Renishaw AM delivers fast parts at Ferrari F1

Reproduced from original article by O. Moda (Tecnologie Meccaniche)

Ferrari is a legend, the most loved Italian brand in the world, and at the heart of this myth, their racing department, have two Renishaw additive manufacturing (AM) machines.

Scuderia Ferrari has never missed a season, and it was the only team for a very long time to produce all the components of its cars, the only team to rouse emotions that go well beyond mere sports. Racing fans appreciate the emotional aspect of races, with cars overtaking at the thrilling speed of 300 km per hour, the skill of the entire team that performs miracles, such as changing 4 tyres in just 2 seconds… then, behind it all, there are many, many other people who work with passion and dedication, who are committed to finding the perfect modification, the ideal improvement that will allow the driver to go that tiny bit faster at each lap, giving him an advantage, however small.

The two machines are located in a dedicated area that is more like a clinic than a typical machine shop because of its white glossy floors.

Why choose Renishaw machines?

The answer is tied to the technological potential, to the awareness of the reliability of all Renishaw products and the ability to listen and to find a solution to all issues that inserting new technology entails. The Scuderia Ferrari team has chosen additive manufacturing machines to make some of its more challenging, metal, engine components.

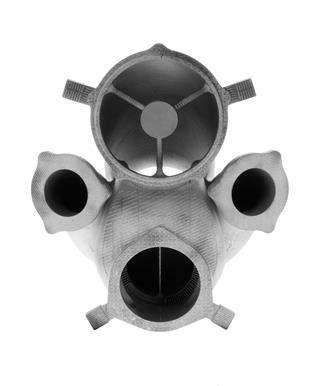

Renishaw additive manufacturing systems use metal powder bed fusion technology to build components directly from CAD files. The parts made at Ferrari have complex geometries and thin-walls and would be very difficult to produce using more traditional methods, such as casting or machining. Unless great care is taken, the quest for extreme light weight could result in weak points and fragility.

In F1, the research is focused on maximum performance with the lowest possible weight. ‘Factors of safety' - normally designed into a part to make it more durable and reliable, add weight which, in a road-going vehicle, wouldn't be an issue.

The goal, therefore, is to design and make a part that does its job reliably for the duration of the race, and preferably not a kilometre more.

The component is one incorporated into every engine. Needless to say, volumes are not as high as if they were production engines, but the part in question is in continuous development.

Sometimes changes to its design are very small; occasionally, the entire part is reconfigured. Whatever the case, the modification needs to be made immediately and a new part produced with minimum delay.

Renishaw AM machines have been built to provide maximum ease-of-use, as well as low material costs per unit. Ninety five percent of unused metal powders are recovered and reused. The machine also offers a small footprint without compromising on the size of parts it can produce.

The Ferrari parts are particularly complex, requiring a manufacturing time of several days. During the process, the operator can add new powder to the machine without interruptions or downtime.

The world of motor racing is quick to adopt tried-and-tested technologies that give them an edge. The team's decision to invest in Renishaw machines was based largely on the latter's ability to provide a solution capable of solving a difficult manufacturing challenge.

Renishaw's engineers worked closely with Ferrari to create the first parts, and to train the Ferrari designers and engineers to get the most from the machines. The machine's versatility was also a deciding factor – it can work with a wide range of metal powders, including steel, titanium, aluminium, and other alloys. It can change between materials simply by changing the operating parameters.

If you would like to republish this article, only text and images used within the article can be published. Any questions can be directed to Renishaw's Additive Manufacturing marketing team, by emailing additive@renishaw.com.