we had to carry the full system kit in 3 large cases. We found many advantages when we switched to Renishaw's first generation ML10 laser interferometer system which was compact and portable. We now widely use Renishaw's latest XL-80 laser interferometer system in our production and benefit from its extended functionality.” KMTC has purchased 18 laser interferometer systems.

In KMTC's current machine tool models, the accuracy and resolutions are up to 3 µm/m and down to 1 µm/m respectively. KMTC engineers are now able to finish the calibration on an axis of 2 to 3 metres travel distance in 30 minutes.

Axis length can be up to 60 metres on some models. Renishaw's XL-80 laser interferometer offers accuracy of ±0.5 µm/m at normal environmental temperature. It can provide a resolution of 1 nm at a speed of 4 m/s as well as measuring distance up to 80 metres, which is long enough to satisfy most of the machine tools manufactured.

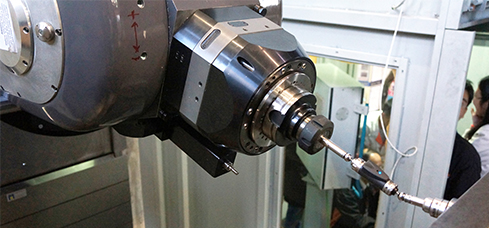

Transforming rotary axis calibration

Rotary axes are becoming more popular in use with the growth in 5-axis machine tools. Conventional rotary axis assessment is not only time consuming but also requires skilled operators. Mr Yang said “We used to adopt a multi-tooth indexing table working with a quasi laser tube or a 24 face prism with auto-collimator to measure positioning accuracy of rotary axes. During the measurement, the upper half of the multi-tooth indexing table is lifted off manually and turned to a defined measuring angle. Then, we counter rotate the rotary table by the same angle to re-align with the laser tube. As a result, the errors can be measured. The accuracy of this approach is quite high, up to ±0.2 arc seconds but the tradeoff is time consumed; even an experienced technician has to spend one day to complete the measurement. The 24 face prism projects images on its reflective surface via the light tube. However the limitation is the measuring angle interval must be a multiple of 15 degrees.

The Renishaw XR20-W rotary axis calibrator has transformed the way we calibrate rotary axes on machine tools. The XR20-W works with the XL-80 laser, allowing the measurement to be completed within 2 hours, reducing labour costs. The operation is quite simple, available with a software user interface in Chinese language, where operators with basic computer knowledge are able to get started quickly."

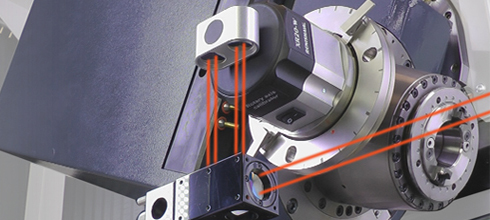

The Renishaw XR20-W rotary axis calibrator employs wireless operation where data capture is synchronized to axis movement, with accuracy up to ±1 arc second, allowing automated measurement at any defined angle interval. All calibrators are factory calibrated and delivered with traceable certification. The XR20-W also supports off-axis measurement, allowing measurement even when the calibrator is not directly installed on the rotary axis pivot point. It is one of the frequently used functions by KMTC.

“The XR20-W features many improvements over its RX10 predecessor, including Bluetooth wireless technology which makes the data capture process more reliable. Renishaw has a strong reputation in metrology so some of our customers specifically request that we use Renishaw's calibration products for commissioning, despite us explaining that traditional methods, such as multi-tooth indexing table, are able to offer comparable accuracy too", concluded Mr Yang.

Apart from laser interferometers, KMTC has also started to incorporate use of the Renishaw QC20-W ballbar system into its production. With a simple and quick ballbar test a user can identify the overall performance of their machine tool, as well as diagnosing problems. This enables customers to measure conventional 3-axis machine tools in accordance with ISO 230-4.

Renishaw has launched Ballbar Trace software, which it offers to existing ballbar users for free. This provides verification for 4 and 5-axis machine tools in accordance with ISO 10791-6 using XCal-View data analysis software.

KMTC also uses Renishaw's AxiSet Check-Up to perform a fast and accurate health check of rotary axis pivot points on multi-axis machine tools, and automatically update parameters and compensations for rotary axis pivot point position errors. This has greatly improved the precision performance of 5-axis machine tools.

Kunming Machine Tool Company Ltd (China)

KMTC is capable of developing systems with technology and specification comparable with the top manufacturers in the global machine tool market. Mr. Liang Feng Peng, Vice President of KMTC said "We have produced parts such as bearings and accessories for some German manufacturers. In future, KMTC will continue the development in industries such as wind power, automotive, aerospace and engineering machinery. At the same time, we will allocate more resources in horizontal machining centres. We have recently provided a custom solution of automatic production lines for a well-known automobile parts manufacturer."

Benefiting from Renishaw's technical expertise

Manufacturers encountering technical issues during machine tool measurement need support and guidance to help them achieve optimum measurement results. “KMTC has been collaborating with Renishaw for more than 10 years. Renishaw sales engineers are always very helpful and provide invaluable technical knowledge and support. They always respond to us quickly and provide useful suggestions. They are happy to share information about updates and notify us of new products, which is one of the key reasons why KMTC and Renishaw maintain such a long term partnership." Mr Yang said.

Company background

Kunming Machine Tool Company Ltd (KMTC), a subsidiary of Shenji Group, is a leading machine tool manufacturer in China. Established in 1939, KMTC has successfully developed over 400 products over 70 years, among which was China's first precise horizontal machine centre and high precision jig borer. KMTC is in the ‘Top 100 Chinese Companies of Excellent Quality'. Its product lines cover jig borer, floor boring and milling machines, planer boring and milling machines, horizontal boring and milling machines, gantry boring and milling machines, horizontal machining centres and machine tool accessories.