Navigation

OTP6M legacy probe

The OTP6M optical trigger probe system utilises a visible laser spot (Class 2) to provide a non-contact inspection solution for use on co-ordinate measuring machines (CMMs).

The system comprises a Wolf & Beck Laser Probe (OTP6M), which operates using the optical triangulation principle, and a Renishaw interface (OPI 6).

The system can be used to measure pliable or delicate materials as the sensing beam causes no distortion of the surface. It is easily retrofittable to standard touch-trigger probe applications.

It provides repeatable Z-axis measurements and has edge-triggering capability.

The OTP6M probe is supplied with a Renishaw autojoint which enables autochanging using the PEM1 extension bar and the autochange rack (ACR1). It is compatible with PH6M and PH10M probe heads.

The OPI 6 interface enables straightforward integration of the system onto a CMM. It can be used alone to control standard touch-trigger probes and the OTP6M probe, or in conjunction with the appropriate interface for another multi-wired probe.

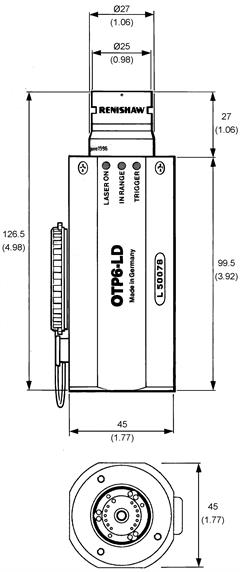

Dimensions

Z-axis repeatability (2σ) | 2 μm* |

|---|---|

1D Measurement accuracy (band width) | ±25 μm** |

Stand-off distance | 36 mm |

Inclined angles | 60°* |

Operating range (nominal value depending on target reflectivity) | ±4 mm |

Spot diameter (full width, half maximum) | 50 μm × 70 μm |

Power supply | Universal: 85 V to 264 V; 47 Hz to 66 Hz |

Power connector | IEC 320 |

Measuring frequency | 20 kHz |

Probing speed | 0.5 mm/s to 50 mm/s |

Wavelength | 680 nm visible red |

Average power | 0.5 mW |

Trigger output | SSR / PICS |

* Figure recorded from a lapped steel target (Ra = 0.34 μm)

** Figure recorded from a diffusing datum sphere (supplied)