Modular and custom fixturing for metrology

Renishaw offers a range of modular and custom fixturing for use with CMMs, Equator™ gauges and vision systems. Discover how our fixtures can improve throughput and repeatability.

Your single source for metrology fixturing

Improve your throughput, reproducibility and accuracy of your inspections with quick and repeatable fixturing set-ups.

Your partner in precision for over 50 years

Whether you are inspecting workpieces for aerospace, automotive, electronics, industrial or medical applications, Renishaw fixtures can provide a complete solution. Our extensive range of modular fixturing components is designed to enhance the efficiency and throughput of your inspection process.

Metrology fixtures for CMMs and Equator™ gauging can improve throughput, reproducibility and accuracy of your inspection process. Our modular range provides quick and repeatable fixturing set-ups for your components. Discover how we can help minimise your set-up time.

Renishaw's vision fixtures and acrylic base plates allow for back lighting and a clear, clean look at the part from your vision system and multi-sensor machines.

Find out more about our comprehensive range of vision fixturing and how we can assist you.

Compatible with any portable CMM, white light or laser system, our metrology tables give you the freedom to move about your workspace or metrology inspection area with ease. Discover how our tables are designed to suit your needs.

Renishaw's FixtureBuilder software creates fixturing set-ups to provide documentation and assist offline programming for CMM, Equator™ gauging and vision inspection. Explore how our 3D modelling software can benefit you with a free 30 day trial.

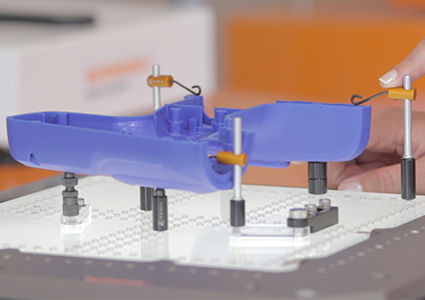

What is modular fixturing?

Modular fixturing is a workpiece holding system that uses a series of components for building specialised workpiece holders. It allows for rapid and economical setup, consisting of tooling plates, clamps and components. Renishaw's wide range of modular fixturing can improve throughput, reproducibility and accuracy of your inspection process with quick and repeatable fixturing set-ups.

How to order

Use our Online store to order 24/7. Shop online or by contacting your local sales team.

Why choose Renishaw metrology fixtures?

We recognise the complexities involved with fixturing for inspection, so we have developed a product line that provides a reliable and repeatable foundation for measurement.

We have considered the different types and modes of inspection, whether it be CMM, vision system, articulating arm, 3D scanner, optical comparator, or other device, our range can be used to improve efficiency and throughput of the inspection process.

Our easy to use modular and custom fixturing is key to reducing time wasted during one-off and repeat workpiece inspection, and this can be further enhanced by using our software, FixtureBuilder, to build a fixture which can be used within native CAD software and to auto-generate a set of work instructions.

- A large range of flexible solutions

Renishaw's broad range of modular fixturing components and custom design capabilities provides solutions for a variety of applications and workpieces of almost any size, shape or material. Base plates and components are available as standard in M4, M6, M8 metric and 1/4-20 imperial thread sizes. - Fast, accurate and repeatable

All components are hand-tightened and require no special tools. Set-ups can be documented and repeated with accuracy using our alpha-numerically labelled base plates. - Unrivalled durability, wear resistance and quality

Our heat treated steel components and hardcoat anodised base plates provide a smooth and scratch resistant finish. - Enhanced productivity during part inspection

Renishaw's FixtureBuilder software helps users create fixturing set-ups, provides documentation and assists with off-line programming.

Frequently asked questions

Why use fixturing in metrology?

Fixturing ensures repeatable and reliable results for workpiece inspection. Renishaw offer easy to use and hardwearing quality made fixtures which ensure these results. This replaces the need for using unreliable and unrepeatable systems like putty, bolts, and step clamps.

How does a base fit to a machine?

Renishaw fixturing offer Quickload solutions for quick changeover of parts, which work through magnets and locating pins. The benefit of these is that part changeover can be completed in seconds, necessary for any modern-day production facility.

How should I decide which products are required for my fixturing setup?

Understand the workpieces critical features and from there consider the weight, shape, size and fixturing needs. A perfect starting place is Renishaw fixturing kits as these include many parts required to fixture a variety of workpieces.

How do I know how to fixture my workpiece?

Renishaw offers various guides on how to fixture correctly. Some fixtures however may required a custom solution, for help with this, please fill out a custom request form.

Not found what you are looking for?

We can provide custom solutions for your fixturing set-up. Find out more by getting in contact below.