Navigation

SFP2 system description

SFP2 system

The SFP2 probe system brings automated surface finish (roughness) measurement to CMMs as part of the REVO 5-axis multi-sensor measuring system.

The SFP2 system hardware is comprised of a probe, a module holder, a range of modules and accessories to enable automatic interchange of surface finish modules or between different probe types. Calibration and gain setting artefacts are also available to ensure that the system is performing at its optimum capability at all times.

Specific surface finish analysis software is also required to interpret the data collected by the REVO system.

Because the SFP2 system is used as part of a multi-sensor system, and uses specially designed calibration routines, the location of the stylus tip is known precisely. Surface finish data can therefore be collected from a specific location, even if there is significant variation between nominally identical parts. The surface data, together with its analysis results, can then be stored alongside the part's dimensional data for future reference.

SFP2 system

The SFP2 probe system brings automated surface finish (roughness) measurement to CMMs as part of the REVO 5-axis multi-sensor measuring system.

The SFP2 system hardware is comprised of a probe, a module holder, a range of modules and accessories to enable automatic interchange of surface finish modules or between different probe types. Calibration and gain setting artefacts are also available to ensure that the system is performing at its optimum capability at all times.

Specific surface finish analysis software is also required to interpret the data collected by the REVO system.

Because the SFP2 system is used as part of a multi-sensor system, and uses specially designed calibration routines, the location of the stylus tip is known precisely. Surface finish data can therefore be collected from a specific location, even if there is significant variation between nominally identical parts. The surface data, together with its analysis results, can then be stored alongside the part's dimensional data for future reference.

System components overview

SFP2 probe

The SFP2 probe houses electronics to condition the signals from the transducer within the SFM module so that they can be communicated to the controller via the REVO-2 head. The probe also houses a C-axis motor arrangement with +/-180° rotational ability which complements the A and B axes provided by the REVO-2 head. C-axis rotation is used in combination with the SFM knuckle angle and the tip shape of the SFM to access a large range of parts and part features. The C-axis motion is not synchronised with the head or CMM motion. Care should be taken when programming C-axis rotations within or near to parts under inspection.

SFH holder

The SFH holder fits onto the SFP2 probe via a kinematic magnetic joint. It carries the required surface finish module using a manually adjustable knuckle joint. The holder can be stored in the MRS or MRS2 rack either fitted to an SFP2 probe (in an RCP TC-3 port) or separately in an RCP2 port. In both cases they will have a surface finish module attached whilst in the rack.

There are two holders available; SFH-1 and SFH-2. The SFH-2 is 50 mm longer than SFH-1 and may need to be used for accessing certain features. However, there are usage restrictions associated with SFH-2 the extent of which depend on the SFM module being used. For details of the restrictions, please refer to the module data sheet.

SFM-##

There is a range of surface finish modules which are optimised for specific applications. The module contains the stylus tip, skid and electronics to transduce the 'vertical' motion of the tip as it moves across the surface. The module is supplied as an assembly which is fitted to the knuckle joint on the SFH holder. The SFM is not a user servicable part.

Please refer to your local Renishaw supplier or the Renishaw website for information on the latest range of modules.

MST

The module setting tool is used to assist in setting the knuckle angle between the SFM module and the SFH holder. It clips on to the SFH and enables access to the knuckle joint adjusting screw. It is possible to adjust the angle to within 0.5 degrees of a required angle.

RCP TC-3

The thermally controlled RCP TC-3 port maintains its stored probe at operating temperature. It is compatible with Renishaw's MRS and MRS2 rack systems. It should be used for SFP2 and RSP3-6 probes.

RCP2

The RCP2 enables rapid and repeatable changing of holder / module configurations. It is compatible with Renishaw's MRS and MRS2 rack systems.

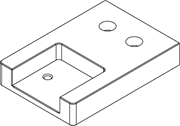

SFA

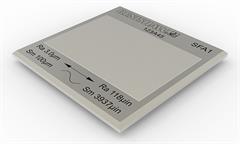

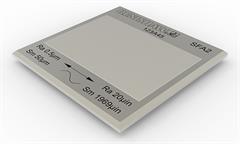

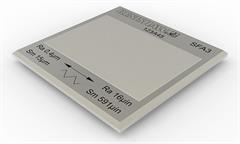

There are three SFA plates, each one supplied with screws for fixing to a single or triple SFAH artefact holder. The SFP2 gain is set using the SFA1 - 3.0 SIN fitted to the appropriate artefact holder accessory. It must be mounted on Renishaw's MRS and MRS2 rack systems.

The module gain can be validated using the SFA2 - 0.5 SIN.

The condition of the 2 µm radius diamond tip can be verified using the SFA3 - 0.4 ST.

| SFA1 - 3.0 SIN | SFA2 - 0.5 SIN | SFA3 - 0.4 ST |

|---|---|---|

|

|

|

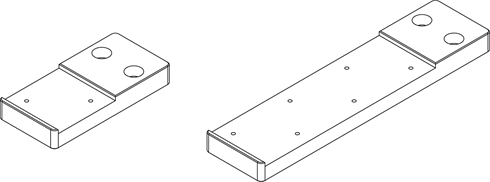

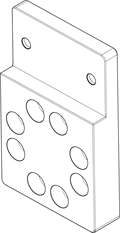

SFAH-#

The SFAH is used to hold the calibration artefact plates. There is an SFAH-1 for holding one plate and SFAH-2 which holds up to three plates. The SFAH holders fix to the rail adaptor or the OFA optical flat artefact.

SFAH-R

The SFAH-R rail adaptor supports the single or triple artefact holding plate and can be fixed to the MRS2 rail or MRS2 leg via the SFAH-M universal mounting plate.

SFAH-M

The SFAH-M is a universal mounting plate for the SFAH artefact holders. It can be fitted to an MRS2 rail or leg and provides 20° adjustment steps for the artefact holders so that the optimum angle can be selected for calibrating the SFM modules.

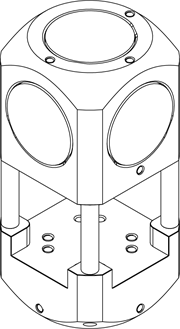

OFA

The OFA optical flat artefact is used as a check on the suitability of a CMM for surface roughness measurement. It comprises six optical flats mounted in the faces of the cube and can also accommodate two SFAH artefact holders. The OFA can be secured to the bed of the CMM where required using the adaptors supplied.

TFP

The TFP tip find probe with a low force module is fitted to the MRS or MRS2 rack. It is used to calibrate the C-axis geometry, knuckle angle and the tip position. Routines for using the TFP are managed as part of an automated calibration routine from UCCserver. The TFP is connected with a PICS cable to an SPA3, UCC BI or UCC AI.

MPS1

The MPS1 is a spacing tool to enable correct spacing of the RCP TC-3 on an MRS2 rail and its adjacent ports.