Industrial robot calibration and maintenance solutions

Overcome the major challenges of industrial automation

Industrial robots are essential to the automated manufacturing industry. Completing tasks which would otherwise be dull, dirty, or dangerous for humans. Improving productivity and worker wellbeing.

However, the full potential of an industrial robot is difficult to achieve. The way we currently set up and deploy robot cells is often laborious, inefficient, and inaccurate. And once a robot is ready to operate, there are few reliable ways to track its performance over time. Leading to unexpected mechanical failures and costly downtime.

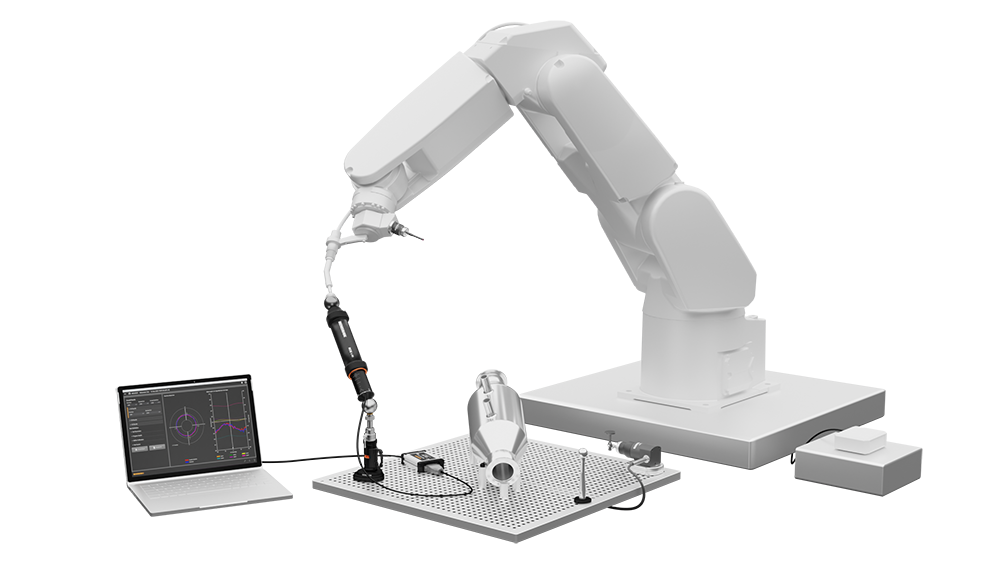

The Renishaw RCS product series offers two industrial robot calibration solutions: a portable 'toolkit' of ballbars for infield robot diagnostics, and permanently installed robot-mounted probes for continuous operational efficiency.

RCS portable ballbar toolkits for robot set up and health checks

The RCS L-90 is a linear ballbar system for faster robot deployment and increased system accuracy. Set accurate tool and part frames, and run tests on path performance and repeatability with this single 90 mm ballbar.

The RCS T-90 is a tri-ballbar system for advanced robot diagnostics. Master your robot on-site and recover easily, without re-teaching programs. Purchased in conjunction with RCS L-90 to diagnose problems from the root cause.

RCS P-series for permanent in-process robot monitoring

Automatically locate tool and part frames in six degrees of freedom (6DOF), and autonomously perform recovery routines with ease.

Including hard-wired, optical, and radio probe which are compatible with a range of robot manufacturers.

Understand our RCS probing solutions

RCS Software Suite

The RCS Software Suite completes our range of RCS products. Conduct ballbar system tests and capture data. Create program templates for robot probing routines to set tool and part frames with reliable accuracy. Follow step-by-step instructions to assess robot performance.

Unlock the full potential of robotic automation

Set up

Master your new or recently relocated robot on the shop floor to ensure accuracy from the start. Set up robot cells with speed, consistency, and traceability.

Monitor

Track path performance, repeatability, and backlash over time. Diagnose any joint offset issues to prevent the need for maintenance and proactively look after your robot health.

Recover

Run automated robot recovery routines with a single button press. Remove the need to re-teach cells with the cell auto-recovery program, getting you back on line within minutes.

[Renishaw demonstrated] the capabilities of the RCS T-90 on site, and by 2pm that day we had affected change in our program, which - without exaggeration - took 90 arc points to complete a circle, down to five points. This represents an immeasurable quality of life improvement for TMF and we can't wait to apply the same improvement to our 15 other weld robots.

TMF Center (USA)

Transform robot commissioning and service processes

Increase productivity

Locate and define tool centre points (TCPs) and part frames with high levels of accuracy. Improving the repeatability of your robot and positively affecting productivity.

Increase uptime

Regularly test your robot's performance to identify issues early. Allowing you to schedule repairs before mechanical failures cause unplanned downtime.

Increase performance

Capture critical diagnostic information and monitor your robot's health. With easy to follow software guides for those new to metrology.

Designed for the automation industry

The RCS product series is built for engineers and production managers looking for the highest level of accuracy, reliability, and efficiency from their robots.

The Renishaw RCS L-90 ballbar and RCS T-90 tri-ballbar enable robot integrators and service managers to provide industry-leading support levels. With the ability to perform robot health checks, and precise set up and recovery services.

Our RCS probing solutions provide manufacturing business owners and automation operators with a consistent and reliable performance from their robots each and every day. Resulting in fewer collisions, reduced downtime, and accurate repeatability.

Support for robot calibration and maintenance products

Learn how to use industrial robot calibration and maintenance products with downloadable guides. Watch video tutorials on installing products and using our accompanying software package.

White paper: Advancing robotic automation

Discover cutting-edge techniques and best practices to enhance precision, reduce errors, and optimise performance in high-stakes environments. Whether you're looking to improve your current systems or planning new installations, this white paper provides invaluable insights and practical solutions to achieve unparalleled accuracy in your robotic applications. Don't miss out on this essential guide to staying ahead in the competitive world of industrial automation.

Contact our sales team today

Complete the form below to find out more information and speak to an expert.