Renishaw conformal cooling solutions prove a boost to moulding productivity

The use of cores incorporating conformal cooling in the moulds for its plastic casings has allowed Alfred Kärcher GmbH & Co.KG to reduce the cooling time for each part by 55%, giving a huge boost to the company's moulding productivity. The special cores, which were designed by Renishaw, were produced using metal additive manufacturing technology.

Background

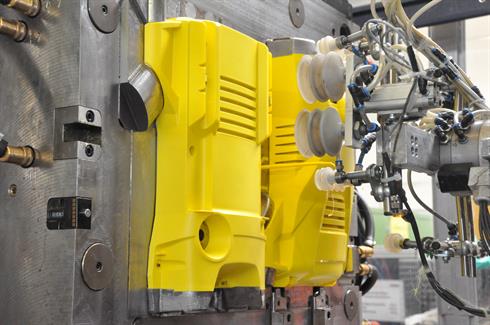

High-pressure washers from Alfred Kärcher GmbH & Co.KG, with their unmistakable bright yellow casings, have become a permanent fixture in many German homes and are growing in international popularity. The devices' power and reliability encourage people to use their “Kärcher” as part of their daily cleaning routine, both inside and outside the home.

To meet the increasing demand from around the world, Kärcher produces its compact washer by the million every year. More than two million K2 basic pressure washers alone leave the Obersontheim factory every year. However, even this level of production is unable to meet the global demand.

Challenge

One of the Kärcher washers' most recognisable features is their bright yellow casings. This was also one of the key bottlenecks in the manufacturing process. For example, the casings for the K2 series washer are produced on six injection moulding machines, each capable of moulding 1,496 casings a day. This was not enough for Kärcher, which has four assembly lines, operating three shifts per day, to give a production capacity of 12,000 assembled and packed K2 high pressure washers each day.

Clearly, one option would be to add more moulding machines. However, Leopold Hoffer, the coordinator for injection moulding at Kärcher's Obersontheim factory, believed that it should be possible to generate more productivity from the existing equipment. “Our aim was to reduce the cycle time from the original 52 seconds to between 40 and 42 seconds,” he explained. He approached Pliezhausen-based LBC Engineering, which was acquired by Renishaw GmbH in May 2013, to work on improving the cooling time in the moulds.

The results were better than expected. Renishaw sold us a complete improvement package, with a holistic consideration and analysis of the mould used to achieve the best results.

Kärcher (Germany)

Solution

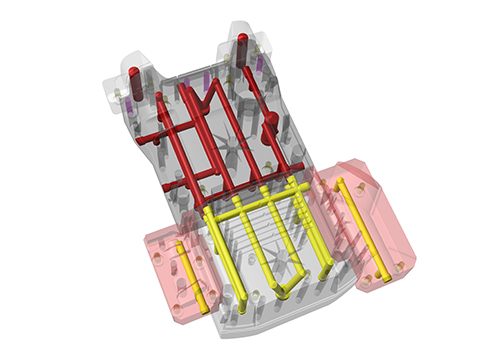

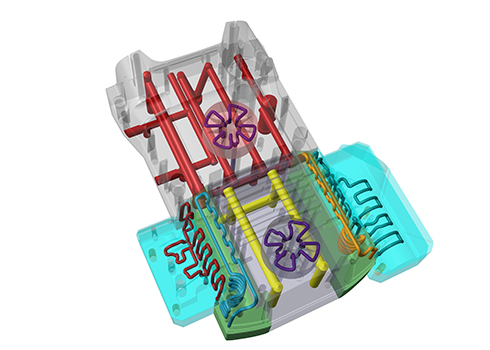

“The first stage of the project was to obtain data for the existing moulds to determine whether Kärcher's goal was feasible,” recalled Carlo Hüsken, who coordinated the project for Renishaw. The existing injection moulding process was mapped with thermographic images provided by Kärcher and simulated using Cadmould® 3D-F simulation software. This revealed that, within the 52 second cycle time, cooling accounted for 22 seconds, with melting at 220°C and de-moulding at 100°C. The mould tool temperature was controlled with water at a temperature of 35°C and a throughput of 10 litres/minute. Hotspots, detected by the thermography, were also modelled, as these areas were responsible for the extended cycle time and needed to be analysed in more detail. With this data, a simulation of 20 cycles was completed, including an analysis of the wall temperature.

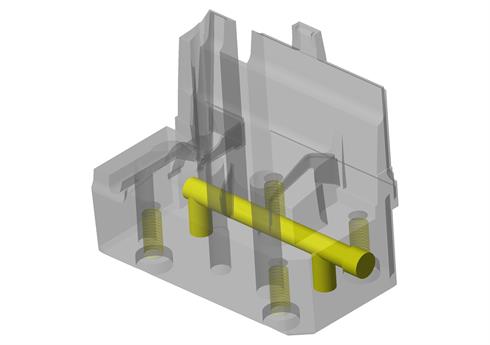

Based on a suggestion from Mr Hüsken, the temperature control on the nozzle side was improved for the second simulation run. The beryllium copper, threaded fitting dome, for the body cover was provided with additional cooling by inserting two conventional cooling channels into the mould plate on the nozzle side.

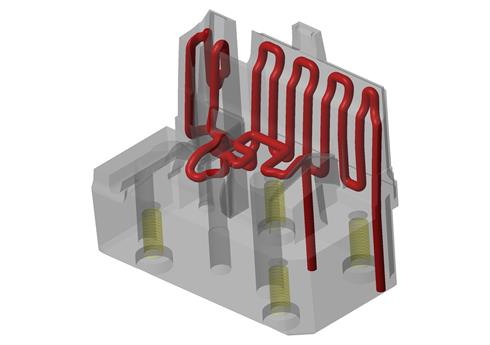

Two simulations were then run to assess potential improvements through the use of conformal cooling. Conventional mould cooling is made up of a network of drilled channels. Drilling the channels limits the geometries that can be produced so, while this is adequate for simpler moulds, it cannot provide the most efficient cooling in more complex examples. Conformal cooling is based on the use of metal additive manufacturing to produce the core of the mould. Additive manufacturing builds the cores in a series of thin layers. The flexibility of this approach means that cooling channels of almost unlimited complexity can be incorporated. Typically, conformal cooling is used to keep the channels at a more equal distance from the moulding, giving more even cooling, or to focus on areas where hot spots are known to exist to give more rapid cooling in those areas.

The simulations showed that practically all of the hotspot areas could be improved through conformal cooling, with the wall temperatures reduced by up to 70°C.

Finally, in one area where there was insufficient space in the mould to incorporate conformal cooling, Kärcher made clever improvements to the product design in order to alleviate the problem.

Based on the results of the simulations, Renishaw presented a comprehensive improvement plan to Kärcher. This showed that conformal cooling could be used to improve the temperature control of the mould hotspots, thereby achieving a more uniform cooling rate and a reduced cooling time. A modified mould design was proposed that would incorporate two additively manufactured cores to provide conformal cooling at the identified hotspots.

Results

The results from the modified mould design were checked by Renishaw, using thermographic images supplied. These confirmed that the wall temperatures could be reduced by 40°C to 70°C. The cooling time was reduced from 22 seconds to 10 seconds, a 55% reduction. Volker Neu, technology and Plastics group leader at Kärcher, produced figures confirming that the new mould design, combined with the re-alignment of some peripheral components (material feed, handling systems, etc.), made it possible to reduce the cycle time from 52 seconds to 37 seconds. As a result, the daily capacity on one machine could be increased from 1,496 to 2,101 castings.

Kärcher then implemented the design changes for the other moulds. The additively manufactured hybrid inserts for these moulds were produced and supplied by Renishaw, with Mr. Hüsken actively supporting the mould-maker during the manufacture of the tooling.

Having been sceptical about the project initially, Mr. Hoffer said, “At the end of the day, the results were better than expected. Renishaw sold us a complete improvement package, with a holistic consideration and analysis of the mould used to achieve the best results.”

Renishaw always bases its client-specific solutions on a combination of technology. “In our case, this meant a mix of conventional cooling technology, project-specific cores produced using additive manufacturing, and vacuum-brazed cores” he added. “From these ingredients, we created the right recipe for the application.”

From this project, Mr. Hoffer has gathered important knowledge and experience. “In future, we will give more attention to cooling in the design phase,” he stated. “Cooling calculations will be an essential stage of each mould design at Kärcher. Using this information, we can then make the decision whether to work with conventional cooling or a conformal cooling solution.”

“Renishaw's support was excellent. For this project, Renishaw was the right choice and the company will also be the right partner when we need close-contour temperature control in the future,” concluded Mr. Hoffer.

Images: Credit Alfred Kärcher GmbH & Co.KG and Mr Gogoll