Navigation

RTP20 system description

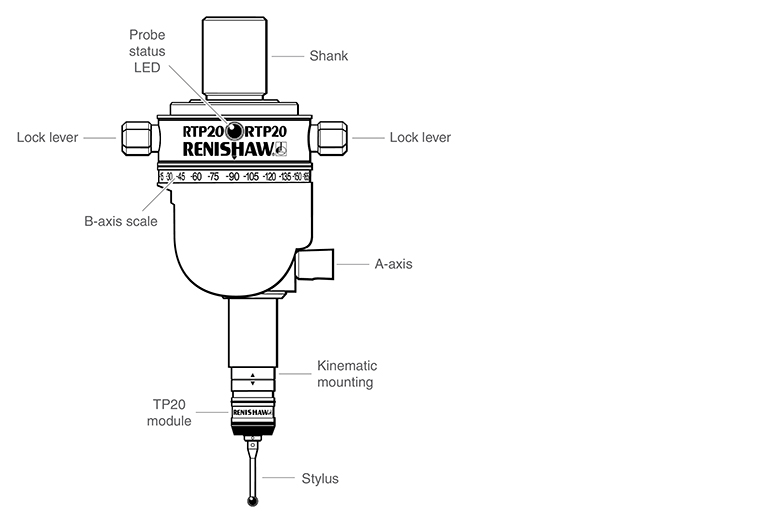

RTP20 is an indexable head that uses the CMM's motion for repeatable repositioning. It offers low-cost ‘motorised' head functionality with an integral TP20 touch-trigger probe.

Automated indexing of the head is realised through an innovative process which uses the motion of a CMM to achieve motorised head style operation. This indexing process comprises of three operations:

- An external locking lever on the probe head is driven against a dedicated sphere mounted to a pole located on the bed of the CMM, thus unlocking the head

- The CMM motion is then used to engage a drive-cup located in the head's A-axis swivel, with the pole-mounted sphere, enabling rotation of the head in the A and B-axes by driving around the pole

- The indexing operation is completed by again using the CMM motion to drive the locking lever against the pole-mounted sphere, thus locking the head

The automated indexing of the RTP20 allows the integral TP20 probe to be moved to 168 repeatable positions in 15-degree increments using both the A and B-axes, requiring a one-time only qualification for each stylus position thus ensuring fast throughput for part inspection. Using the CMM motion to lock and orientate the head together with the MCR20 change rack, which allows repeatable interchange between qualified probe modules, provides a fully automated system.

Electrical connection is via a 5 pin DIN connector.