InfiniAM Suite – Renishaw's Additive Manufacturing process monitoring software

InfiniAM suite is Renishaw's AM process monitoring software, which includes two key technologies: InfiniAM Spectral and InfiniAM Camera.

Together, they minimise reliance on post-build analysis, enable early detection of significant build failures and facilitate the investigation of more complex issues and defects.

By identifying and monitoring key variables directly correlated with part properties like density, dimensional accuracy, surface finish, and mechanical properties, InfiniAM enhances quality assurance, efficiency, and productivity.

InfiniAM delivers a deeper understanding of your AM processes when using a RenAM 500 series system, paving the way for consistent, traceable production, and optimised performance.

RenAM 500 series metal additive manufacturing systems

Key Features

InfiniAM provides a better understanding of part quality by using real-time monitoring during manufacturing. It allows engineers to spot issues early and make corrections to ensure the final parts meet quality standards.

With InfiniAM, you gain confidence in your builds through comprehensive data analysis. The software verifies that the correct parameters are being used, reducing uncertainty in the additive manufacturing process.

InfiniAM speeds up process development by streamlining the analysis of build data and allowing for faster adjustments. Engineers can quickly identify effective strategies and optimise settings.

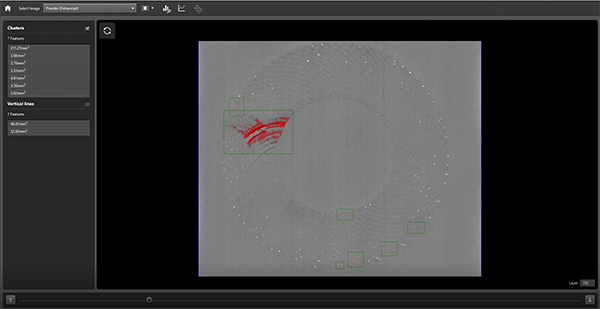

InfiniAM Camera

InfiniAM Camera provides visual process monitoring for additive manufacturing using RenAM 500 series machines. A high-resolution camera captures images of the powder bed after dosing and melting for each layer. The software analyses these images to offer insights into build progression and highlight potential anomalies that may need your attention.

The software can send near real-time alerts when anomalies are detected, enabling quick analysis and response.

Enhance your understanding of the 3D printing process and identify areas for investigation with this powerful tool.

Identified anomaly captured by InfiniAM camera

InfiniAM Spectral

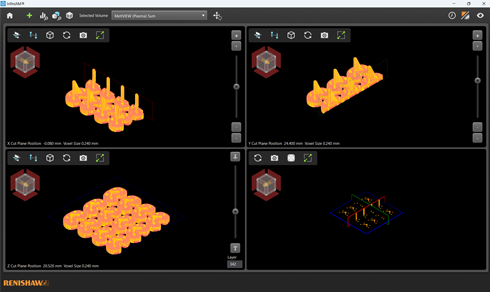

3D heatmap of tibial tray build

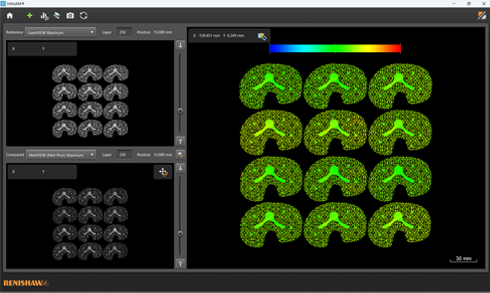

2D heatmap of tibial tray build

These features are visualised as 2D and 3D heat maps of the build, providing insights into the metal properties used in the part. By comparing these heat maps to previous builds, you can gain a better understanding of component quality throughout the manufacturing process.

The software uses Renishaw's LaserVIEW and MeltVIEW hardware, which are sensors that integrate seamlessly into the optical path of the lasers.

MeltVIEW

The MeltVIEW system is an in-line opto-mechanical module. It monitors melt pool emissions across a wide spectral range. The co-axial optical configuration gives a field of view which is determined by the laser scanning system ensuring the melt pool remains in focus of the sensors throughout the build.

LaserVIEW

The LaserVIEW system measures the input of the laser in RenAM systems. The system uses an infra-red photodiode which delivers high-speed performance at the laser wavelength.

Download

-

Brochure: InfiniAM Spectral – Energy input and melt pool emissions monitoring for AM systems

Brochure: InfiniAM Spectral – Energy input and melt pool emissions monitoring for AM systems

InfiniAM Spectral software is designed to operate with Renishaw’s LaserVIEW and MeltVIEW hardware, to provide feedback on energy input and emissions from the AM build process.

[672kB] -

Flyer: InfiniAM Suite

Flyer: InfiniAM Suite

A flyer covering the features and benefits of InfiniAM suite - Renishaw's additive manufacturing process monitoring solution. Includes details on InfiniAM Spectral, InfiniAM Camera and DataHUB.

[2.9MB]

Find out more

To explore licensing options or to learn more about Renishaw's software solutions, fill out the contact us form below.