Navigation

Fitting heavy-duty legs to the MRS

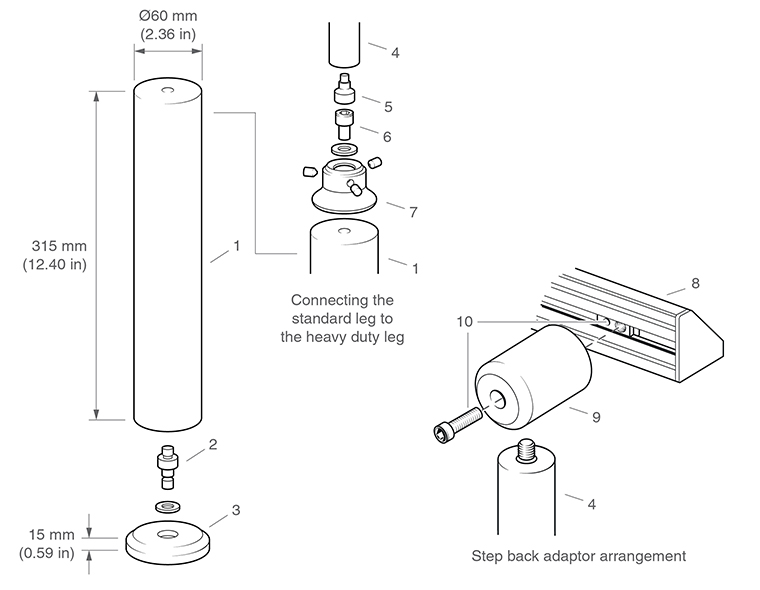

Where an MRS installation has numerous SCP80s containing heavy stylus arrangements, or vertical stylus arrangements exceeding 190 mm, it is recommended that the optional MRS heavy duty leg kits are used to provide additional rigidity / height. These kits can be purchased separately to match the number of legs used on the MRS.

NOTE: The MRS heavy-duty leg kit part number is A-4192-0020 and comprises 1 × heavy duty leg (Ø60 × 350 mm long, 1 × footplate and a selection of double-ended threaded studs).

Installation procedure

NOTE: The MRS heavy-duty leg kit must be used in conjunction with the standard MRS leg assembly. The legs should be mounted using the step back adaptor method.

1. Locate the first footplate (item 3) with a suitable threaded stud on the CMM table having consideration for the required position of the MRS rail that will accommodate all loaded racks within the working volume. Fasten the footplate to the table using the double-ended threaded stud* (item 2).

2. Locate the second footplate (item 3) at the appropriate distance along the chosen CMM axis and follow step 2 above.

3. Screw the heavy duty leg (item 1) to the top of the threaded stud (item 2) and hand-tighten. Repeat for second leg assembly.

4. Place the first MRS foot (item 7) (part of the standard MRS leg assembly) on top of the heavy duty leg (item 1) and secure using the M10 screw (item 6). Repeat for the second leg assembly.

5. Proceed with the remaining construction of the MRS system as described in the pages detailed:

• Aligning the MRS feet to the CMM axis

• Fixing the standard MRS legs to the rail using step back adaptors

• Fixing the standard MRS legs to the MRS foot

* Two sets of double ended threaded studs are provided to suit different CMM table configurations. The thread sizes supplied are M10, M8 and M6. Alternatively, 3/16 " UNC and 5/16 " UNC can be obtained on request from your Renishaw supplier.

Key | Description |

1 | Heavy-duty leg |

2 | Leg to foot adaptor and washer |

3 | Footplate |

4 | Standard MRS leg |

5 | Leg to foot adaptor |

6 | M8 or M10 screw or washer |

7 | MRS foot |

8 | MRS rail |

9 | Step back adaptor |

10 | T-nut and screw |