Industrial applications of Renishaw metal additive manufacturing technology

Create complex metal parts for a wide range of industries.

A wide reaching solution for industry

Metal additive manufacturing allows metal parts to be built without the need for traditional tooling and with few limitations in geometry. Equally, it is complementary to traditional subtractive methods and can be readily integrated into the existing production workspace.

Organisations which use metal parts can make a thorough analysis of current product and production lifecycles to reveal gaps where metal additive manufacturing could prove advantageous - in reducing development time, production steps, costs and use of material.

The early adopters of metal additive manufacturing were high-end technology industries, for example aerospace and motorsport. With increasing application of the technology there is potential for metal additive manufacturing to become mainstream and an integral part of every engineer and designer's toolkit.

Healthcare - dental and medical

Thin wall dental copings are manufactured in production volumes. The highly complex, tailored parts are ideally suited to additive manufacturing – where intricate parts with a low overall volume are competitive when compared with traditional methods.

Early adopters of metal additive manufacturing for medical orthopaedics benefit from manufacturing complex geometries and structures in high grade materials such as titanium.

Automotive

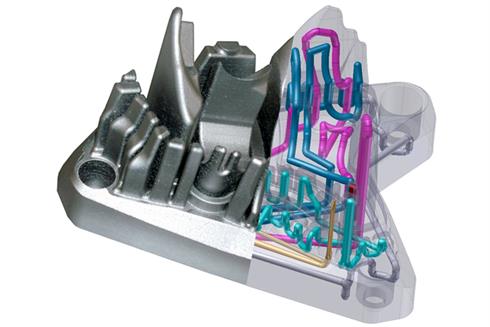

Mould tooling and conformal cooling channels

Metal additive manufacturing can be used to help improve production cycle times and productivity in injection moulding.

Metal mould tools used for injection moulding contain channels to cool the mould. With conventional tool making methods these cooling channels are drilled into the tool in straight lines. Metal additive manufacturing allows cooling channels to be designed and built to contour the mould. This helps to improve cooling performance, extend the life of the mould and reduce waste.

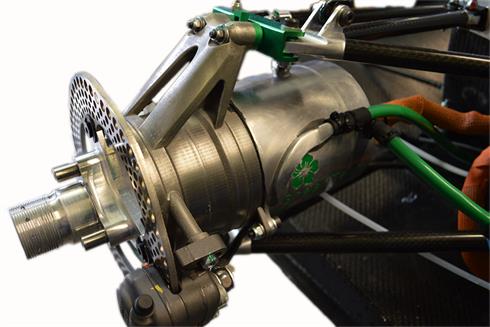

The motor sport industry have adopted metal additive manufacturing for the production of customised parts, for example cooling ducts.

Development contributes to a high proportion of the work in this industry and speed of turnaround of prototyped parts is key to competitive advantage. Functional metal parts can be rapidly produced and performance tested.

Metal 3D printing for automotive

Aerospace

Metal additive manufactured parts are used in the aerospace industry for functional parts including engine turbine blades, fuel systems and guide vanes.

The topological optimisation of parts can improve functionality and reduce weight. Lighter parts can contribute to lighter aircraft and reduce fuel consumption.

Metal 3D printing for aerospace

Creative

A new freedom of design for creative industries including architecture, jewellery and entertainment where highly complex and bespoke items are required.

Living hinges, interlocking parts, thin wall and hollow objects are possible for customised pieces. Metals can be finished using a number of processes for maximum visual effect.

Research

Renishaw partner with a number of universities, researchers and academic institution on metal additive manufacturing projects.

The open parameter ethos for materials used on its systems helps to encourage development of parameters for new materials.