Gear manufacturer achieves consistent quality with automated robot cell

Gear and gearbox manufacturer Katsa Oy commissioned Flexmill Oy to design and build a robotised cell to finish-machine and deburr gears ranging in size from 50 mm to 1.5 m diameter.

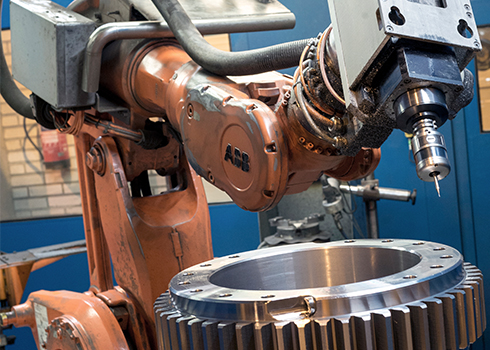

The bespoke, turnkey cell incorporates Renishaw RMP60 probes, mounted on custom-designed tool holders, which an ABB robot uses to collect vital part-location data before finishing and deburring operations commence.

Background

Katsa is a family-owned business specialising in manufacturing, rebuilding and servicing precision gears and gearboxes.

Flexmill is globally renowned for designing and building bespoke, robotised cells to finish machine, deburr and linish precision parts such as turbine blades, gears and aerospace components.

Challenge

Deburring gears manually using grinding wheels can be a variable process, resulting in inconsistent finishes across parts in the same batch. Machine-shop operators have to be very skilled to achieve a quality and consistent finish, but even then, variability from one operator to another is unavoidable.

In addition, manual deburring is a dirty and hazardous job, which few operators at Katsa wanted to undertake. As a consequence, finishing and deburring operations became a bottleneck in the company's manufacturing process, with a knock-on effect often causing significant delays.

Solution

To automate the gear deburring process, Flexmill built a cell incorporating an ABB robot, a Renishaw RMP60 probe and a twin pallet system which allows one gear to be machined whilst another is loaded.

To ensure all excess material on the machined gears is removed automatically by the deburring process, the Flexmill software requires the exact geometrical parameters of the gears and the gear teeth. Some of these parameters are known and available for each of the many different gears made by Katsa.

Those parameters that are not known can be measured using the Renishaw RMP60 probe with radio signal transmission. The ABB robot uses the probe for locating parts during set-up, with the resulting positional data used by the control software to generate a complete, automated deburring cycle – with no manual programming required. Once machined, the RMP60 probe is used post-process to confirm finished dimensions.

The Renishaw RMP60 probe has been working very well and it makes it possible for the Flexmill software to generate a full deburring programme for every one of the gears we manufacture.

Katsa Oy (Finland)

The RMP60 probe is ideally suited to this application due to its robust and reliable frequency hopping spread spectrum (FHSS) protocol. This means that communication between the probe and its receiver remains stable even if, for example, ‘line-of-sight' is lost or if another radio source enters the environment.

“Before we invested in the cell, deburring wasn't a nice job for anybody, so there was always a queue of parts waiting. But now, using the Flexmill robotised system with Renishaw's RMP60 probe, any operator is willing to do the job, so there isn't a queue and the lead time is more consistent and predictable.”

“The Renishaw RMP60 probe has been working very well and it makes it possible for the Flexmill software to generate a full deburring programme for every one of the gears we manufacture.”

“We only need to give some parameters to the control and the robot will use the Renishaw probe to create the programme automatically. The result is that quality is always the same, each and every time we deburr a gear. Also, the task of deburring is now cleaner and safer for our machine shop operators, and that's very important.”

Results

Mr. Sami Niemelainen is the Quality and Development Manager at Katsa: “The reason we invested was not to make the job faster; the reason was for better quality and for better health and safety for the operators. If an operator had a large batch of gears to deburr, the quality of the finishing between the first gear and the last was often inconsistent. Operators needed to be very skilled to deburr consistently well.”

About Flexmill

Flexmill Oy is an international high-tech growth company providing intelligent and adaptive surface finishing solutions for Aerospace, Marine and Energy industries.

For more information, visit: www.flexmill.fi

About Katsa

Katsa Oy designs and manufactures power transmission components and supplies special gear units tailored to customer's demands.

For more information, visit: www.katsa.fi