Equator™ gauging system

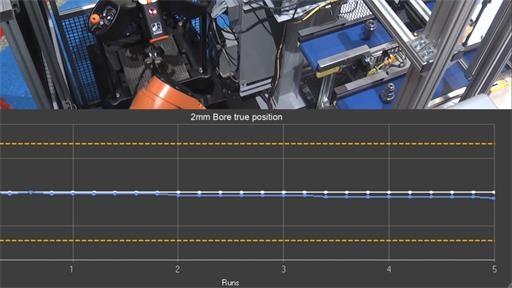

The Equator gauging system enables process control by delivering highly repeatable, thermally insensitive, versatile and reprogrammable gauging to the shop floor.

Shop floor gauging

To control manufacturing processes on the shop floor, gauges have been used for decades, for example sets of callipers, go / no-go gauges or bore gauges. With advances in manufacturing, the need for new process control methods is increasing.

The Equator system is a flexible gauge, designed to provide speed, repeatability and ease of use for manual or automated applications, which is why hundreds of manufacturers worldwide are replacing their current gauging method with Equator systems.

Process control with Equator™ the versatile gauge™

Find out more about the benefits of flexible shop floor process control with Equator systems:

- Reduces scrap

- Reduces bottlenecks

- Low cost of ownership

- Easily automated

- Thermally insensitive

- Versatile and re-programmable