Supporting our customers' sustainability goals

We're committed to helping our customers achieve their sustainability goals by developing technologies that reduce waste, improve energy efficiency and extend product life. Working closely with our suppliers and customers, we drive improvements across the value chain, delivering solutions that reduce the impact on the environment whilst boosting performance. These case studies highlight how our innovations are supporting more sustainable manufacturing in practice.

We are engaging with our suppliers

Scaling low-carbon aluminium case study

As part of Renishaw's commitment to achieving Net Zero by 2050, the company has set a strategic target to reduce Scope 3 greenhouse gas (GHG) emissions by 50 percent by 2030. To reach this target, the company is focusing on the most material sources of Scope 3 emissions across its value chain.

Renishaw's analysis identified “purchased goods and services” and “capital goods” as one of the top emitting Scope 3 categories. Within these categories, raw metals - particularly aluminium and steel - are the most carbon-intensive commodities. The project has also strengthened Renishaw's Scope 3 reporting by enabling the collection of primary emissions data from suppliers, improving accuracy and identifying targeted reduction opportunities.

To reduce these upstream emissions while maintaining the high quality of its precision products, Renishaw launched a dedicated project in 2023 led by its Sustainability, Procurement and Materials Science teams. The initiative focused on mapping the aluminium supply chain, identifying emission hotspots and exploring practical pathways to reduce the carbon intensity of purchased aluminium.

By working closely with our suppliers and transitioning to recycled aluminium, we've shown that it's possible to significantly reduce emissions without compromising on quality. This project is just the beginning - we're embedding sustainability into every part of our supply chain and product design to help shape a low-carbon future.

Roz Woodman, Sustainability Value Chain Lead

We are helping customers make more efficient products

Additive Manufacturing (AM) case study

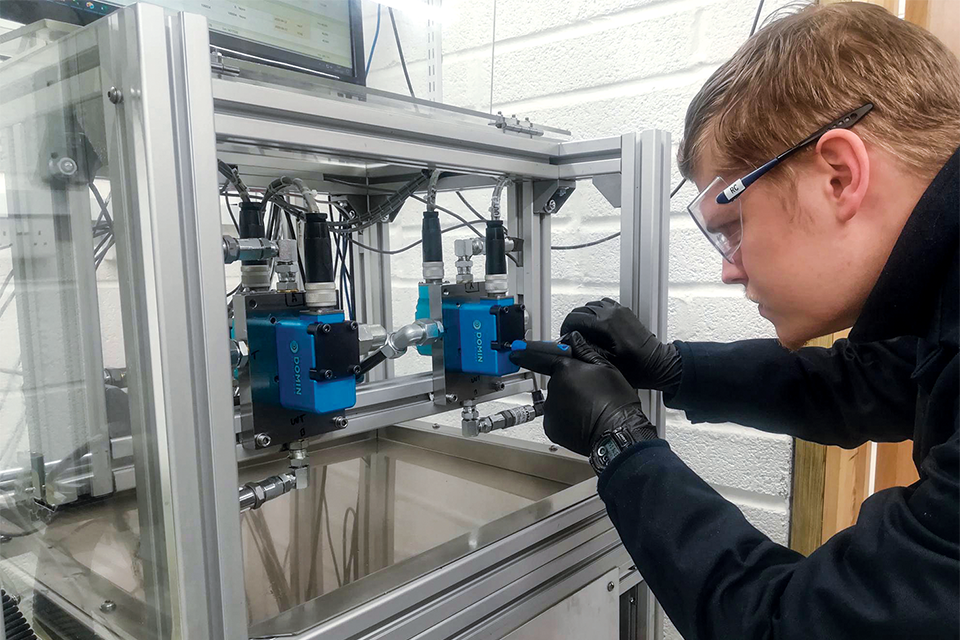

With help from our metal AM technology, UK-based Domin Fluid Power Ltd (Domin) has disrupted the hydraulics industry by redesigning servo valves from first principles. This has achieved a better performing, more sustainable product at a lower price point.

Due to its inherent design freedom, AM allows Domin to build complex parts, free of tooling and with minimal operations and assembly. For example, metal AM provides the ability to design complex geometries with internal features that can significantly enhance efficiency in fluid applications. It produces parts with good strength-to-weight ratio and requires less material than conventional machining, as it only forms metal where required.

Over its lifetime, each of these game-changing valves has the potential to save multiple tonnes of CO2e. Using them we can spearhead the advance of the fluid power industry towards a sustainable future.

Marcus Pont, Chief Executive Officer of Domin Fluid Power Ltd

We are improving battery life

Industrial Metrology case study

Machine tool spindle probing technologies are key to process automation.

Spindle probing allows data to be collected at different points in a manufacturing process to check the condition of parts and tools, and machine performance. It can also process trends resulting from environmental changes and manual interventions. This data can be used to automatically adapt processes to the current situation, to avoid producing a bad part. This helps eliminate waste, re-work and manual intervention. Measurements can also be stored for later analysis and used to help identify longer-term process improvements. CNC machine tools that use our spindle probes with radio signal transmission need a radio machine interface for the machine's controller to receive data from the probe. Our QE series radio transmission probing system acts as a combined radio transceiver and machine interface. It also provides the communication for sensors, offering reliable, automated on-machine tool setting, tool breakage detection, part set-up, and part verification. Updates to the probes' electronics and radio transmission deliver an increase in battery life of up to 400% when used with the RMI-QE interface (compared to the previous generation). This gives an industry-leading battery life of up to five years, based on typical usage.

We are proud of the technological advancements this system delivers, and, with the battery life improvements achieved, equally proud of minimising its environmental impacts.

Steve Petersen, Marketing Manager

We are reducing energy costs

Position Measurement case study

The FORTiS™ encoder series has been designed to improve machine tool performance, productivity and energy consumption.

In terms of sustainability challenges, the largest source of electricity consumption over an enclosed encoder's lifetime is the compressed air that is fed through the encoder to repel contamination, known as air purge. Thanks to our new DuraSeal™ seals, the FORTiS encoder enclosure offers dramatically reduced air consumption, resulting in lower operating costs and greater system longevity. The FORTiS encoder system offers a 70% reduction in compressed air consumption compared to other optical enclosed encoders. As a result, this can reduce the encoder's attributable CO2e emissions and lower the total cost of ownership for the machine user, since less electricity is required to provide the air purge.

Five years of accelerated life testing have enabled the development of our new advanced DuraSeal lip seals. These offer excellent resistance to wear and machine tool lubricants, superior sealing and contamination protection.

Ian Eldred, Principal Mechanical Engineer

INEOS Britannia - Sailing towards a sustainable future with AM

Additive Manufacturing (AM) case study

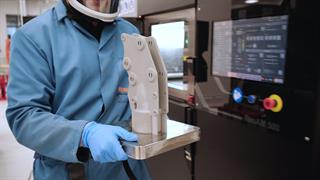

Renishaw has supported the British challenger for the America's Cup since 2016. For the 2024 campaign, Renishaw supplied INEOS Britannia with magnetic encoder solutions and additively manufactured parts, plus expertise in position measurement and Raman spectroscopy.

INEOS Britannia uses additive manufacturing (AM) processes to manufacture some metal parts such as the mainsheet sheave end. AM is a versatile manufacturing technology that allows near-net shape production of a wide variety of complex functional shapes. It offers exciting new design opportunities for combining and optimising parts, potentially reducing tooling and material costs.

In this application, AM can significantly reduce the waste, scrap and embodied carbon* associated with the manufacture of parts, when compared with traditional CNC machining.

INEOS Britannia has used Renishaw's RenAM 500 AM systems to manufacture numerous metal parts on its race and test yachts.