Navigation

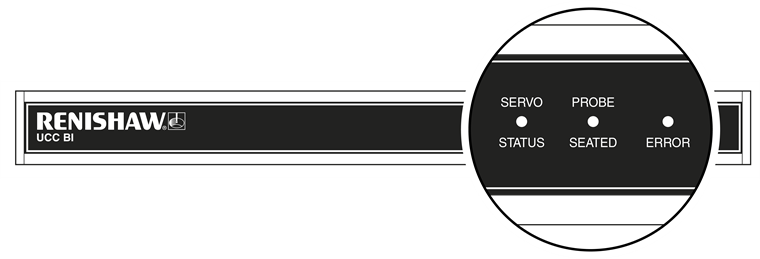

UCC BI introduction

The UCC BI is required for a CMM system which uses brushless motors. The UCC BI provides the interface between the CMM controller and the SPA2-2 (which provides power to the brushless motors).

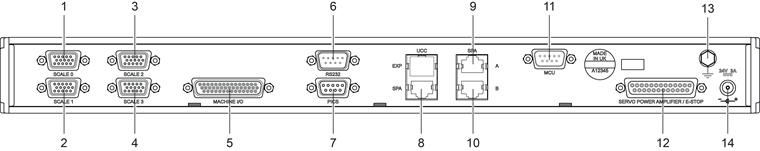

| Key | Description | Key | Description |

|---|---|---|---|

| 1 | Scale 0 interface (15W HDD socket) | 8 | UCC - SPA (RJ45 socket) |

| 2 | Scale 1 interface (15W HDD socket) | 9 | SPA - A (RJ45 socket) |

| 3 | Scale 2 interface (15W HDD socket) | 10 | SPA - B (RJ45 socket) |

| 4 | Scale 3 interface (15W HDD socket) | 11 | MCU (9W D plug) |

| 5 | Machine I/O (44W HDD socket) | 12 | Servo power amplifier / E-STOP (25W D socket) |

| 6 | RS232 (9W D plug) | 13 | Earth terminal |

| 7 | PICS (9W D socket) | 14 | UCC BI power jack (6.3 mm socket) |

NOTE: Please see 'Troubleshooting' section for assistance in diagnosing system faults.

WARNING: The capability to connect the UCC BI to a third party analogue amplifier requires UCCsuite v5.3 or newer.

Features

- Up to four CMM axes can be handled by the UCC BI

- Up to five CMM axes can be handled by a dual UCC BI system.

- The UCC BI can automatically adjust the supply voltage to encoder readheads (to compensate for long scale cables)

- Some 3rd party temperature compensation boxes can be interfaced to the UCC BI using the RS232 interface

- Probe interface (PICS)

- MCU interface

- Supporting incremental and absolute encoders

- CMM machine input / output, including:

- Air solenoid

- Brakes (for each axis)

- Z-axis crash status

- Travel limit warnings (both inner and outer limits for each axis)

- Air status

- 13 un-committed I/O (6 input and 7 output) that can be customised by the user