Navigation

SFM-C2 legacy module

Enhanced access and inspection capability for integrated surface finish measurement

Features

Features

The C-series of modules have the ability to locate the stylus in small diameter bores without significant degradation in performance. The skid and stylus are inline so that both travel along the axis of the bore.

Typical applications

Automotive engine valve guide ways.

NOTE: Not compatible with SFH-2.

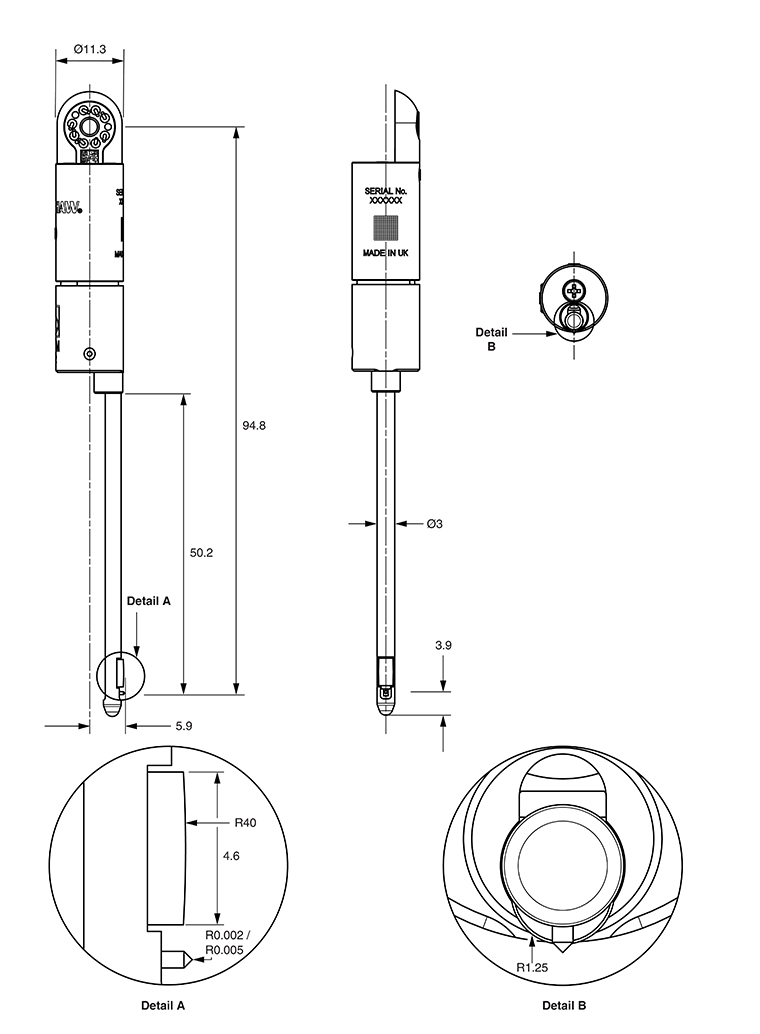

Diamond tip radius (μm) | 2 or 5 |

Surface finish measurement range (μm) 2 μm modules 5 μm modules | 6.3 to 0.05 Ra 6.3 to 0.10 Ra |

Typical surface finish accuracy (of nominal Ra) * | ±(10% + 35 nm) |

Skid / stylus arrangement | In-line (stylus lagging skid) |

Skid material | Tungsten carbide |

Nominal stylus tip protrusion beyond skid (mm) | 0.37 |

Minimum feature access (mm) | Ø5 × 50 |

Skid length / radius (mm) | 4.6 / 40 |

Skid width / radius (mm) | 2.5 / 1.25 |

Skid contact force (N) | 0.15 |

Stylus contact force (N) | 0.003 |

SFM / SFH knuckle adjustment range | ±90° |

Weight (g) | 12 |

Resolution (nm) | 1 |

Measurement speed (mm/s) | Up to 1 |

Stylus holder compatibility | SFH-1 only |

Lateral scanning capability | No |