Primo™ Credit Tokens

Affordable, easy-to-use probing

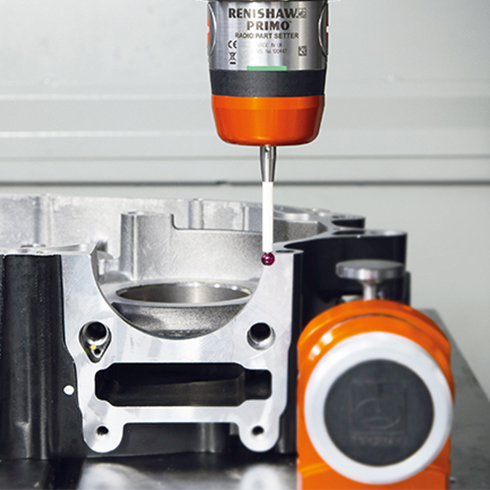

The Primo™ Part Setter and Primo 3D Tool Setter is an affordable range of machine tool probes. Instead of a long-term contract or large upfront investment cost, the probes run using Credit Tokens. A six-month token is included in the purchase price of every Primo system, so that you can experience the benefits of probing before buying more credit.

- If you achieve an increase in productivity, the credit cost is likely to quickly pay for itself.

- If you don't see a benefit from the Primo system, then you don't have to purchase more credit.

- During the six-month period that a Credit Token is active, all the components of the Primo system are covered against accidental damage under Primo Total Protect*

The Primo system can only operate when there is credit available. If your system has stopped working, you may need to renew your Credit Token.

Choose between two available Credit Tokens:

- The six-month Credit Token - enables the Primo system to operate for six months. It provides flexibility in how you pay for credit: if you have a quiet period then you can delay buying a new token until you need your Primo system again.

- The upgrade Credit Token - provides unlimited use of the Primo system in a one-off payment.

Primo Total Protect

Primo Total Protect gives you the confidence to use the Primo system knowing that you are covered against accidental damage. While the 6-month Credit Token is active, all components in the Primo system will be covered against accidental damage. Your Primo probe will be replaced free of charge, giving you worry-free probing*.

Protection is activated when you purchase and register your Primo 6-month Credit Token. It covers your Primo systems (radio part setter, radio 3D tool setter and interface) from the start date of your Credit Token until it expires.

If you are already a Primo system user, you can activate your cover by registering via the link below. Simply enter your system's serial numbers together with your token number. This will cover you for the six-month life of the Credit Token.

*Terms and conditions apply

Downloads

Primo™ Total Protect terms and conditions

- Interpretation

1.1 In relation to the sale of any Key Component, the following terms and conditions replace any warranties relating to defects in or the quality of any Key Components set out in the relevant Standard Conditions. All other conditions in the relevant Standard Conditions shall remain in full force and effect.

1.2 In these terms and conditions, the following expressions have the following meanings:

"Buyer" means the end user buyer of the Key Components.

"Defects Warranty" means the warranty given by Renishaw in paragraph 3.1.1 below against defects in Key Components.

"Key Component(s)" means the key component parts of the Primo System, being the Primo interface and the Primo Radio Part Setter and may (depending on the kit purchased) also include the Primo Radio 3D Tool Setter.

"Primo Credit Token" means the six (6) month credit token issued by Renishaw for use with the Primo System.

"Primo System" means the system marketed by Renishaw as the Primo System, which includes the Primo Interface, the Primo Radio Part Setter and may include the Primo Radio 3D Tool Setter, together with other parts and components (depending on the kit purchased by the Buyer).

"PTP" means Primo Total Protect cover as described in paragraph 3.1.2 below.

"PTP Registration Date" has the meaning given in paragraph 2.1 below.

"Renishaw" means Renishaw plc or a Renishaw plc subsidiary company.

"Standard Conditions" means the standard conditions of sale of the entity that sells the Key Components to the Buyer.

"Upgrade Primo Credit Token" means an upgrade to the Primo Credit Token which unlocks the use of the Primo System such that the length of time the Buyer may use the Primo System becomes unlimited in accordance with paragraph 5 below.

"Upgrade Registration Date" has the meaning given in paragraph 5 below.

2. Registration

2.1 To be entitled to the Defects Warranty and PTP for each Key Component for the period specified in paragraph 3.1 below, the Buyer must register the serial numbers of its Key Components via the registration page on the Renishaw website (www.renishaw.com/primocover) against each Primo Credit Token when the Primo Credit Token is inserted into the Primo Radio Part Setter. The date of registration is the "PTP Registration Date"

2.2 The buyer must register a Primo Credit Token within two (2) years of the date it purchases the Primo Credit Token. If the Buyer fails to register within this timeframe but then subsequently registers (or tries to do so), Renishaw will not provide any PTP for the Primo System against which the Primo Credit Token is (or is attempted to be) registered.

2.3 If the Buyer fails to register any Primo Credit Token against the Key Components, the Defects Warranty and the PTP will not apply. However, the Key Components bought by the buyer will be covered by the relevant Standard Conditions against defects.

3. Defects Warranty and PTP

3.1 Subject to these terms and conditions, Renishaw will, free of charge:

3.1.1 Defects Warranty - make good, by repair or at its option by the supply of a replacement, defects which under proper use appear in the Key Components within the period of six (6) months after the PTP Registration Date which arise solely from faulty materials or workmanship; and

3.1.2 PTP - replace Key Components an unlimited number of times within the period of six (6) months after the PTP Registration Date that are inoperable due to accidental failure or handling during use by the Buyer PROVIDED THAT Renishaw may charge the Buyer for replacement Key Components at the "repair by exchange" rate (quoted by Renishaw from time to time) in the event of the Buyer's wilful removal of any Key Components serial numbers, or intentional or persistent misuse of, or negligence in relation to the Key Components and their replacement (to be determined in Renishaw's sole opinion).

Any repair or replacement shall not benefit from a new period of Defects Warranty or PTP and the original Defects Warranty and PTP period of six (6) months shall remain unaltered from the relevant PTP Registration Date.

3.2 It is possible for the Buyer to register more than one Primo Credit Token at any one time during the same six (6) months Defects Warranty and PTP period against a Primo System, and if the Buyer does so, the Buyer will receive a cumulative number of six (6) monthly periods of Defects Warranty and PTP cover in accordance with paragraph 3.1 above from the first PTP Registration Date.

3.3 In respect of any replacement for Key Components supplied to the Buyer under paragraph 3.1.2 above, Renishaw may also pass on to the Buyer the costs of any local taxes or duties, which it incurs in relation to the replacement.

3.4 The PTP under paragraph 3.1.2 above only covers the Key Components and does not cover any other parts of the Primo System, including but not limited to the LTS ('length tool setter'), the styli or any batteries, which will be covered by the relevant Standard Conditions.

3.5 Any items returned to Renishaw are at Buyer's risk. Repaired or replacement items will be despatched carriage paid by Renishaw to the address requested by the Buyer.

3.6 If Renishaw does not identify a defect in the Key Component, Renishaw may charge Buyer its then current "no fault found" fee.

3.7 Renishaw reserves the right to withdraw the PTP at any time, for any reason, immediately on notice via its website, except that it will always honour the PTP for any Key Components that are registered against a Primo Credit Token as at the date of such notice.

4. Exclusions

4.1 Renishaw is not liable to Buyer for any defect unless Buyer immediately gives Renishaw written notice of the alleged defect with full particulars of the operating conditions under which it became apparent and returns the Key Components or relevant part carriage paid to Renishaw's works.

4.2 The decision of Renishaw on all matters governed by these terms and conditions and in particular (but without limiting the foregoing) as to the nature and cause of any defect or malfunction and how many replacements the Buyer may be permitted by Renishaw under paragraph 3.1.2 shall be conclusive and binding on Buyer.

4.3 RENISHAW IS NOT LIABLE (EXCEPT FOR THOSE LIABILITIES THAT CANNOT BE LIMITED OR EXCLUDED BY LAW), WHETHER IN CONTRACT, TORT OR OTHERWISE, FOR ANY OTHER DAMAGE OR REDUCED PERFORMANCE, DIRECT OR INDIRECT LOSSES BUYER MAY SUFFER ARISING FROM DEFECTS IN, OR ACCIDENTAL FAILURE OR HANDLING OF THE KEY COMPONENTS, OR THE PRIMO SYSTEM.

5. Upgrade Primo Credit Token

5.1 If, at any time an Upgrade Primo Credit Token is purchased by the Buyer, the Buyer must register the serial number (as relevant) for the Key Components when requested to do so (the "Upgrade Registration Date") and in the manner requested by Renishaw against such Primo Credit Token. From the Upgrade Registration Date:

5.1.1 the PTP will no longer apply to the Buyer's use of the Primo System; and

5.1.2 Renishaw will provide a defect warranty for the Key Components in accordance with the relevant standard warranty as set out in Renishaw's standard conditions of sale, for a period which is the longer of:

(a) six (6) months from the Upgrade Registration Date; and

(b) the remainder of the Defect Warranty period for the Primo System set out in paragraph 3.1.1 above (if relevant) PLUS six (6) months from the Upgrade Registration Date, up to a maximum of twelve (12) months from the Upgrade Registration Date.