Case study: Renishaw technology helps Breton calibrate its in-house machinery and control the quality of its output (docx)

檔案大小: 102 kB

語言: English

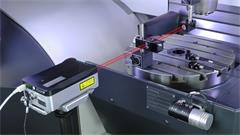

When Breton SpA wanted to add machine tool manufacture to its core business of building stone-processing machinery, the increase in required levels of precision prompted the introduction of around 30 devices from Renishaw, including laser interferometers, rotary axis calibrators, ballbars and touch-trigger probes. As a result, Breton’s range of high-speed, five-axis CNC machining centres are now among the world’s most advanced.

此類檔案需要使用閱讀器,您可在以下網址免費獲得 Microsoft

您是否未找到您要找的內容?

告訴我們您無法找到 我們將盡力提供援助