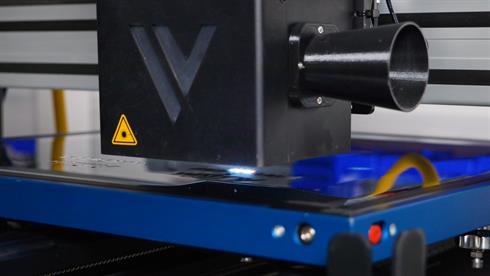

Renishaw encoders deliver laser precision at Watt Laser

Founded in 2020, Watt Laser is a Glasgow-based UK engineering company specialising in high-precision laser systems. The company was born from the vision of a highly experienced laser expert who, after leaving his previous role, wanted to produce innovative surface engineering machines using ultra-short pulse lasers. Starting with just three people, Watt Laser has grown into a dynamic team with a strong emphasis on innovation and agility.

Background

Watt Laser's core mission is to transform high-precision manufacturing by replacing traditional chemical and mechanical processes with cleaner, more efficient laser-based solutions. Its systems are used across sectors including electronics, semiconductor packaging, automotive (including Formula 1), MedTech, and energy. The company's culture is built around empowering young engineers, fostering creativity, and maintaining a startup-like agility even as the company grows.

Central to Watt Laser's success is a commitment to precision. Its machines operate at micron and sub-micron levels, where even the smallest deviation can lead to significant downstream failures. To achieve this level of accuracy and repeatability, Watt Laser relies on Renishaw's encoder technologies, particularly the ATOM™ encoder series and the ADTpro-100 Advanced Diagnostic Tool.

Challenge

Watt Laser's engineering challenges are rooted in the extreme precision required by its customers. Whether manufacturing surface-mount technology (SMT) stencils for circuit boards or welding multi-layer stencil structures, the tolerances are unforgiving.

As Declan Brannagan, Operations Manager at Watt Laser, explains: "In the SMT stencil industry, they cut holes and if that hole is out of position by the width of a human hair, the process falls apart. iPhones don't get made; smartwatches don't get made."

This level of fine precision requires not only high-performance laser systems but also motion control solutions that can eliminate mechanical imperfections such as backlash in ballscrew stages. As Waleed Hafez, Senior Development Engineer at Watt Laser, notes:

"With ballscrew stages, we do get some backlash. With Renishaw encoders, we're able to measure and correct for the backlash in real time."

Another challenge was scalability. Watt Laser needed to streamline its production processes to meet increasing demand without compromising quality. Installation speed and reliability became critical. Fraser Hemming, Senior Product Engineer at Watt Laser, highlights this:

"We needed to get a high-accuracy quality machine to market as quickly as possible."

Additionally, Watt Laser's inspection systems, such as the QC100, required encoder solutions capable of measuring micron-level features.

Declan Brannigan

Operations Manager

Fraser Hemming

Sr. Product Engineer

ATOM optical encoder

Solution

Renishaw ATOM encoders

ATOM encoders provide position measurement at fine resolutions, down to 0.1 micron, for ultra-precise motion control. The compact readhead design allows easy integration into custom laser systems and an integrated set-up LED simplifies installation. ATOM readheads feature filtering optics which provide superior signal stability and reliability, essential for maintaining accuracy during multi-pass laser processing.

Hemming explains, “The resolution is appropriate for all our applications. We've managed to increase our throughput of machines by 30% since we started installing the ATOM systems.” Hafez adds, “The ATOM encoder enables us to have fine control over the motion profiles. Our laser path is incredibly smooth and precise, which enables us to have the best products.”

Renishaw ADTpro-100 Advanced Diagnostic Tool

The ADTpro-100 tool offers various functions to enhance encoder installation and maintenance. A colour touch screen provides plug-and-play functionality with no need for external software. Comprehensive real-time encoder data is immediately available, including encoder serial number, status, signal size, and signal Lissajous plot. The ADTpro-100 is a portable, handheld diagnostic tool ideal for both manufacturing and in-field optimisation or fault-finding.

Hafez describes it as “a useful tool… it makes installation a lot quicker and easier.” He also notes a 30% increase in installation throughput thanks to the ADTpro-100's streamlined set-up process. “It's super easy to use,” Hafez says, “and there's not much training required.”

Elizabeth Shaw

Sr. Business Development Executive

Waleed Hafez

Sr. Development Engineer

Results

The collaboration between Watt Laser and Renishaw has delivered measurable and strategic benefits across multiple areas:

1. Enhanced precision and product quality

Renishaw encoders have enabled Watt Laser to achieve and maintain sub-micron accuracy across its systems. This precision is critical in sectors like electronics and semiconductor packaging, where even the smallest deviation can result in product failure. Hafez emphasises, “We're able to create intricate features. Without the 0.1 micron resolution, we wouldn't be able to have that repeatability.”

2. Increased throughput and efficiency

The ease of installation and reliability of Renishaw encoders have led to a 30% increase in machine build throughput, allowing Watt Laser to meet growing demand without sacrificing quality.

Fraser confirms, “We can install the ATOM encoder quickly. It gives us more throughput for our machines.”

3. Streamlined field service and diagnostics

The ADTpro-100 has empowered Watt Laser's technicians to perform quick diagnostics and installations in the field, reducing downtime and improving customer satisfaction.

“It gives you all the information you need,” says Hafez. “Resolution, type, output – everything's on there.”

4. Strong technical support and collaboration

Responsive support and shared values in innovation have made Renishaw a trusted supplier for Watt Laser. Fraser notes, “Renishaw is at the peak of metrology... we align ourselves with companies that are strong in innovation.”

Hafez adds, “Any technical questions we've had have been answered really quickly and accurately… it gives you peace of mind.”

5. Competitive advantage

By integrating Renishaw's technologies, Watt Laser has positioned itself as a leader in high-precision laser engineering and processing systems. Its ability to offer end-to-end solutions, from machine design to process integration, sets it apart in the market.

In summary

Elizabeth Shaw, Senior Business Development Executive at Watt Laser, explains:

“We're not just manufacturers of machines. We want to fundamentally change high-precision manufacturing… we want to make it greener, faster, and more repeatable.”

Watt Laser's collaboration with Renishaw exemplifies how precision engineering, innovative technology, and strong relationships can drive growth and transformation in advanced manufacturing. Through the integration of ATOM encoders and the ADTpro-100, Watt Laser has enhanced its capabilities, improved efficiency, and delivered exceptional value to its customers.

As Hafez puts it, “When I think of the ATOM encoder, I think of precision, reliability, and ease of use. It's another selling point for our customers that we're using the best of the best.”