Lösningar med processtyrning för tillverkningsbranscher

Processtyrning för tillverkning

I mer än 50 år har vi levererat mätningslösningar för tillverkare över hela världen. Vår första produkt revolutionerade automatiserad inspektion på CMM:er. Sedan dess har vi introducerat ett brett spektrum av världsledande teknologier för probning av verktygsmaskiner, maskinkalibrering och optimeringssystem, mätsystem för verkstadsgolvet, system för additiv tillverkning samt lösningar för anslutbarhet till smarta fabrikskoncept.

I våra egna fabriker introducerade vi ett strukturerat koncept med processtyrning som vi kallar vårt Productive Process Pyramid™. Det demonstrerar hur processvariation och detaljavvikelser kan hanteras vid källan. Att förstå har du eliminerar källor till variation och osäkerhet från din bearbetning kan hjälpa dig öka produktionsflödet samt ge dig mindre merarbete och kassationer.

Det är vårt uppdrag att hjälpa våra kunder öka produktiviteten, kapaciteten och effektiviteten på deras tillverkning. Och varierande branscher inom allt från flygindustri till ortopedi, tillämpar framgångsrikt vår teknologi genom hela tillverkningsprocessen.

Läs mer om hur vårt koncept för processtyrning, Productive Process Pyramid, visar hur du kan identifiera och kontrollera källor till variation inom dina metallskärningsprocesser, från inställning och kalibrering av din maskin till inspektioner vid produktionslinjens slut.

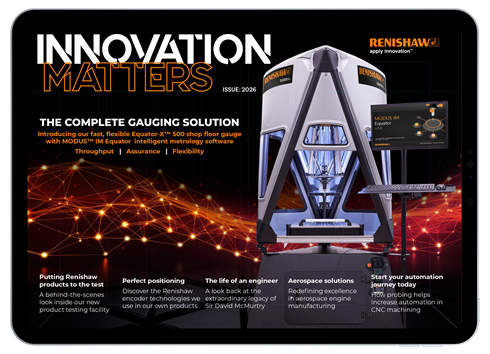

Innovation Matters

För att läsa mer om våra teknologier och deras praktiska tillämpning, ladda ner den senaste utgåvan av vår tidskrift ’Innovation behövs’.

- Den kompletta mätlösningen: Vi introducerar vårt banbrytande nya mätsystem för att kontrollera processerna på verkstadsgolvets tillverkningsprocesser.

- Flygindustri: Utforska Renishaws teknik för högproduktiv tillverkning av flygplansmotorer.

- Automation: Få tillgång till nya nivåer med verktygsmaskinprestanda och börja din automationsresa med probning på maskinen.

- Unik inblick hos Renishaw: Få en unik inblick i de test- och kvalitetssäkringsmetoder som definierar vårt goda rykte.

Även i denna utgåva

Expertutlåtanden, nyheter, fallstudier, intervjuer och produkter i fokus.