Metrology fixtures for vision systems

Renishaw's fixtures for vision systems and our acrylic base plates allow for back lighting and a clear, clean look at the workpiece from your vision inspection system and multi-sensor machines. Learn how we can support you with improving your machine vision inspection.

Fixturing for vision systems

Complement your vision machine with our range of vision fixturing, Quickload™ corners and non-scratch acrylic base plates.

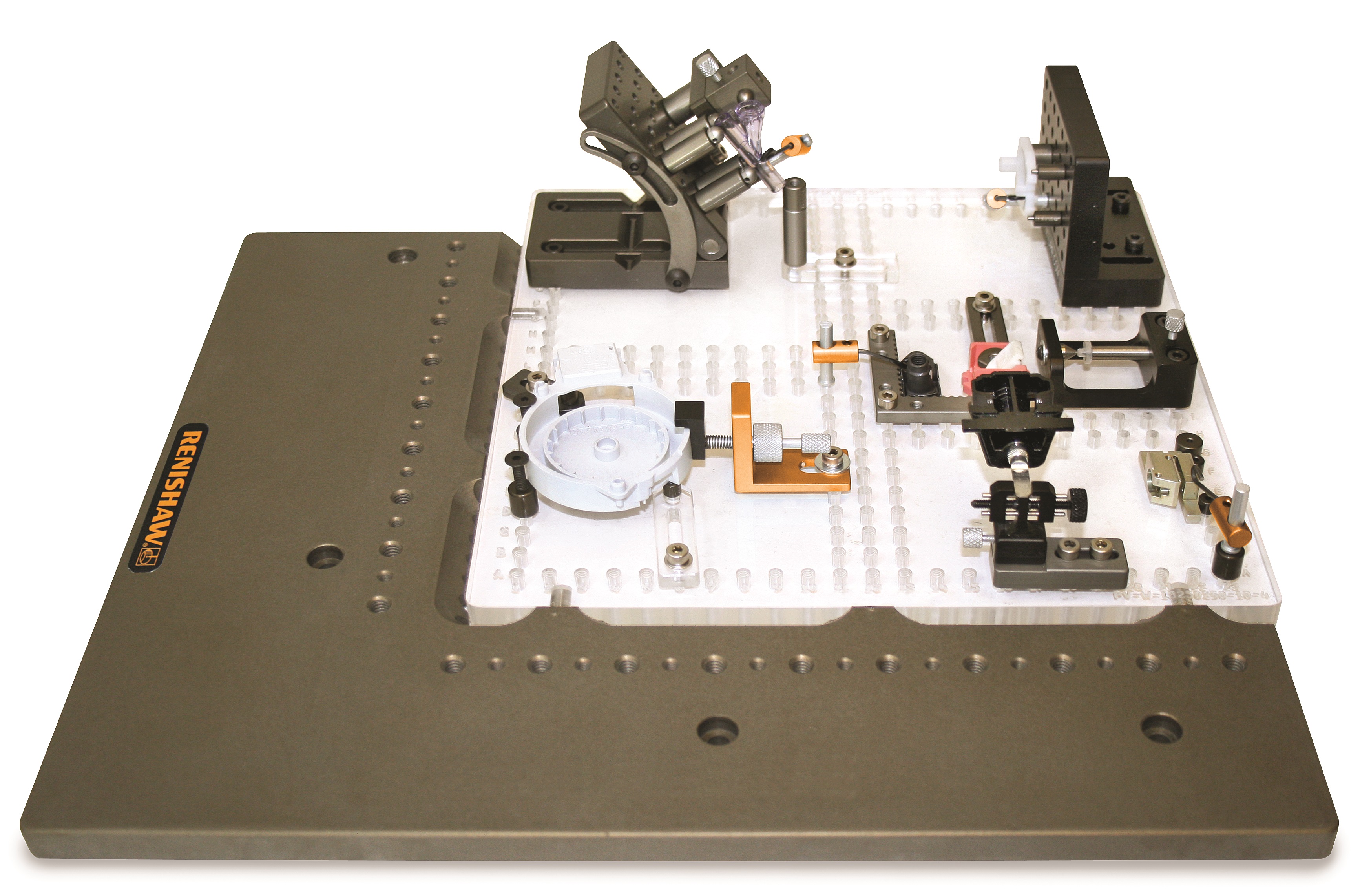

Workpiece fixturing with a clear view

Renishaw vision fixtures for Keyence, Micro-Vu, Mitutoyo, Nikon, Optical Gauging Products and ZEISS systems provide repeatability and secure workpiece holding for any size, shape or type of part for measurement on your vision system. Hold even the smallest of workpieces in a wide variety of ways while maintaining a clear view of the workpiece.

Versatility

Renishaw has a wide selection of modular metrology fixturing components, designed to hold even the smallest of workpieces, allowing for maximum visibility and probe access without obscuring any critical features.

Cut inspection time

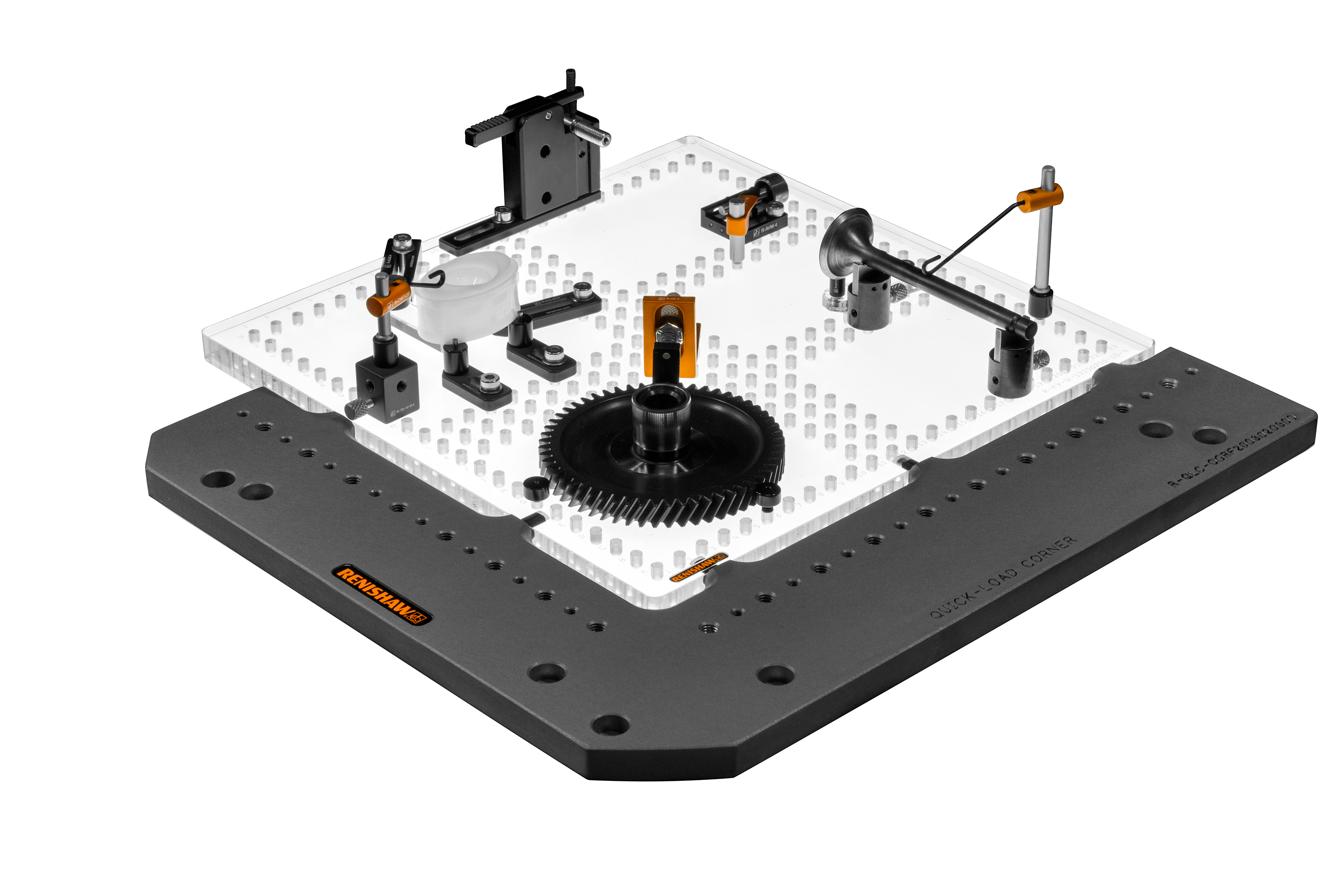

Keep your workpieces set up on multiple plates, switching on and off the machine within seconds. This minimises down time waiting for fixturing to be set up. Both modular and custom plates can be used on Quickload corners, for even greater flexibility.

Made for easy viewing

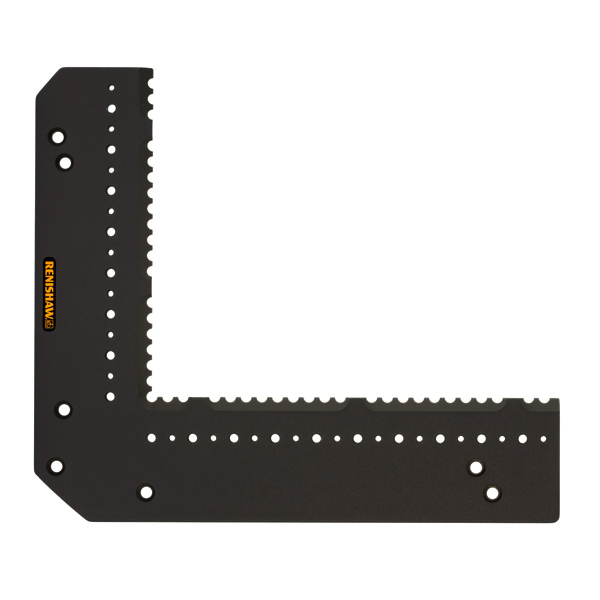

Serrations are present on the edges of the QuickLoad corner. Parts can be inspected easily when mounted directly against these serrations using Renishaw fixture clamping components, which allow complete access around your workpiece.

Reproducible set-ups

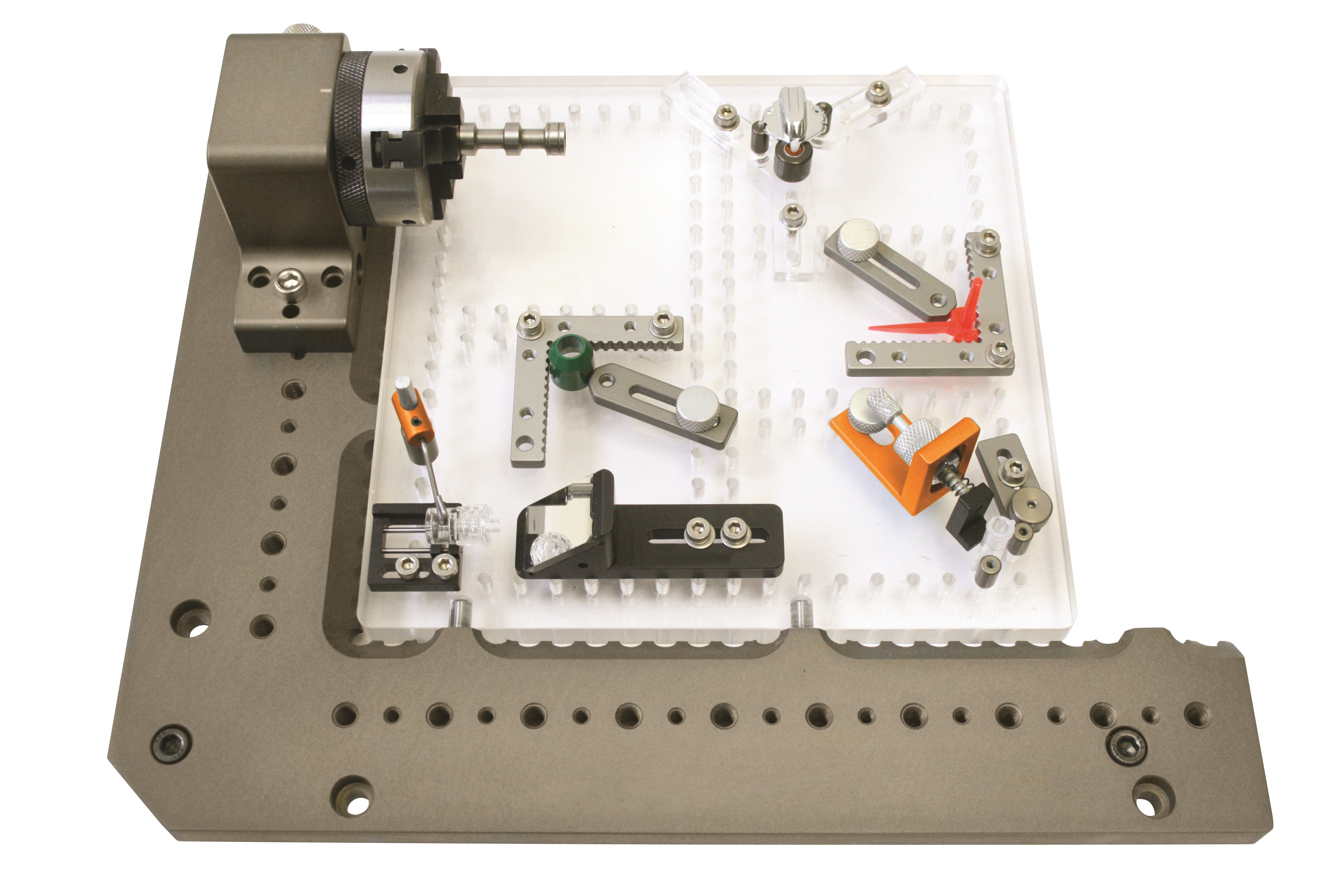

Identical fixturing set-ups are important to ensure the repeatability of inspection by removing variation from the process. Set-ups can be accurately documented and reproduced using our alpha-numerically labelled base plates and labelled fixturing components.

To fixture a workpiece on a vision machine, a Quickload corner, base plate and a fixture kit will be needed. The type of workpieces you are going to fixture, your machine and application, will determine the kit you choose. Additional components may also be required, depending on the nature of the workpiece being fixtured.

How to buy?

Use our Online store to order 24/7. Shop online to benefit from quick delivery of our vision fixturing

Remember our modular and custom fixturing can improve the throughput, reproducibility and accuracy of your inspection process with quick and repeatable fixturing set-ups. Renishaw fixtures can provide a complete solution to your fixturing requirements.

Fixturing made simple with QuickLoad corners

The Renishaw QuickLoad corner fixture is designed to ensure repeatability and provide secure work-holding for any size, shape or type of workpiece for measuring on your vision system. Hold even the smallest of workpieces in a wide variety of ways while maintaining a clear view of the workpiece.

Why use a QuickLoad corner?

- Load and unload within seconds using quick release magnets

- Easy to secure to vision stage using mounting holes ensuring repeatable set-ups

- Ideal for multiple users

- Dedicated sub-plates available to save you time

- Flexibility of both modular and custom plates

- Maximise repeatability and reproducibility when using a QuickLoad corner with labelled components and alpha numeric plates

- Short payback period

Fixture set up

Step 1: Choose a QuickLoad corner

Quickload corners come in multiple form factors, each designed to fit specific models of vision machine. It is designed to fit the lower left-hand corner of your vision stage and the location of its mounting holes. Mounting holes are provided for most major brands of vision systems, to ensure the correct size and proper fit.

The edges of the QuickLoad corner are serrated so that workpieces can also be mounted directly against them and fixed with Renishaw M4, M6 or 1/4-20 fixturing components, for quick and easy inspection.

Step 2: Choose a base plate

Renishaw acrylic base plates contain recessed steel pins that locate precisely onto magnets within the QuickLoad corner. This enables quick, easy and repeatable loading and unloading of plates on to the machine. There are two base plate options to choose from:

- Multi-hole: which offers greater flexibility to set up and check as many workpieces as possible at one time with a clear area in the centre of the plate.

- Multi-window: with more windows for the clearest view of small workpieces.

Step 3: Choose a component set

Renishaw vision fixtures can be purchased in preconfigured kits. A kit consists of a set of components designed to hold small intricate workpieces, ferrous or non-ferrous.

Our vision component sets come in a convenient M4 thread size, ensuring compatibility with a wide range of applications.

Step 4: Choose additional components

Additional vision components can be purchased separately and used alongside the preconfigured component set. Fixturing components are easily adjustable and designed to hold components firmly with the minimum necessary force to avoid damage or distortion. The wide range of components available offers flexibility when setting up a fixture to ensure a clear probe path for inspection.

Not found what you are looking for?

We can provide custom solutions for your vision set-up including custom QuickLoad™ corners or interchangeable vision fixtures.