QuantAM – Additive Manufacturing build preparation software

A dedicated build preparation software tool for Renishaw additive manufacturing (AM) systems.

Take advantage of QuantAM's built-in advanced features, such as TEMPUS™ technology and Swimlanes. These powerful tools enhance functionality and improve printing efficiency.

The software seamlessly integrates into your design process by allowing users to upload 3D CAD models, review and modify part orientation, and then export them in the .renam or .mtt file format required by Renishaw's AM systems.

RenAM 500 series additive manufacturing machines

QuantAM software integrations

We have worked closely with leading providers of AM software to enable compatibility with our RenAM 500 series machines.

This means customers can build on Renishaw systems whilst continuing to use their supported third-party CAD software, thanks to the integration of the QuantAM API.

QuantAM software is integrated with these CAD vendors:

- Autodesk

- Dassault Systèmes

- Dyndrite

- Materialise

- Siemens

Key features

File upload

QuantAM supports CAD import in .catpart, .ctm, .prt, .sab, .sat, .stl, .x_t, .stp, .step, .x_b, .sldprt, and .cli formats for build preparation. You can also import material development data through .csv files.

Orientation

Adjust the orientation and position of parts to optimise quality and maximise build area usage. Consider chamber gas flow and layer direction for more efficient and reliable builds.

Supports generation

Easily add supports to your parts to ensure they print correctly. Support structures can be imported from CAD software. QuantAM also includes automatic support placement to speed up the build preparation.

Laser assignment

Visualise the printing process with the ability to generate slice previews in real time. Additionally zoom in to view laser scan path for each layer.

Advanced features

QuantAM can make the most of the many advanced laser scanning strategies available on the RenAM 500 series system. Innovations such as TEMPUS™ technology and Swimlanes can help increase the processing speed of your parts, as well as improve build quality.

TEMPUS™ technology

QuantAM software utilises Renishaw's TEMPUS technology to enhance productivity in additive manufacturing.

This scanning algorithm allows the laser to fire while the powder recoater moves, which can save up to nine seconds of build time per layer. Over thousands of layers, this can reduce total build times by tens of hours.

Laser parameters can be easily optimised for TEMPUS technology using QuantAM, and integrated directly into the build file.

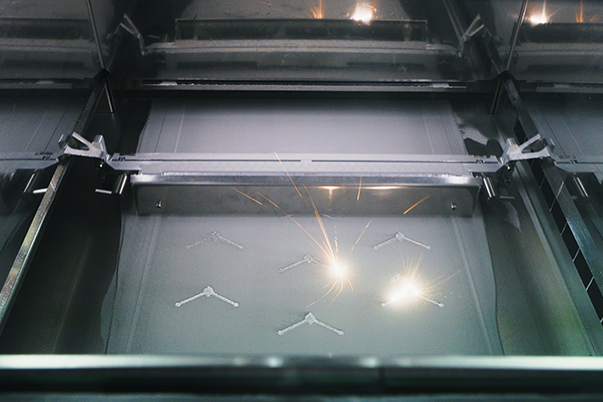

RenAM 500 equipped with TEMPUS technology - lasers are active whilst recoater is in motion

Swimlanes: Visualising the laser scan path with QuantAM

Swimlanes

A notable feature of QuantAM is its efficient multi-laser assignment, which can organise laser paths into distinct 'swimlanes'. This setup allows multiple lasers to operate simultaneously without downstream interference.

This reduces the effect of spatter, smoke and other particles. Distributing the laser load also results in a more consistent print quality and increases print speed.

QuantAM makes it simple to select the Swimlanes strategy when preparing a build file, with the ability to automatically balance laser loads and easily adjust parameters for optimal performance.

Brochure

-

Brochure: QuantAM file preparation software for Renishaw additive manufacturing systems

Brochure: QuantAM file preparation software for Renishaw additive manufacturing systems

Renishaw QuantAM is a dedicated file preparation software tool for Renishaw additive manufacturing (AM) systems. With an intuitive workflow and easy navigation, QuantAM accepts CAD exports in the form of .STL data and allows you to prepare your model for the AM process. QuantAM can also be used as a tool to guide your Design for Additive Manufacturing (DfAM) process, helping you unlock the benefits of additive manufacturing.

Find out more

Discover more about additional Renishaw additive manufacturing software solutions. To request a demo licence or for any queries regarding QuantAM file preparation software, please complete the form below.