Navigation

SP25M stylus performance guidelines

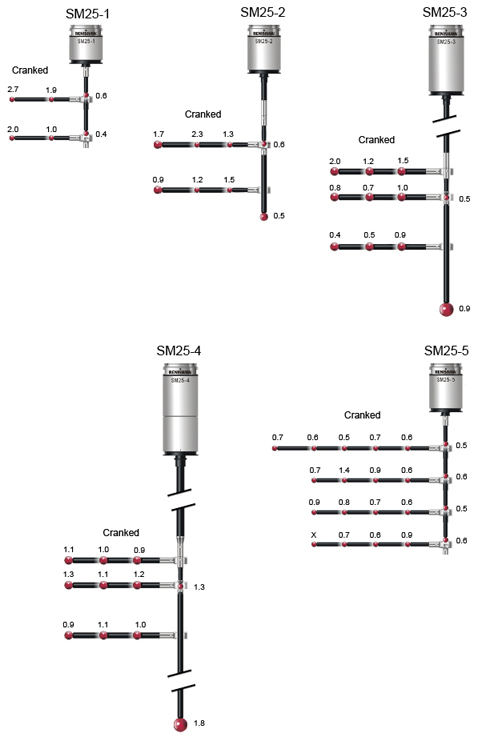

ISO 10360-2 test

Span (µm)

SS - stainless steel, CER - ceramic, GF - carbon fibre

ISO 10360-2 test - straight styli

Scanning module | Effective stylus reach | Actual M3 stylus used: | Radius error | RMS | SPAN |

|---|---|---|---|---|---|

SM25-1 | 21 mm | 21 mm / Ø4 mm / SS | -0.09 µm | 0.15 µm | 0.6 µm |

SM25-1 | 50 mm | 50 mm / Ø5 mm / CER | -0.09 µm | 0.11 µm | 0.4 µm |

SM25-2 | 51 mm | 21 mm / Ø4 mm / SS | -0.4 µm | 0.15 µm | 0.6 µm |

SM25-2 | 105 mm | 75 mm / Ø6 mm / GF | -0.26 µm | 0.13 µm | 0.5 µm |

SM25-3 | 121 mm | 21 mm / Ø4 mm / SS | -0.44 µm | 0.14 µm | 0.5 µm |

SM25-3 | 200 mm | 100 mm / Ø6 mm / GF | -0.19 µm | 0.24 µm | 0.9 µm |

SM25-4 | 221 mm | 21 mm / Ø5 mm / SS | 0.1 µm | 0.34 µm | 1.3 µm |

SM25-4 | 400 mm | 200 mm / Ø8 mm / GF | 0.4 µm | 0.42 µm | 1.8 µm |

SM25-5 | 21 mm | 21 mm / Ø4 mm / SS | -0.4 µm | 0.12 µm | 0.5 µm |

SM25-5 | 105 mm | 100 mm / Ø5 mm / CF | -0.37 µm | 0.20 µm | 0.68 µm |

ISO 10360-2 test - cranked styli

Scanning module | Crank configuration | Actual M3 stylus used: | Radius error | RMS | SPAN |

|---|---|---|---|---|---|

SM25-1 | 25 mm 'down' 28 mm 'out' | 21 mm / Ø4 mm / SS | 0.1 µm | 0.48 µm | 1.9 µm |

SM25-1 | 25 mm 'down' 57.5 mm 'out' | 50 mm / Ø5 mm / CER | -0.04 µm | 0.56 µm | 2.7 µm |

SM25-1 | 55 mm 'down' 28 mm 'out' | 21 mm / Ø4 mm / SS | 0.15 µm | 0.21 µm | 1 µm |

SM25-1 | 55 mm 'down' 57.5 mm 'out' | 50 mm / Ø5 mm / CER | 0.03 µm | 0.34 µm | 2 µm |

SM25-2 | 55 mm 'down' 28 mm 'out' | 21 mm / Ø4 mm / SS | 0.54 µm | 0.38 µm | 1.3 µm |

SM25-2 | 55 mm 'down' 57.5 mm 'out' | 50 mm / Ø5 mm / CER | 0.19 µm | 0.61 µm | 2.3 µm |

SM25-2 | 55 mm 'down' 83 mm 'out' | 75 mm / Ø6 mm / GF | 0.07 µm | 0.53 µm | 1.7 µm |

SM25-2 | 85 mm 'down' 28 mm 'out' | 21 mm / Ø4 mm / SS | 0.35 µm | 0.34 µm | 1.5 µm |

SM25-2 | 85 mm 'down' 57.5 mm 'out' | 50 mm / Ø5 mm / CER | 0.05 µm | 0.23 µm | 1.2 µm |

SM25-2 | 85 mm 'down' 83 mm 'out' | 75 mm / Ø6 mm / GF | 0.09 µm | 0.25 µm | 0.9 µm |

SM25-3 | 105 mm 'down' 28 mm 'out' | 21 mm / Ø4 mm / SS | 0.3 µm | 0.41 µm | 1.5 µm |

SM25-3 | 105 mm 'down' 57.5 mm 'out' | 50 mm / Ø5 mm / CER | -0.23 µm | 0.31 µm | 1.2 µm |

SM25-3 | 105 mm 'down' 83 mm 'out' | 75 mm / Ø6 mm / GF | 0.66 µm | 0.56 µm | 2 µm |

SM25-3 | 125 mm 'down' 28 mm 'out' | 21 mm / Ø4 mm / SS | 0.14 µm | 0.28 µm | 1 µm |

SM25-3 | 125 mm 'down' 57.5 mm 'out' | 50 mm / Ø5 mm / CER | 0.12 µm | 0.16 µm | 0.7 µm |

SM25-3 | 125 mm 'down' 83 mm 'out' | 75 mm / Ø6 mm / GF | 0 µm | 0.22 µm | 0.8 µm |

SM25-3 | 155 mm 'down' 28 mm 'out' | 21 mm / Ø4 mm / SS | 0.28 µm | 0.25 µm | 0.9 µm |

SM25-3 | 155 mm 'down' 57.5 mm 'out' | 50 mm / Ø5 mm / CER | 0.06 µm | 0.15 µm | 0.5 µm |

SM25-3 | 155 mm 'down' 83 mm 'out' | 75 mm / Ø6 mm / GF | 0.04 µm | 0.1 µm | 0.4 µm |

SM25-4 | 205 mm 'down' 28 mm 'out' | 21 mm / Ø4 mm / SS | 0.01 µm | 0.24 µm | 0.9 µm |

SM25-4 | 205 mm 'down' 57.5 mm 'out' | 50 mm / Ø5 mm / CER | 0.19 µm | 0.21 µm | 1 µm |

SM25-4 | 205 mm 'down' 83 mm 'out' | 75 mm / Ø6 mm / GF | -0.11 µm | 0.28 µm | 1.1 µm |

SM25-4 | 225 mm 'down' 28 mm 'out' | 21 mm / Ø4 mm / SS | 0.01 µm | 0.21 µm | 1.2 µm |

SM25-4 | 225 mm 'down' 57.5 mm 'out' | 50 mm / Ø5 mm / CER | 0.18 µm | 0.29 µm | 1.1 µm |

SM25-4 | 225 mm 'down' 83 mm 'out' | 75 mm / Ø6 mm / GF | 0.05 µm | 0.3 µm | 1.3 µm |

SM25-4 | 255 mm 'down' 28 mm 'out' | 21 mm / Ø4 mm / SS | -0.07 µm | 0.25 µm | 1 µm |

SM25-4 | 255 mm 'down' 57.5 mm 'out' | 50 mm / Ø5 mm / CER | 0.1 µm | 0.34 µm | 1.1 µm |

SM25-4 | 255 mm 'down' 83 mm 'out' | 75 mm / Ø6 mm / GF | -0.1 µm | 0.21 µm | 0.9 µm |

Test setup criteria

Test site | Renishaw UK |

|---|---|

Styli used | Renishaw's M3 stylus range |

CMM specification | U3 = 0.48 µm + L / 1000 |

CMM controller | Renishaw's UCC2 |

Probe calibration | Renishaw's third order polynomial calibration method |

Data filter used | Harmonic simple cut off order = 60 UPR (undulations per revolution) |

Artefacts used | Ø25 mm (nom) calibration sphere (for the ISO 10360 Part 2 / Part 4 tests) Ø50 mm (nom) ring gauge (for the ring gauge scan tests) |

Scanning speed | 5 mm/s (for the ISO 10360 Part 4 and ring gauge scan tests) |

Touch speed | 5 mm/s (for the ISO 10360 Part 2 tests) |

Back off speed | 1 mm/s (for the ISO 10360 Part 2 tests) |

Bi-directional scans | The effect of probe misalignment and contact friction will result in radius changes with scanning direction if a suitable calibration procedure is not used. Mechanical hysteresis within a probe mechanism is best demonstrated by a bi-directional scan. Therefore, Renishaw have decided to take the high integrity approach of quoting ring gauge metrology using bi-directional scan data to demonstrate the performance of the Renishaw probe and calibration method. |

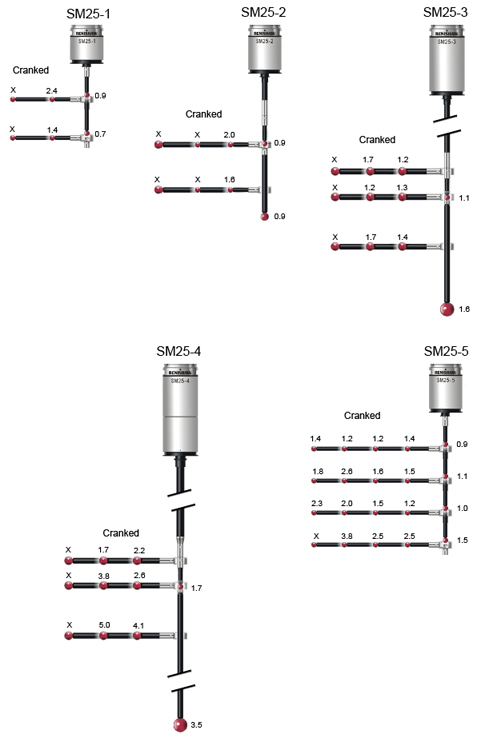

ISO 10360-4 test

Filtered MPETHN (60 UPR µm)

SS - stainless steel, CER - ceramic, GF - carbon fibre

ISO 10360-4 test - straight styli

Scanning module | Effective stylus reach | Actual M3 stylus used: | ISO MPETHN data raw | ISO MPETHN data filtered | ISO Diff data raw | ISO Diff data filtered | Stylus tip deflection | Time taken |

|---|---|---|---|---|---|---|---|---|

SM25-1 | 21 mm | 21 mm / Ø4 mm / SS | 1.4 µm | 0.9 µm | 0.8 µm | 0.5 µm | 0.2 mm | 1' 07" |

SM25-1 | 50 mm | 50 mm / Ø5 mm / CER | 1.5 µm | 0.7 µm | 0.8 µm | 0.4 µm | 0.2 mm | 1' 08" |

SM25-2 | 51 mm | 21 mm / Ø4 mm / SS | 1.5 µm | 0.9 µm | 0.8 µm | 0.5 µm | 0.2 mm | 1' 07" |

SM25-2 | 105 mm | 75 mm / Ø6 mm / GF | 1.6 µm | 0.9 µm | 0.9 µm | 0.5 µm | 0.2 mm | 1' 14" |

SM25-3 | 121 mm | 21 mm / Ø4 mm / SS | 1.9 µm | 1.1 µm | 1.0 µm | 0.6 µm | 0.2 mm | 1' 07" |

SM25-3 | 200 mm | 100 mm / Ø6 mm / GF | 3.2 µm | 1.6 µm | 2.1 µm | 1.0 µm | 0.2 mm | 1' 16" |

SM25-4 | 221 mm | 21 mm / Ø5 mm / SS | 2.8 µm | 1.7 µm | 1.5 µm | 0.9 µm | 0.2 mm | 1' 14" |

SM25-4 | 400 mm | 200 mm / Ø8 mm / GF | 6.4 µm | 3.5 µm | 3.7 µm | 0.9 µm | 0.2 mm | 1' 17" |

SM25-5 | 21 mm | 21 mm / Ø4 mm / SS | 2.1 µm | 0.9 µm | 1.1 µm | 0.5 µm | 0.2 mm | 1' 08" |

SM25-5 | 105 mm | 100 mm / Ø5 mm / CF | 2.8 µm | 1.5 µm | 1.5 µm | 1.0 µm | 0.2 mm | 1' 14" |

ISO 10360-4 - cranked styli

Scanning module | Crank configuration | Actual M3 stylus used: | ISO MPETHN data raw | ISO MPETHN data filtered | ISO Diff data raw | ISO Diff data filtered | Stylus tip deflection | Time taken |

|---|---|---|---|---|---|---|---|---|

SM25-1 | 25 mm 'down' 28 mm 'out' | 21 mm / Ø4 mm / SS | 3.1 µm | 2.4 µm | 1.7 µm | 1.2 µm | 0.2 mm | 1' 11" |

SM25-1 | 55 mm 'down' 28 mm 'out' | 21 mm / Ø4 mm / SS | 4.8 µm | 1.4 µm | 2.4 µm | 0.8 µm | 0.2 mm | 1' 09" |

SM25-2 | 55 mm 'down' 28 mm 'out' | 21 mm / Ø4 mm / SS | 2.5 µm | 2 µm | 1.5 µm | 1.3 µm | 0.2 mm | 1' 09" |

SM25-2 | 85 mm 'down' 28 mm 'out' | 21 mm / Ø4 mm / SS | 2.8 µm | 1.6 µm | 1.7 µm | 1 µm | 0.2 mm | 1' 08" |

SM25-3 | 105 mm 'down' 28 mm 'out' | 21 mm / Ø4 mm / SS | 1.8 µm | 1.2 µm | 1.2 µm | 0.8 µm | 0.2 mm | 1' 12" |

SM25-3 | 105 mm 'down' 57.5 mm 'out' | 50 mm / Ø5 mm / CER | 2.3 µm | 1.7 µm | 1.3 µm | 1 µm | 0.2 mm | 1' 12" |

SM25-3 | 125 mm 'down' 28 mm 'out' | 21 mm / Ø4 mm / SS | 2.1 µm | 1.3 µm | 1.2 µm | 0.8 µm | 0.2 mm | 1' 12" |

SM25-3 | 125 mm 'down' 57.5 mm 'out' | 50 mm / Ø5 mm / CER | 2.2 µm | 1.2 µm | 1.3 µm | 0.7 µm | 0.2 mm | 1' 11" |

SM25-3 | 155 mm 'down' 28mm 'out' | 21 mm / Ø4 mm / SS | 2.7 µm | 1.4 µm | 1.9 µm | 1.2 µm | 0.35 mm | 1' 16" |

SM25-3 | 155 mm 'down' 57.5 mm 'out' | 50 mm / Ø5 mm / CER | 2.6 µm | 1.7 µm | 1.7 µm | 1.1 µm | 0.35 mm | 1' 16" |

SM25-4 | 205 mm 'down' 28 mm 'out' | 21 mm / Ø4 mm / SS | 3 µm | 2.2 µm | 1.7 µm | 1.3 µm | 0.2 mm | 1' 11" |

SM25-4 | 205 mm 'down' 57.5 mm 'out' | 50 mm / Ø5 mm / CER | 2.6 µm | 1.7 µm | 1.8 µm | 1.2 µm | 0.2 mm | 1' 17" |

SM25-4 | 225 mm 'down' 28 mm 'out' | 21 mm / Ø4 mm / SS | 3.2 µm | 2.6 µm | 2.0 µm | 1.9 µm | 0.2 mm | 1' 16" |

SM25-4 | 225 mm 'down' 57.5 mm 'out' | 50 mm / Ø5 mm / CER | 4.6 µm | 3.8 µm | 3.5 µm | 3.2 µm | 0.2 mm | 1' 25" |

SM25-4 | 255 mm 'down' 28 mm 'out' | 21 mm / Ø4 mm / SS | 5 µm | 4.1 µm | 3 µm | 2.6 µm | 0.2 mm | 1' 10" |

SM25-4 | 255 mm 'down' 57.5 mm 'out' | 50 mm / Ø5 mm / CER | 8.3 µm | 5 µm | 4.9 µm | 2.7 µm | 0.2 mm | 1' 10" |

Test setup criteria

Test site | Renishaw UK |

|---|---|

Styli used | Renishaw's M3 stylus range |

CMM specification | U3 = 0.48 µm + L / 1000 |

CMM controller | Renishaw's UCC2 |

Probe calibration | Renishaw's third order polynomial calibration method |

Data filter used | Harmonic simple cut off order = 60 UPR (undulations per revolution) |

Artefacts used | Ø25 mm (nom) calibration sphere (for the ISO 10360 Part 2 / Part 4 tests) Ø50 mm (nom) ring gauge (for the ring gauge scan tests) |

Scanning speed | 5 mm/s (for the ISO 10360 Part 4 and ring gauge scan tests) |

Touch speed | 5 mm/s (for the ISO 10360 Part 2 tests) |

Back off speed | 1 mm/s (for the ISO 10360 Part 2 tests) |

Bi-directional scans | The effect of probe misalignment and contact friction will result in radius changes with scanning direction if a suitable calibration procedure is not used. Mechanical hysteresis within a probe mechanism is best demonstrated by a bi-directional scan. Therefore, Renishaw have decided to take the high integrity approach of quoting ring gauge metrology using bi-directional scan data to demonstrate the performance of the Renishaw probe and calibration method. |

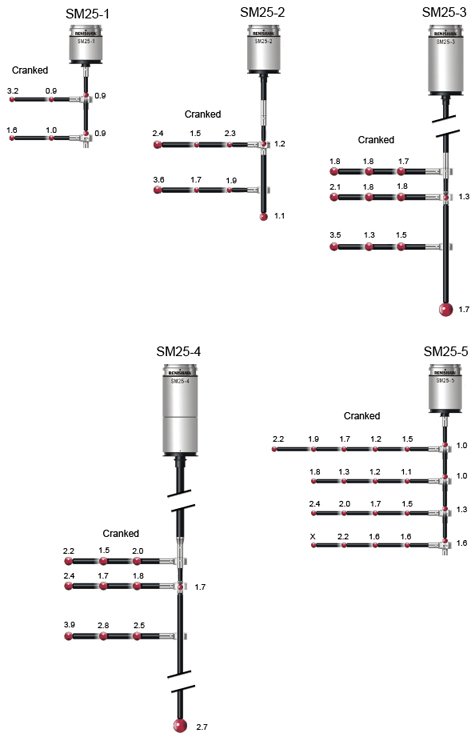

Bi-directional ring gauge

Filtered span (60 UPR µm)

SS - stainless steel, CER - ceramic, GF - carbon fibre

Bi-directional ring gauge scan test - straight styli

Scanning module | Effective stylus reach | Actual M3 stylus used: | RMS data raw | RMS data filtered | SPAN data raw | SPAN data filtered | Stylus tip deflection | Raw data pts |

|---|---|---|---|---|---|---|---|---|

SM25-1 | 21 mm | 21 mm / Ø4 mm / SS | 0.23 µm | 0.19 µm | 1.5 µm | 0.9 µm | 0.35 mm | 2857 |

SM25-1 | 50 mm | 50 mm / Ø5 mm / CER | 0.24 µm | 0.17 µm | 1.5 µm | 0.9 µm | 0.2 mm | 2794 |

SM25-2 | 51 mm | 21 mm / Ø4 mm / SS | 0.24 µm | 0.21 µm | 1.6 µm | 1.2 µm | 0.2 mm | 2858 |

SM25-2 | 105 mm | 75 mm / Ø6 mm / GF | 0.24 µm | 0.18 µm | 2.0 µm | 1.1 µm | 0.2 mm | 2609 |

SM25-3 | 121 mm | 21 mm / Ø4 mm / SS | 0.38 µm | 0.20 µm | 2.2 µm | 1.3 µm | 0.2 mm | 2857 |

SM25-3 | 200 mm | 100 mm / Ø6 mm / GF | 0.38 µm | 0.27 µm | 4.1 µm | 1.7 µm | 0.2 mm | 2484 |

SM25-4 | 221 mm | 21 mm / Ø5 mm / SS | 0.40 µm | 0.30 µm | 3.0 µm | 1.7 µm | 0.2 mm | 2462 |

SM25-4 | 400 mm | 200 mm / Ø8 mm / GF | 0.80 µm | 0.50 µm | 5.7 µm | 2.7 µm | 0.2 mm | 2388 |

SM25-5 | 21 mm | 21 mm / Ø4 mm / SS | 0.21 µm | 0.18 µm | 2.1 µm | 1.0 µm | 0.2 mm | 2831 |

SM25-5 | 105 mm | 100 mm / Ø5 mm / CF | 0.48 µm | 0.28 µm | 4.2 µm | 1.6 µm | 0.2 mm | 2643 |

Bi-directional ring gauge scan test - cranked styli

Scanning module | Crank configuration | Actual M3 stylus used: | RMS data raw | RMS data filtered | SPAN data raw | SPAN data filtered | Stylus tip deflection | Raw data points |

|---|---|---|---|---|---|---|---|---|

SM25-1 | 25 mm 'down' 28 mm 'out' | 21 mm / Ø4 mm / SS | 0.26 µm | 0.19 µm | 1.9 µm | 0.9 µm | 0.2 mm | 2858 |

SM25-1 | 25 mm 'down' 57.5 mm 'out' | 50 mm / Ø5 mm / CER | 0.62 µm | 0.56 µm | 6 µm | 3.2 µm | 0.2 mm | 2794 |

SM25-1 | 55 mm 'down' 28 mm 'out' | 21 mm / Ø4 mm / SS | 0.28 µm | 0.16 µm | 3 µm | 1 µm | 0.2 mm | 2868 |

SM25-1 | 55 mm 'down' 57.5 mm 'out' | 50 mm / Ø5 mm / CER | 0.36 µm | 0.24 µm | 4.9 µm | 1.6 µm | 0.2 mm | 2796 |

Scanning module | Crank configuration | Actual M3 stylus used: | RMS data raw | RMS data filtered | SPAN data raw | SPAN data filtered | Stylus tip deflection | Raw data points |

|---|---|---|---|---|---|---|---|---|

SM25-2 | 55 mm 'down' 28 mm 'out' | 21 mm / Ø4 mm / SS | 0.6 µm | 0.56 µm | 3.1 µm | 2.3 µm | 0.2 mm | 2858 |

SM25-2 | 55 mm 'down' 57.5 mm 'out' | 50 mm / Ø5 mm / CER | 0.33 µm | 0.26 µm | 2.8 µm | 1.5 µm | 0.2 mm | 2857 |

SM25-2 | 55 mm 'down' 83 mm 'out' | 75 mm / Ø6 mm / GF | 0.55 µm | 0.47 µm | 4.1 µm | 2.4 µm | 0.35 mm | 2733 |

SM25-2 | 85 mm 'down' 28 mm 'out' | 21 mm / Ø4 mm / SS | 0.35 µm | 0.24 µm | 4.5 µm | 1.9 µm | 0.2 mm | 2858 |

SM25-2 | 85 mm 'down' 57.5 mm 'out' | 50 mm / Ø5 mm / CER | 0.45 µm | 0.36 µm | 3 µm | 1.7 µm | 0.2 mm | 2795 |

SM25-2 | 85 mm 'down' 83 mm 'out' | 75 mm / Ø6 mm / GF | 0.75 µm | 0.6 µm | 6.1 µm | 3.6 µm | 0.2 mm | 2734 |

SM25-3 | 105 mm 'down' 28 mm 'out' | 21 mm / Ø4 mm / SS | 0.4 µm | 0.35 µm | 2.3 µm | 1.7 µm | 0.2 mm | 2858 |

SM25-3 | 105 mm 'down' 57.5 mm 'out' | 50 mm / Ø5 mm / CER | 0.44 µm | 0.38 µm | 2.7 µm | 1.8 µm | 0.2 mm | 2858 |

SM25-3 | 105 mm 'down' 83 mm 'out' | 75 mm / Ø6 mm / GF | 0.42 µm | 0.36 µm | 3 µm | 1.8 µm | 0.2 mm | 2733 |

SM25-3 | 125 mm 'down' 28 mm 'out' | 21 mm / Ø4 mm / SS | 0.47 µm | 0.42 µm | 2.7 µm | 1.8 µm | 0.2 mm | 2856 |

SM25-3 | 125 mm 'down' 57.5 mm 'out' | 50 mm / Ø5 mm / CER | 0.47 µm | 0.35 µm | 2.7 µm | 1.8 µm | 0.2 mm | 2856 |

SM25-3 | 125 mm 'down' 83 mm 'out' | 75 mm / Ø6 mm / GF | 0.55 µm | 0.46 µm | 3.5 µm | 2.1 µm | 0.35 mm | 2732 |

SM25-3 | 155 mm 'down' 28 mm 'out' | 21 mm / Ø4 mm / SS | 0.38 µm | 0.31 µm | 2.6 µm | 1.5 µm | 0.2 mm | 2858 |

SM25-3 | 155 mm 'down' 57.5 mm 'out' | 50 mm / Ø5 mm / CER | 0.37 µm | 0.27 µm | 2.9 µm | 1.3 µm | 0.2 mm | 2858 |

SM25-3 | 155 mm 'down' 83 mm 'out' | 75 mm / Ø6 mm / GF | 1.01 µm | 0.69 µm | 11.8 µm | 3.5 µm | 0.2 mm | 2734 |

Scanning module | Crank configuration | Actual M3 stylus used: | RMS data raw | RMS data filtered | SPAN data raw | SPAN data filtered | Stylus tip deflection | Raw data points |

|---|---|---|---|---|---|---|---|---|

SM25-4 | 205 mm 'down' 28 mm 'out' | 21 mm / Ø4 mm / SS | 0.45 µm | 0.38 µm | 2.6 µm | 2 µm | 0.2 mm | 1439 |

SM25-4 | 205 mm 'down' 57.5 mm 'out' | 50 mm / Ø5 mm / CER | 0.38 µm | 0.26 µm | 2.5 µm | 1.5 µm | 0.2 mm | 1440 |

SM25-4 | 205 mm 'down' 83 mm 'out' | 75 mm / Ø6 mm / GF | 0.51 µm | 0.34 µm | 4.2 µm | 2.2 µm | 0.2 mm | 1376 |

SM25-4 | 225 mm 'down' 28 mm 'out' | 21 mm / Ø4 mm / SS | 0.41 µm | 0.32 µm | 2.7 µm | 1.8 µm | 0.2 mm | 1438 |

SM25-4 | 225 mm 'down' 57.5 mm 'out' | 50 mm / Ø5 mm / CER | 0.42 µm | 0.3 µm | 2.6 µm | 2.7 µm | 0.2 mm | 1438 |

SM25-4 | 225 mm 'down' 83 mm 'out' | 75 mm / Ø6 mm / GF | 0.65 µm | 0.48 µm | 5.1 µm | 2.4 µm | 0.35 mm | 2731 |

SM25-4 | 255 mm 'down' 28 mm 'out' | 21 mm / Ø4 mm / SS | 0.67 µm | 0.59 µm | 3.6 µm | 2.5 µm | 0.2 mm | 2858 |

SM25-4 | 255 mm 'down' 57.5 mm 'out' | 50 mm / Ø5 mm / CER | 0.69 µm | 0.55 µm | 5.9 µm | 2.8 µm | 0.2 mm | 2794 |

SM25-4 | 255 mm 'down' 83 mm 'out' | 75 mm / Ø6 mm / GF | 0.99 µm | 0.75 µm | 8.5 µm | 3.9 µm | 0.2 mm | 2730 |

Test setup criteria

Test site | Renishaw UK |

|---|---|

Styli used | Renishaw's M3 stylus range |

CMM specification | U3 = 0.48 µm + L / 1000 |

CMM controller | Renishaw's UCC2 |

Probe calibration | Renishaw's third order polynomial calibration method |

Data filter used | Harmonic simple cut off order = 60 UPR (undulations per revolution) |

Artefacts used | Ø25 mm (nom) calibration sphere (for the ISO 10360 Part 2 / Part 4 tests) Ø50 mm (nom) ring gauge (for the ring gauge scan tests) |

Scanning speed | 5 mm/s (for the ISO 10360 Part 4 and ring gauge scan tests) |

Touch speed | 5 mm/s (for the ISO 10360 Part 2 tests) |

Back off speed | 1 mm/s (for the ISO 10360 Part 2 tests) |

Bi-directional scans | The effect of probe misalignment and contact friction will result in radius changes with scanning direction if a suitable calibration procedure is not used. Mechanical hysteresis within a probe mechanism is best demonstrated by a bi-directional scan. Therefore, Renishaw have decided to take the high integrity approach of quoting ring gauge metrology using bi-directional scan data to demonstrate the performance of the Renishaw probe and calibration method. |