CARTO add-ons

Licensed functionality for your CARTO software to enhance your laser calibration products

Browse our licensed options on our store or contact your local sales team

Off-axis rotary measurement mode

The off-axis rotary measurement mode in CARTO, provides a single source for testing off-axis measurement using the XR20 rotary axis calibrator with the XL-80 laser system or XM-60 multi-axis calibrator.

Off-axis rotary measurement mode allows the user to:

- automatically calculate the offset distance between the centre of rotation of the XR20 rotary axis calibrator and the centre of rotation of the rotary axis

- generate a test part program (which synchronises rotary axis and linear axis moves to maintain laser beam alignment)

- remove any contributory linear axis angular error from the observed rotary axis results, giving 'clean' results for the rotary axis

Supplied as an activation ID compatible with Windows 10 or 11 64-bit (version 1803 or greater).

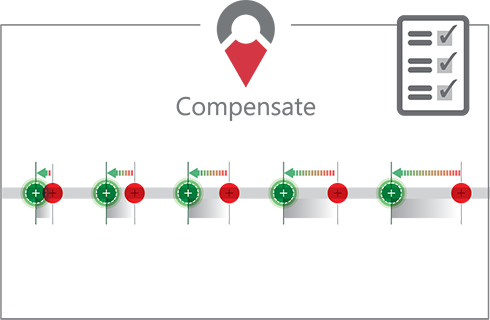

Compensate

Semi-automatic error correction in native machine tool language

Compensate allows you to minimise scrap and save costs through:

- easy geometric error correction,

- improved positioning performance,

- reduced downtime editing compensation tables.

Pitch compensation

Provides easy updates of linear and straightness and rotary compensation tables for controls with supported options.

Compatible hardware

- XL-80 laser interferometer

- XM-60 or XM-600 multi-axis calibrator

Supported machine controllers

- Siemens 840D Solution Line

- Heidenhain TNC 640

- Heidenhain iTNC 530

- Fanuc 30i series

Supplied as an activation ID compatible with Windows 10 or 11 64-bit (version 1803 or greater).

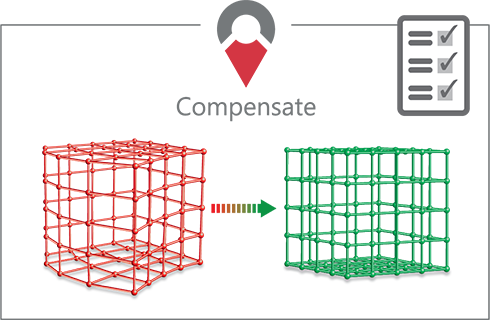

Volumetric compensation

Provides easy updates of compensation tables for linear, angular, straightness, roll and squareness (21 degrees of freedom).

Compatible hardware

- XM-60 or XM-600 multi-axis calibrator (linear axis errors)

- QC20 ballbar, XK20 or XK10 alignment lasers (squareness errors between axes)

Supported machine controllers

- Siemens 840D Solution Line (requires Siemens VCS option A3, A5 or A5 plus)

- Mitsubishi M800 Series

Supplied as an activation ID compatible with Windows 10 or 11 64-bit (version 1803 or greater).

Contact our sales team today

Get in contact with your local office to find out more information and speak to an expert.