Metrology software for 5-axis measurement

Powerful metrology software

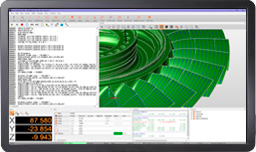

Renishaw's metrology software provides a powerful platform for CMM measurement. A configurable user interface allows native DMIS programs to be developed using multiple features such as drawing geometry, embedded dimensions, tolerance data from CAD, certified algorithms for feature measurement, evaluation and analysis.

Programs can be created and run offline directly from the CAD with on-screen probe path verification. The CMM environment, the fixture and the location of the part on the machine can all be defined. This enables full simulation of 5-axis measurement programs and minimises prove-out time required.

Future proof

The MODUS metrology software suite is a future-proof investment, ensuring guaranteed availability of the latest sensor and controller technology advancements from Renishaw. This will include future sensors for the 5-axis measurement product range, which represents the biggest step-change in measurement capability ever introduced and delivers unprecedented speed and measurement flexibility, whilst avoiding the speed versus accuracy compromises inherent in conventional techniques.