SupaTouch technology

Automatic measurement cycle optimisation for machine tools.

SupaTouch technology - intelligent probing cycle optimisation

SupaTouch technology is embedded within the latest versions of Inspection Plus software and intelligently delivers the fastest possible cycle time without compromising accuracy and repeatability.

A simple optimisation routine calculates the measurement capability of the system to determine the optimum measuring and positioning feedrates for the probe.

Minimise cycle time

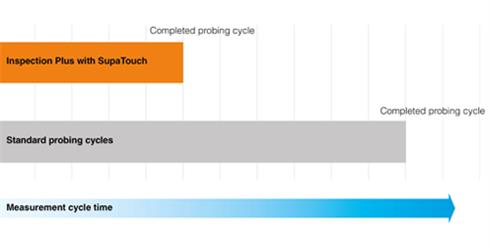

SupaTouch makes intelligent in-process decisions to deliver significant improvements in cycle time based on the capability of the machine tool.

Optimised feedrates

Calculation of the fastest possible measuring and positioning feedrates for the machine tool.

Automatic measurement selection

Automatic selection of a one-touch or two-touch measurement depending on what will be fastest for that specific measurement point.

Probe back-off distance

Automatic calculation of the optimised probe back-off distance leads to further improvements in cycle time.

Improved metrology

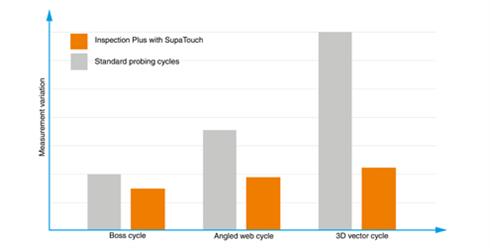

Inspection Plus with SupaTouch technology significantly improves metrology.

Ability to distinguish between the real and electronic probe length (length when triggered). This provides a significant advantage when using 3D vector probing cycles as it ensures the probe is correctly positioned for each measurement.

Accurate metrology in all directions is made possible by automated, 'on-the-fly' calculation of the stylus ball radius for every measurement move.

Measurements taken in the probe acceleration and deceleration zones are remeasured at a constant velocity to ensure accurate metrology.

From simple prismatic to more complex 3D cycles, Inspection Plus with SupaTouch can improve accuracy and repeatability in all directions. The image below illustrates typical improvements that can be achieved.

Next steps

Contact your local sales representatives if you think SupaTouch technology is right for you.

Learn more

-

Flyer: SupaTouch technology

Flyer: SupaTouch technology

Inspection Plus with SupaTouch is a software application designed to calibrate your machine, controller and probe as a system and on the fly, intelligently select either one-touch or two-touch measurement with the fastest possible positioning and measurement feedrates for your application.

-

Data sheet: Probe software for machine tools : programs and features

Data sheet: Probe software for machine tools : programs and features

H-2000-2298 - Overview of the available range of macro software packages.

-

Brochure: Powerful and intuitive machine tool probing software

Brochure: Powerful and intuitive machine tool probing software

A Brochure containing all machine tool probing software and complimentary machine tool calibration software solutions offered by Renishaw.

-

Technical specifications: Probing systems for CNC machine tools

Technical specifications: Probing systems for CNC machine tools

The type of probing system that you need will depend on your machine tool and the nature of the probing application. This document focuses on the main applications for probing on machine tools. It contains an introduction to the use of probing for each application, plus guidance on the selection of the most appropriate system and technical information about each probe.