CARTO add-ons

CARTO add-ons

Licensed options available to buy from our online store

- Off-axis rotary measurement mode

- Pitch and volumetric compensation for a range of machine controllers

Off-axis rotary measurement mode

The off-axis rotary measurement mode in CARTO, provides a single source for testing off-axis measurement using the XR20 rotary axis calibrator with the XL-80 laser system or XM-60 multi-axis calibrator.

Off-axis rotary measurement mode allows the user to:

- automatically calculate the offset distance between the centre of rotation of the XR20 rotary axis calibrator and the centre of rotation of the rotary axis

- generate a test part program (which synchronises rotary axis and linear axis moves to maintain laser beam alignment)

- remove any contributory linear axis angular error from the observed rotary axis results, giving 'clean' results for the rotary axis

Supplied as an activation ID compatible with Windows 10 64-bit (version 1803 or greater).

How to order

Use our Online store to order 24/7. Shop online or by contacting your local sales team.

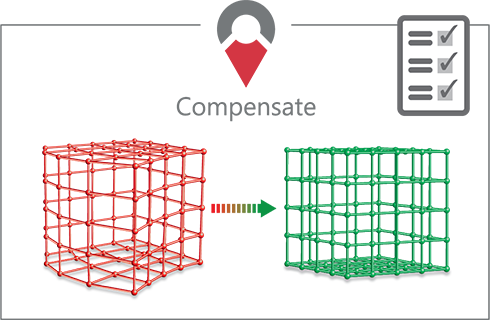

Compensate

Semi-automatic error correction in native machine tool language

Compensate allows you to minimise scrap and save costs through:

- easy geometric error correction,

- improved positioning performance,

- reduced downtime editing compensation tables.

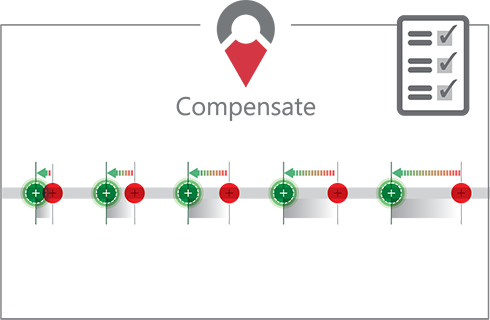

Pitch compensation

Provides easy updates of linear and straightness and rotary compensation tables for controls with supported options.

Compatible hardware

- XL-80 laser interferometer

- XM-60 or XM-600 multi-axis calibrator

Supported machine controllers

- Siemens 840D Solution Line

- Heidenhain TNC 640

- Heidenhain iTNC 530

- Fanuc 30i series

Supplied as an activation ID compatible with Windows 10 64-bit (version 1803 or greater).

Volumetric compensation

Provides easy updates of compensation tables for linear, angular, straightness, roll and squareness (21 degrees of freedom).

Compatible hardware

- XM-60 or XM-600 multi-axis calibrator (linear axis errors)

- QC20 ballbar or XK10 alignment laser (squareness errors between axes)

Supported machine controllers

- Siemens 840D Solution Line (requires Siemens VCS option A3, A5 or A5 plus)

- Mitsubishi M800 Series

Supplied as an activation ID compatible with Windows 10 64-bit (version 1803 or greater).