현재 사용 중인 언어로는 이 페이지를 사용할 수 없습니다. Google Translate을 사용하여

자동 번역된 페이지

를 볼 수 있습니다. Renishaw에게는 이 서비스를 제공할 책임이 없으며 번역 결과를 저희가 확인하지도 않았습니다.

추가로 도움이 필요하시면

저희에게 연락해 주십시오.

Software for laser powder bed fusion (metal 3D printing) systems

Renishaw provides software solutions that enhance production efficiency and quality standards. Our tools, including QuantAM, InfiniAM, and Renishaw Central, meet modern manufacturing needs.

We are committed to providing reliable solutions to address additive manufacturing challenges. Developed with extensive industry experience, our software tools meet evolving sector demands.

Discover how Renishaw's software can support your production goals.

QuantAM

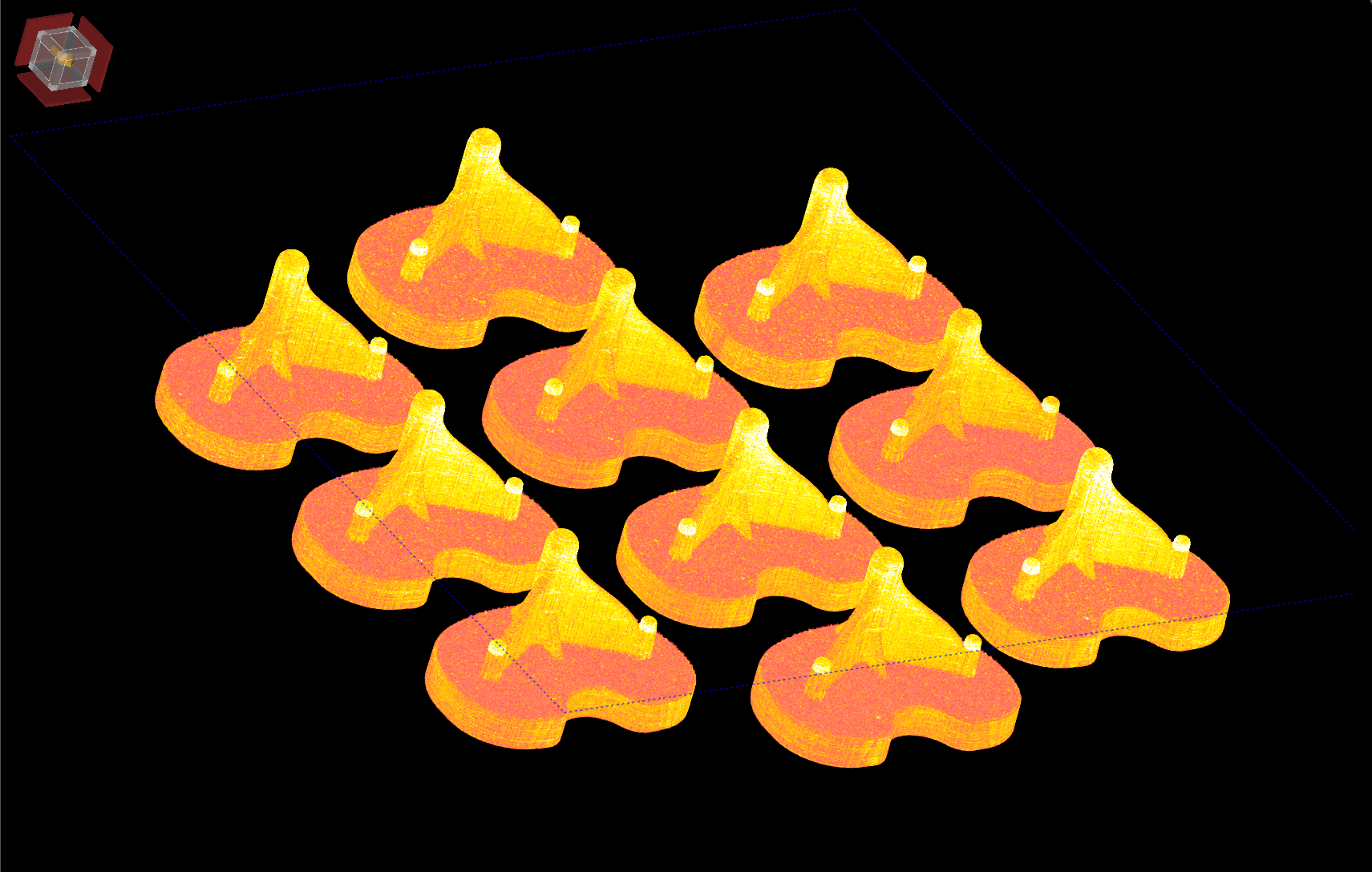

Build preparation software specifically designed for Renishaw AM platforms. It facilitates the transition from CAD models to machine-ready build files.

With QuantAM, you can modify the position of parts, add support structures, rapidly create smart toolpaths slice by slice, assign lasers, and access a range of additional advanced features, all within one intuitive application.

Build preparation software

InfiniAM Suite

Renishaw's additive manufacturing process monitoring software suite consists of InfiniAM Spectral, InfiniAM Camera and Data Hub.

InfiniAM Spectral provides real-time analysis of melt pool, plasma and energy input, providing 2D and/or 3D visualisations of the build. InfiniAM Camera offers high-resolution imaging for layer-by-layer inspection, to help detect anomalies.

DataHUB is the processing unit converts raw data into a human readable format. It also offers an API that users can integrate into their "in-house" process monitoring software.

Take control of your manufacturing process

Renishaw Central is a powerful smart manufacturing data platform designed to optimise your manufacturing processes. It collects metrology, status, and alarm data from connected devices across the shop floor, including additive manufacturing (AM) systems, on-machine measurement systems, shop floor gauging, and co-ordinate measuring machines (CMMs). By providing insight into the process performance of each workstation, Renishaw Central enables manufacturers to make informed decisions and take appropriate actions.

Take advantage of Renishaw Central to transform your additive manufacturing with enhanced data-driven insights and remote monitoring capabilities.

Renishaw Central

Open material parameters

Renishaw software optimises machine settings based on the unique melting properties of various metals, customising configurations for specific materials and geometries.

Find out more

To explore licensing options or to learn more about Renishaw's software solutions, fill out the contact us form below.