Navigation

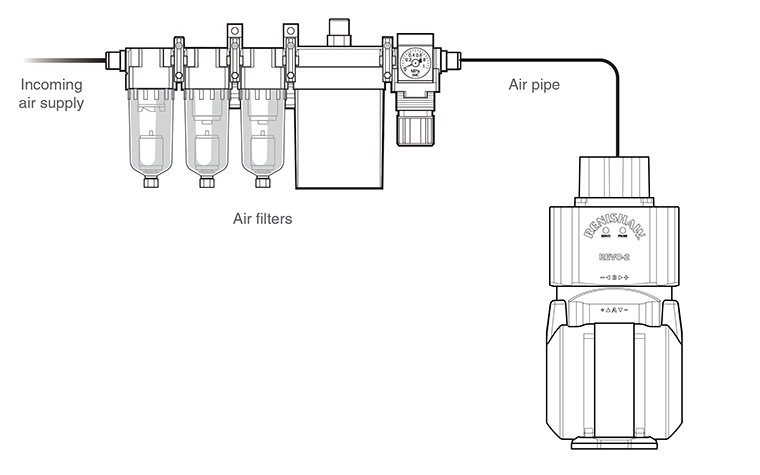

Air supply

It is important that the air supply to the head is maintained while the head is powered as the air supplies the bearings and provides air for thermal management.

CAUTION: Air supply pressure at the input to the air filters should be a maximum of 8.5 bar and at the head should be a maximum of 5.5 bar.

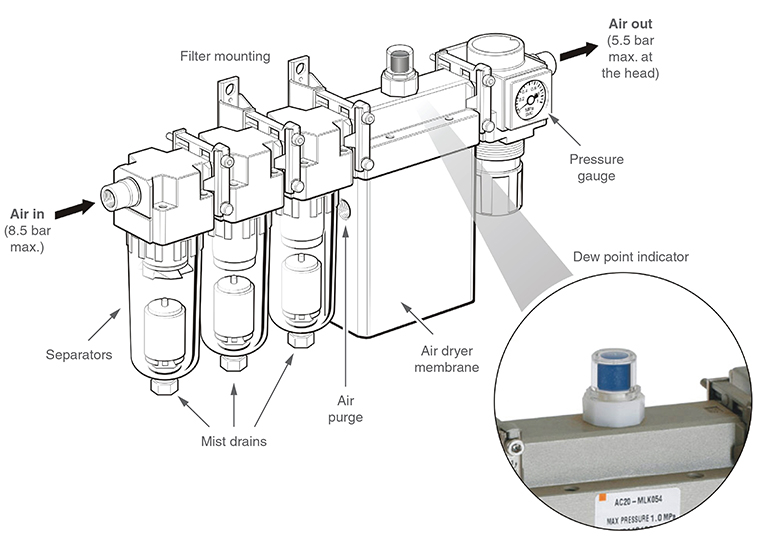

Air filter maintenance

WARNING: It is vital that the supplied air filters are used for REVO-2 and that the filter unit is maintained to the filter manufacturer's specification. Failure to comply with the specification will invalidate the warranty and is likely to result in permanent damage to the REVO-2 head requiring replacement at full cost.

To maintain the air quality:

1. Ensure the air provided to the filtration system meets the specification given.

Incoming air supply specification:

Air pressure | 5 bar - 8.5 bar* |

Air consumption | Up to 50 litres per minute |

BS ISO 8537-1:2010 [4:4:4] | |

Particle size | 15 μm |

Dirt concentration | 8 mg / m³ |

Dew point | +3 °C |

Oil | 5 mg / m³ |

* NOTE: The exact values are dependent on the inherent characteristics of the air pipe between the air filters and the REVO-2 head. Please ask the installer for the specification.

If the air pressure falls outside the range given, the head metrology results will be affected.

CAUTION: Air supply pressure at the input to the air filters should be a maximum of 8.5 bar and at the head should be a maximum of 5.5 bar.

2. Regularly monitor the dew point indicator (see image below) and follow the instructions given in the table.

For more information please visit the air filtration manufacturer's website http://www.smcpneumatics.com and search for IDG5 filters. (Please refer to the section 'REVO air filter service kits' for details on air filter service kit part numbers).

Dew point indications and maintenance instructions

Grain colour | Causes | Solutions |

Blue / green | Normal operation. | No action required. |

Pink / yellow | Water and oil flow into membrane air dryer. | 1) Check and replace filters if necessary. 2) Check condition of inlet air for excess oil or water. |

NOTE: The grains may be pink / yellow on delivery and can take up to 1½ hours to turn blue / green when air is connected.

Air filter service kits

The Renishaw filter service kit (M-3060-0933) contains:

SMC part number | Description | Quantity |

AF20P-060S | 5 μm filter element for use with AF20 unit | 1 |

AFM20P-060AS | 0.3 μm filter element for use with AFM20 unit | 1 |

AFD20P-060AS | 0.01 μm filter element for use with AFD20 unit | 1 |

We recommend that the above filter kit is replaced every two years.

The Renishaw membrane dryer service kit (M-3060-0943) contains:

SMC part number | Description | Quantity |

IDG-EL5 | Membrane module kit for use with IDG5 unit | 1 |

IDG-DP01 | Dew point indicator kit for use with IDG5 unit | 1 |

We recommend that the above filter kit is replaced every four years.