Navigation

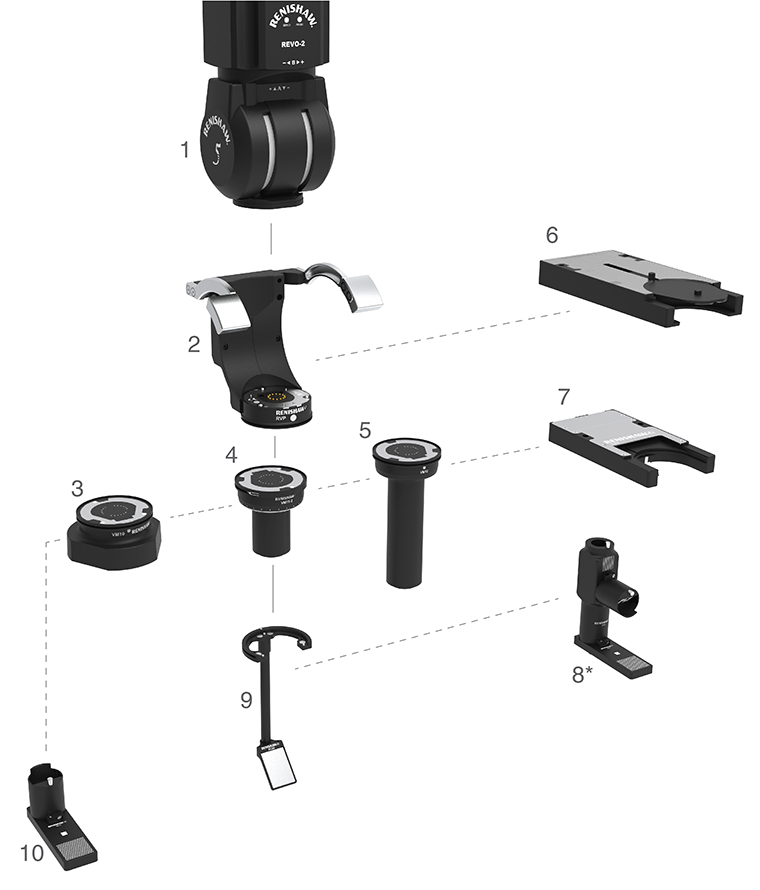

System components overview

Key | Description | Part number |

|---|---|---|

1 | REVO-2 head | A-5759-0001 |

2 | RVP vision probe | A-5378-0080 |

3 | VM10 vision module | A-5378-0082 |

4 | VM11-2 vision module | A-5378-0093 |

5 | VM12 vision module | A-5378-0088 |

6 | VPCP probe change port | A-5378-0081 |

7 | VMCP module change port | A-5378-0083 |

8 | VA90 calibration adaptor | A-5378-0091 |

9 | ACM kit | A-5378-0094 |

10 | VA11 calibration artefact | A-5378-0089 |

* NOTE: VA90 calibration adaptor shown fitted to VA11. The VA90 calibration adaptor (A-5378-0091) does not include the VA11.

RVP probe

RVP is the probe component of the system that houses the sensor and digital signal processor. There are currently two vision modules that attach to the probe body that enable the inspection of a range of size and shape features.

The RVP component of the system is automatically interchangeable with other probe options using the VPCP heated change port that can be fixed to the MRS rack system.

Vision modules

The RVP system features three interchangeable vision modules (VM10, VM11-2 and VM12) which are tailored to provide inspection capability for different applications. The vision modules attach to the probe body using the same style kinematic mount utilised by all the current REVO probes.

VM10 has a wider field of view allowing larger features to be inspected. VM11-2 has a greater stand-off distance which improves accessibility when inspecting complex parts with hard to reach features. VM12 has high magnification for inspection of very small features.

ACM accessory

The ACM is an accessory designed to enhance access for the RVP non-contact vision system. Using a precision, first‑surface mirror, ACM rotates the field of view through 90° allowing vision inspection of bore surfaces and other features previously inaccessible to RVP. ACM is compatible with VM11-2, attaching magnetically to a kinematic ring on the module.

NOTE: ACM uses a first-surface mirror - the reflective coating is on the front surface of the glass and is very delicate. Care must be taken to avoid touching the mirror surface to prevent contamination and damage.

VA11 calibration artefact and VA90 calibration adaptor

The VA11 is a dedicated calibration artefact used to calibrate the target feature size and stand-off distance of the RVP system when using a VM10, VM11-2 or VM12. The VA90 calibration adaptor converts VA11 into a calibration artefact compatible with ACM. The calibration routine for RVP is fully automated through MODUS and UCCsuite.

VPCP and VMCP change ports

There are two new change ports that can be mounted to an MRS rack system to allow the automated changing of all the RVP probe and module components.

The VPCP change port is used to change and house the RVP probe body on the machines rack system. The VMCP change port changes and houses the ACM and vision module components of the RVP system. Both rack ports are temperature controlled to ensure that the housed components are at the correct and most efficient operating temperature.