Comparateur double méthode Equator-X™ pour le contrôle en atelier

Comparateur Equator-X™ 500 : deux systèmes en un

Le nouveau système de comparaison à double méthode Equator-X apporte une capacité unique dans l’atelier grâce à sa fonctionnalité de double mode de mesure : absolue et comparative. Les utilisateurs peuvent sélectionner le mode de contrôle optimum en fonction des défis propres à leurs procédés, déployant ainsi deux systèmes en un.

Mode Absolu

En mode Contrôle absolu, le comparateur Equator-X fonctionne comme une MMT de production à grande vitesse et fournit des résultats de contrôle entièrement traçables (ISO 10360-2 = 2,1 μm + L / 300).

La mesure rapide à des vitesses de scan allant jusqu’à 250 mm/s, sans avoir besoin de recourir à des pièces-étalons, s’avère particulièrement utile pour les fabricants qui doivent faire face :

• à une forte variation des pièces

• à des volumes de production faibles à moyens

• à une fréquence de contrôle élevée

Mode Comparatif

En mode Comparatif, le comparateur Equator‑X permet un contrôle ultra-rapide et hautement répétable avec des vitesses de scan allant jusqu’à 500 mm/s et une répétabilité de ±2 μm dans une large gamme de températures. Ceci s’avère particulièrement utile pour la fabrication de pièces en grandes séries, où la cadence est essentielle et où les variations de température ambiante constituent un défi.

Méthode de comparaison

La méthode de comparaison repose sur la comparaison traditionnelle des pièces usinées à une pièce-étalon. Une pièce-étalon est mesurée pour générer un fichier de correction. Chaque série de production est ensuite comparé à l’étalon pour déterminer les cotes réelles de la pièce et voir si elles correspondent aux tolérances définies par l’utilisateur. Dans les usines qui subissent de forts écarts de température, un simple étalonnage suffit pour « remettre le système à zéro » et le préparer à une comparaison à l’étalon, répétable.

Avantages principaux du système de comparaison Equator-X 500

Cadence

Le système Equator-X est capable d’atteindre des vitesses de scan absolu de 250 mm/s et des vitesses de comparaison allant jusqu’à 500 mm/s, bien supérieures à celles des MMT classiques à 3 axes. Grâce à des mesures plus rapides, la capacité de contrôle est augmentée. Ces performances élevées permettent au contrôle de suivre le rythme des opérations d’usinage.

Assurance qualité

Le système Equator-X permet un contrôle entièrement traçable des pièces en cours de fabrication conformément à la norme ISO 10360, garantissant la fiabilité lorsque les mesures sont effectuées hors du laboratoire de mesure et directement en atelier. Le comparateur Equator-X permet une validation continue du procédé de production avec un renvoi de données en temps réel.

Grande souplesse

La possibilité de choisir entre deux méthodes de mesure sur un seul et même appareil permet à l’utilisateur de sélectionner la méthode convenant le mieux à son application. Par exemple, la méthode absolue pour les grandes variétés de pièces ou la méthode de comparaison pour les variations importantes de température ambiante.

Grâce à sa conception compacte et légère, qui ne nécessite pas d’air comprimé, le système est facile à déployer exactement là où cela est nécessaire, en ligne ou hors ligne.

Précision et vitesse redéfinies

La conception du système Equator-X combine déplacements à grande vitesse et précision de mesure sans égale. Grâce à sa conception autour d’une structure en hexapode à rigidité dynamique, les forces d’entraînement inertielles n’agissent qu’en tension ou en compression, ce qui réduit considérablement les erreurs liées à la vitesse observées dans les systèmes MMT classiques à 3 axes.

De plus, les cadres porteurs et de métrologie sont indépendants, ce qui permet d’optimiser le cadre porteur pour les déplacements à grande vitesse sans compromettre les performances métrologiques.

Cadre porteur

La vitesse et les performances remarquables de l’Equator-X sont possibles grâce à six moteurs linéaires disposés selon une configuration en hexapode. Ces moteurs d’entraînement appliquent une force directement sur la plateforme de palpage mobile, évitant ainsi la flexion et la torsion dynamiques présentes sur les MMT classiques.

Les moteurs d’entraînement et les codeurs de renvoi de données de position sont situés au-dessus du volume de travail, à l’écart des principales sources de contamination, ce qui permet de préserver des niveaux de performances élevés, même en atelier.

La structure

La structure est en fibre de carbone, à la fois rigide et légère, est essentielle pour garantir les déplacements à grande vitesse et la précision. Les performances sont encore améliorées grâce à l’application d’une signature de dilatation thermique aux montants en fibre de carbone, qui est utilisée pour construire un modèle global de compensation thermique du système.

Chaque partie liée ayant un impact sur la métrologie intègre le système de codage optique absolu RESOLUTE™, qui permet de déterminer la position absolue immédiatement à la mise sous tension.

Système de palpage

Référence dans le secteur industriel, le palpeur SP25M est un système de scanning polyvalent qui permet aux utilisateurs de scanner la forme, les cotes et la position. Avec le module de scanning SM25-2, le palpeur SP25M offre des performances exceptionnelles sur toute la plage du stylet, de 50 à 105 mm en longueur de travail effective pour les stylets droits et jusqu’à 83 mm pour les stylets coudés.

Le rack à 6 ports fournit avec l’Equator-X permet un changement automatique et répétable entre les différentes configurations de stylets.

Systèmes de comparaison Equator-X™

Les comparateurs Equator-X ont été conçus pour garantir les cadences, l'assurance qualité et la flexibilité en atelier.

Téléchargez la brochure et la fiche technique du produit pour en savoir plus sur la capacité double méthode du système Equator-X.

Toutes les informations en un coup d'œil

Gamme de systèmes de comparaison Equator™ pour la fabrication industrielle

Le comparateur à double méthode Equator-X fait partie de la gamme en pleine expansion de systèmes de comparaison de Renishaw pour la fabrication industrielle.

Puissantes fonctionnalités logicielles – plateforme logicielle MODUS™ IM pour systèmes Equator-X

Le système Equator-X comprend en standard la plateforme logicielle MODUS IM, qui donne aux utilisateurs accès à une suite complète d’applications, toutes conçues pour offrir à la fois clarté, efficacité et facilité d’utilisation, avec une intégration transparente et des fonctionnalités puissantes. Cette solution logicielle puissante offre des performances exceptionnelles et une grande facilité d’utilisation, avec une palette croissante d’outils pour le contrôle par l’opérateur, la création de rapports, la gestion de l’environnement, ainsi que l’analyse et la gestion des machines dans le but d’améliorer la productivité.

Outils de programmation flexibles

MODUS IM offre tout un choix d’applications de programmation adaptées aux différents besoins des utilisateurs, allant d’interfaces intuitives sans code à la programmation DMIS avancée pour les pièces complexes.

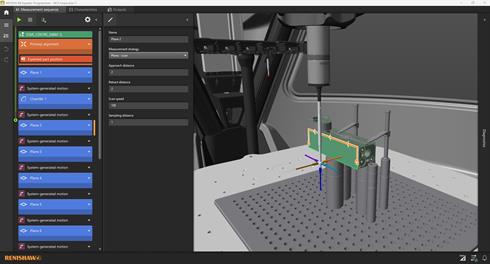

Application MODUS™ IM Equator Programmer

Conçue dans un souci de vitesse et de simplicité, MODUS IM Equator Programmer est une application par CAO basée sur les nœuds qui permet aux utilisateurs sans expérience en codage de créer des programmes de contrôle. S’appuyant sur l’expertise intégrée de Renishaw, les programmes de mesure de plans, de cylindres et de chanfreins sont créés facilement en planifiant automatiquement tous les déplacements du système afin d’éviter toute collision.

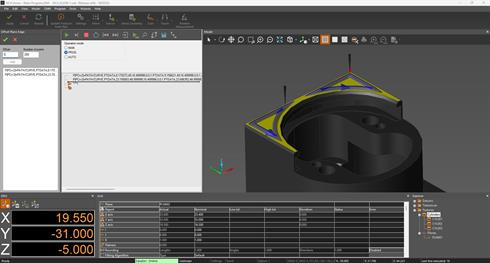

Application MODUS™ IM DMIS Programmer

L’application MODUS IM DMIS Programmer offre des fonctionnalités complètes de programmation basées sur le code MODUS DMIS. Optimisée pour les géométries complexes et les sous-programmes de contrôle, elle offre une flexibilité maximale et la possibilité de produire des programmes de contrôle clés en main adaptés à votre environnement de production.

Applications centrales de la plateforme logicielle MODUS IM

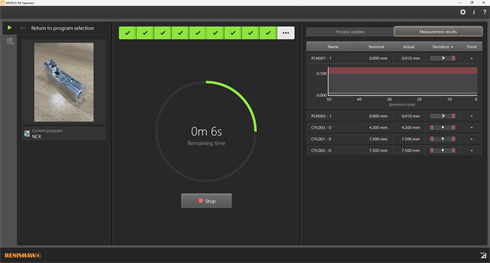

Les applications suivantes sont fournies en standard :MODUS™ IM Operator

L’application MODUS IM Operator offre une facilité d’utilisation et un contrôle exceptionnels à l’opérateur. Son interface intuitive permet aux opérateurs d’exécuter des programmes en affichant uniquement les informations convenant à leur objectif. De plus, l’interface générique renvoie vers des applications utiles de la plateforme MODUS IM et affiche des informations essentielles, telles que la durée d’exécution restante du programme, les résultats des mesures pour le cycle en cours et l’état OK/Échec des 10 cycles précédents.

Environment Manager

L’application MODUS IM Environment Manager crée un environnement virtuel précis qui reproduit les réglages réels, notamment les configurations disponibles des palpeurs de mesure, leur mode de stockage dans les racks, les stylets, les équipements de calibration et autres informations nécessaires à la génération des programmes.

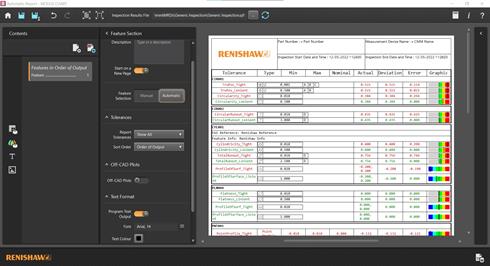

Rapports CHART

L’application autonome MODUS IM CHART simplifie l’interprétation des rapports en affichant des informations graphiques sur l’emplacement réel de la pièce à l’aide de fichiers QIF XML et du modèle CAO de la pièce. CHART crée des rapports PDF sur mesure pour l’affichage et le stockage des résultats de mesure. Toutes les tables et les tracés standard de résultats sont disponibles, ainsi qu’une fonctionnalité unique permettant de superposer des points sur un modèle CAO, réduisant ainsi le risque d’erreurs manuelles dans l’interprétation des résultats.

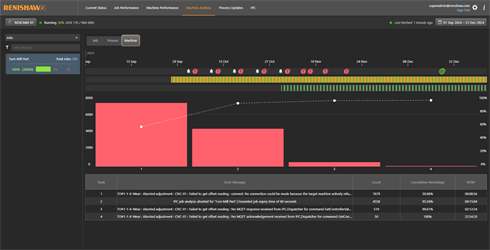

Machine Analysis

À l’aide de l’application MODUS IM Machine Analysis, les utilisateurs peuvent accéder aux données de mesure d’entités à partir de tâches individuelles et les afficher, y compris les séries de données précédentes et suivantes. Le puissant affichage visuel permet une compréhension et une analyse approfondies des données de procédé. Des erreurs peuvent se produire et, lorsqu’elles surviennent, le contrôle régulier des arrêts et des erreurs des machines permet de simplifier le processus de production et de progresser vers « l’usinage entièrement automatisé ».

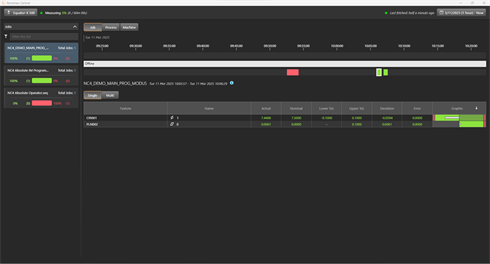

Manage Machines

L’application MODUS IM Manage Machines permet aux utilisateurs de MODUS IM de suivre et d’analyser les performances et l’efficacité des machines-outils.

Licence Manager

L’application MODUS IM Licence Manager facilite l’ajout de fonctionnalités supplémentaires, telles que le contrôle intelligent de procédé (IPC), les mises à jour de maintenance et les nouvelles fonctionnalités.

Applications d’automatisation et de contrôle de procédé pour la plateforme logicielle MODUS™ IM

MODUS™ IM Automate

L’application optionnelle MODUS IM Automate permet aux utilisateurs de configurer et d’intégrer des systèmes de mesure en atelier avec l’automatisation. Le système est intuitif et permet de charger, de contrôler et de décharger automatiquement les pièces.

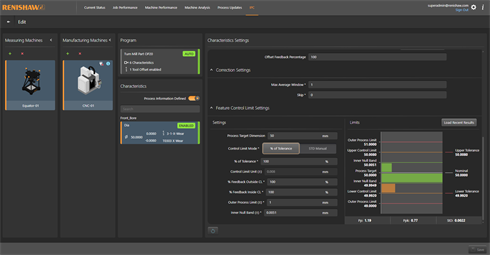

IPC - Contrôle intelligent de procédé

L’application optionnelle IPC (contrôle intelligent de procédé) pour MODUS IM offre un retour d’informations direct des données du comparateur Equator™. Son utilisation permet de mettre à jour les corrections ou les variables machine directement sur les automates des machines-outils afin de compenser les causes courantes d’instabilité des procédés, comme l’usure des outils ou la dérive thermique.

Exploitation optimale de vos données avec Renishaw Central

Tirez parti des données de votre système Equator-x grâce à Renishaw Central, notre plateforme de données de fabrication intelligente. Découvrez comment l’utiliser pour transformer dès aujourd’hui vos performances de fabrication.