Navigation

Air supply

SP80 and SP80H units built after September 2010 have the ability to fit the air purge option. From this date all new probes have been supplied with a suitable push fit connector as part of the standard probe kit.

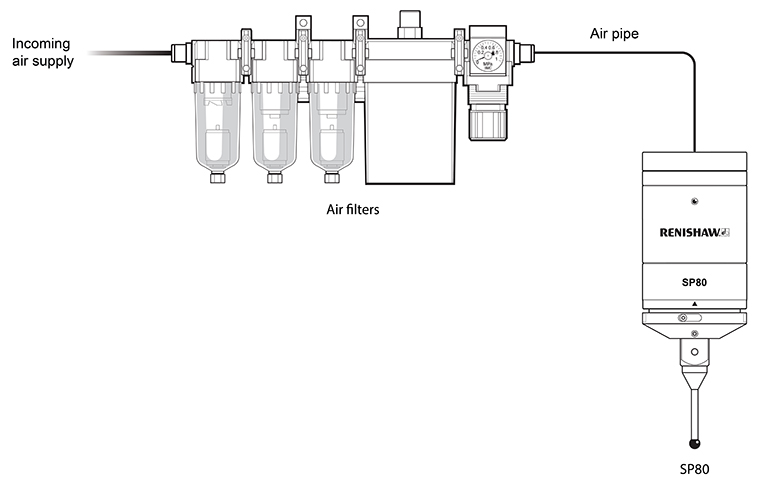

The SP80 and SP80H probes are supplied with a blanked off air purge hole. If the probe is to be operated in an environment where oil mist or other heavy vapours are present it is essential that an air supply is used to maintain positive purging of any contamination from the interior of the probe.

The air purge system requires an air filter. This can be purchased directly from Renishaw (Renishaw part number A-3060-0070) or a suitable alternative can be used.

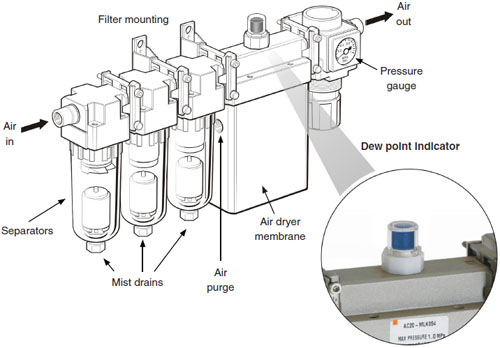

Air filter maintenance

WARNING: It is vital that the air filters used for SP80 and SP80H air purge meet the specification detailed below and that the filter unit is maintained to the manufacturer's specification.

To maintain the air quality:

1. Ensure the air provided to the filtration system meets the specification given.

Incoming air supply specification:

Air pressure | 1 to 2 bar* |

Air consumption | 15 to 25 litres per minute |

BS ISO 8537-1:2010 [4:4:4] | |

Particle size | 15 μm |

Dirt concentration | 8 mg / m³ |

Dew point | +3 °C |

Oil | 5 mg / m³ |

Please ask the installer for the specification.

It is important that the air supply to the probe is maintained to ensure that the positive purging is effective.

2. Regularly monitor the dew point indicator (see image below) and follow the instructions given in the table.

For more information please visit the air filtration manufacturer's website http://www.smcpneumatics.com and search for IDG5 filters. (Please refer to the section 'Air filter service kits' for details on air filter service kit part numbers).

Dew point indications and maintenance instructions

Grain colour | Causes | Solutions |

Blue / green | Normal operation. | No action required. |

Pink / yellow | Water and oil flow into membrane air dryer. | 1) Check and replace filters if necessary. 2) Check condition of inlet air for excess oil or water. |

NOTE: The grains may be pink / yellow on delivery and can take up to 1½ hours to turn blue / green when air is connected.

Air filter service kits

The Renishaw filter service kit (M-3060-0933) contains:

SMC part number | Description | Quantity |

AF20P-060S | 5 μm filter element for use with AF20 unit | 1 |

AFM20P-060AS | 0.3 μm filter element for use with AFM20 unit | 1 |

AFD20P-060AS | 0.01 μm filter element for use with AFD20 unit | 1 |

We recommend that the above filter kit is replaced every two years.

The Renishaw membrane dryer service kit (M-3060-0943) contains:

SMC part number | Description | Quantity |

IDG-EL5 | Membrane module kit for use with IDG5 unit | 1 |

IDG-DP01 | Dew point indicator kit for use with IDG5 unit | 1 |

We recommend that the above filter kit is replaced every four years.