Manufacturing

Renishaw is committed to delivering exceptional levels of service and product quality to our customers through superior manufacturing.

Video produced for Renishaw and Made Here Now by Layer Creative

Process control

At Renishaw we believe that the key to improving manufacturing processes lies in enhancing process control; Process control enables us to identify and then eliminate or adapt to sources of variation in our manufacturing process. Uncontrolled variation is the enemy of competitiveness and profitability. It causes waste and inefficiency, leads to high quality costs and manning levels, and results in late deliveries and poor traceability.

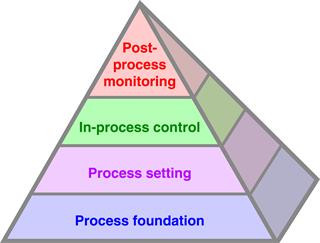

Using our experience in manufacturing we have developed a robust framework for managing process control, the Productive Process Pyramid™.

Demonstrating our confidence in this framework and our own products, we use them both in our own manufacturing processes. Each Renishaw product that is produced is measured and verified by another. This ensures that we maintain the high levels of accuracy and quality that we deliver to our customers.

Manufacturing at Renishaw

Throughout our history our manufacturing operations have supported Renishaw's growth. This has been aided by our sustained long-term commitment to the latest manufacturing technologies and facilities.

We continue to be committed to significant investment in our manufacturing capability. An example of this is our use of the Renishaw Automated Mill Turn Inspection Centre (“RAMTIC”) system. RAMTIC was developed in the early 1990s and uses a standard machine tool platform that has been modified for our needs. This involves a high degree of automation and closed-loop control that is facilitated by Renishaw probing technology for tool setting, in-process monitoring and component validation. RAMTIC continues to be the mainstay of our standard machining platforms with 50 systems now in operation accross the company.

We are also highly committed to investments in assembly-based technologies. Our electronics production facilities utilise the very latest technology capable of placing 40,000 components per hour.

We provide exceptional facilities for our manufacturing operations. We invested in a 460,000 sq ft site near Cardiff, South Wales in 2012 and we are now at 50% occupancy at the site. Refurbishment of the remaining space is currently in progress to provide the necessary space for expansion.

Supply chain management

As a manufacturer operating in a high mix/low volume environment, with a strategy of delivering exceptional customer service, our approach has been to maintain as much control as possible of our supply chains. This has been achieved through a combination of in-house manufacturing, duplication of critical processes, dual sourcing and long-term partnerships with our third party suppliers.

Worldwide facilities

- UK:

- Woodchester 165,000 sq ft

- Stonehouse 100,000 sq ft

- Cardiff 460,000 sq ft

- Smaller operations at our New Mills headquarters in Wotton-under-Edge, Stone and York

- Ireland: Swords 70,000 sq ft

- India: Pune 50,000 sq ft

- Germany: Völklingen 19,000 sq ft

- France: Lyon 5,500 sq ft

People

Consistent with Renishaw's overall philosophies, the manufacturing operations take a long-term view with regard to development of our people. Employee turnover within manufacturing is below 10%, and this stability, coupled with a growing business, provides a platform to develop our people within the organisation.

All manufacturing graduates and apprentices follow a well-defined programme that provides exposure to a wide range of functions and technologies so that we develop well-rounded individuals with a broad grounding in a variety of manufacturing-related disciplines. Many of our apprentices and graduates succeed in developing career paths into more senior engineering and operational roles within the organisation.

In many cases, employees transfer from manufacturing into other parts of the business to assist other functions, such as new product development or applications engineering, making best use of the experience gained within the manufacturing arena.