Navigation

SFP1 legacy probe

Surface finish / surface roughness measurement

- Traditionally measured with hand-held sensors or on a dedicated measuring

machine - REVO-2 SFP1 probe makes surface finish inspection an integral part of your

CMM measurement procedure - Surface finish analysis can form part of a single measurement report

System benefits:

Automatic changing of the SFP1 probe and stylus holders is possible using the standard MRS / MRS2 rack and RCP ports - this enables surface finish measurement to be fully integrated with the standard CMM inspection program

Automatic changing of the SFP1 probe and stylus holders is possible using the standard MRS / MRS2 rack and RCP ports - this enables surface finish measurement to be fully integrated with the standard CMM inspection program- The SFP1 probe takes advantage of the infinite positioning capability of the REVO-2 head

- Sensor calibration involves measuring the surface finish of the surface finish calibration artefact

(SFA) that is mounted on the MRS / MRS2 rack - the calibration software adjusts parameters within

the probe in accordance with the calibrated value for the artefact - The SFP1 includes a passive C-axis that enables surface finish measurements to be made at

all required orientations around a part - the process of changing the C-axis angle is fully

automatic, utilising the B-axis positioning of the REVO-2 head to rotate the SFP1 - The SFCP (C-axis port) is mounted on the MRS / MRS2 rack and features spring-loaded pins to facilitate rotation of the C-axis using the REVO-2 head's B-axis motion

C-axis

The SFP1 has a C-axis that enables surface finish measurements to be made at all required orientations around a part. The process of moving the C-axis is fully automatic utilising both the REVO-2 head B-axis and SFCP. The reorientation routine is handled completely through UCCserver.

Probe characteristics

- SFP1 is a skidded probe type with a 2 μm radius diamond stylus tip - the skid is held against the surface with a controlled force of approximately 0.2 N whilst the stylus tip force is 0.001 N

- The SFS-1 straight and SFS-2 cranked stylus holders have been designed to facilitate access to a wide range of features

- The probe size with a straight stylus holder allows measurement within a 10 mm diameter bore to a depth of 100 mm

- Surface measurement capability: 6.3 µm to 0.05 µm Ra

- Output: Ra, RMS and raw data are returned from UCCserver to the metrology application client software using the I++ DME protocol - the raw data can subsequently be presented to specialist surface analysis software packages for further detailed reporting

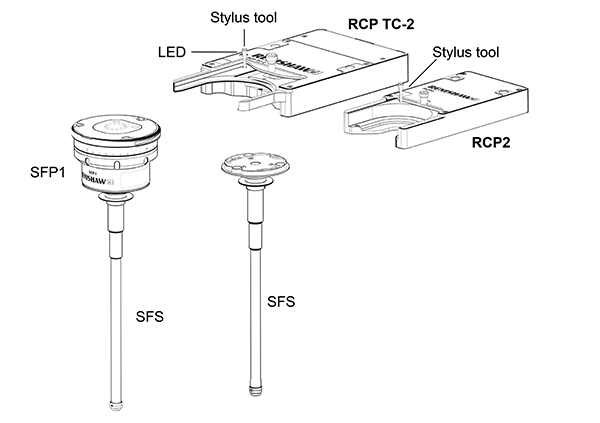

SFP1 and SFS-# changing system

The RCP TC-2 (thermally controlled REVO-2 change port) is used for changing SFP1, whereas the RCP2 (REVO-2 change port) is configured to change SFP1 styli (SFS-1 and SFS-2).

NOTE: The stylus tool is used to keep the port lid open during calibration. It must be removed for normal operation.

SFP1 styli should not be manually fitted to the RCP.

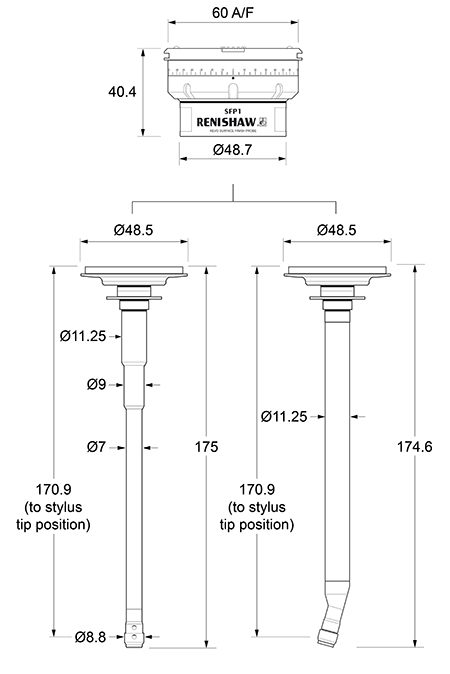

Dimensions

NOTE: Dimensions in mm (in).

Videos

-

SFP1 video - Part scanning and C axis alignment

SFP1 video - Part scanning and C axis alignment

Video showing REVO and SFP1 scanning a part and re-alignment of the C-axis.

-

SFP1 video - Calibration on SFA

SFP1 video - Calibration on SFA

Calibration of REVO and SFP1 on the SFA