Navigation

Probe kit

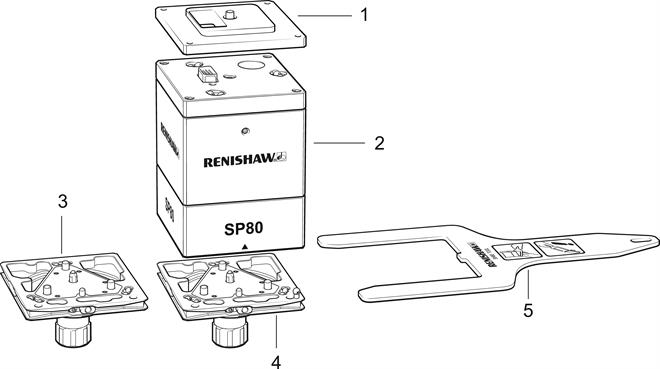

The SP80 and SP80H probe kits contain the main components detailed below, together with a probe cable, tools and a stylus.

Key | Description |

|---|---|

1 | KM80 kinematic quill mount plate (to suit 80 mm × 80 mm CMM quills) |

2 | SP80 or SP80H probe body |

3 | SH80 stylus holder |

4 | SH80K |

5 | SH80 removal tool |

KM80 kinematic quill mount plate

The SP80 and SP80H mount on the 80 mm × 80 mm quill of a CMM using the KM80 kinematic quill mount plate . The KM80 is attached to the end of the quill, and the probe is subsequently mounted to the KM80 via a kinematic joint and quick release autojoint locking mechanism.

KM6080 quill mount adaptor plate

The KM6080 is an adaptor plate that attaches to a 60 mm × 60 mm quill, but converts the 'footprint' to 80 mm × 80 mm to allow fitment of the SP80 and SP80H. It is not supplied with the standard probe kits and must be ordered separately.

SM80 shank mount adaptor plate

The SM80 shank adaptor plate is an option when the KM80 or KM6080 cannot be used, e.g. retrofit of a CMM. It is not supplied with the standard probe kits and must be ordered separately. The SM80 accepts any standard Renishaw shank and converts the output connector of the SP80 and SP80H to a touchel connector on the rear of the mount.

SP80 and SP80H probe body

The SP80 and SP80H scanning probe bodies are designed for use on direct computer controlled (DCC) CMMs. Direct fitting of the probe to the quill using the KM80 is beneficial for ultimate metrology performance, and for simple fitment to the CMM. The probe uses standard probe head cabling (so there is no requirement for new or extra cabling within the CMM).

The SP80 and SP80H design builds on the passive scanning technology of the SP600 family, but features digital scale and readheads. This enables exceptional high-accuracy scanning performance, even with long styli and extensions up to 500 mm long* and 500 g mass**. Star styli do not need to be counterbalanced, and travel in each axis is ±2.5 mm for SP80 and for SP80H is PX*** ±1.25 mm and PY*** and PZ*** ±2.5 mm.

The sensor mechanism, in both probe types, comprises an arrangement of three sets of parallel springs, one for each body axis, set in a cube - hence the body shape. The motion of the stylus is coupled to a ‘moving cube' holding graduated reflective scales - again one for each axis. The readheads are mounted on the wall of the probe and the light projected from them is reflected from the moving cube. This arrangement is known as the 'isolated optical metrology' principle, which is described in more detail in section - Isolated optical metrology principle. The motion detection system does not require any form of moving wire.

Interchangeable stylus holders (SH80) feature a repeatable mount to the probe body and permit use of the optimised measuring solution to suit the application. Automatic stylus changing of SH80s is provided by stylus changing ports (SCP80 or SCP80V).

An LED on the front face of the probe provides a visual indication of the probe status. The LED will illuminate green when power is supplied to the probe. This LED may be switched off by the user if not required and the LED colour and mode is also user configurable (the options being green, red, or both together resulting in orange).

* Longer stylus lengths may be carried subject to operating conditions - consult Renishaw for application assistance.

** Restrictions apply for SP80H see SP80H stylus carrying capability for detail.

*** Where P specifies that it is the probe's axis rather than the machine's.