Elements of a CMM system

RESOLUTE™ encoders also offer a wide range of rotary (angle) scale diameters providing greater flexibility in product design.

SOLPOWER (Taiwan)

VIONiC™ encoder series

The VIONiC encoder series is Renishaw's highest performing incremental optical encoder. VIONiC encoders provide direct digital position feedback with superior metrology, high reliability, intuitive auto-calibration and a super-compact form factor.

Encoder scales for CMMs

Substrate mastered scales offer a range of benefits for precision CMMs with low CTE / high thermal mass substrates. An alternative encoder scale solution is Renishaw's floating RTL stainless steel tape scales, which can be mounted with the FASTRACK™ scale carrier system, providing easy installation with no fixing holes required and also allowing scale to be quickly replaced, even where access is limited, thus reducing machine downtime.

XM-600 multi-axis calibrator

The XM-600 multi-axis calibrator has been designed with additional functionality allowing it to communicate directly with Renishaw's UCC controllers. Using technology developed for the XM-60 multi-axis calibrator, XM-600 simultaneously measures all six degrees of freedom within a single measurement. This provides the ability to easily create an accurate error map for each linear axis of your CMM.

XM-600 maintains the same compatibility with CARTO as XM-60, making it the ideal calibration solution for any manufacturing facility that utilises both machine tools and CMMs.

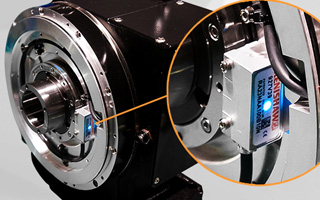

RESOLUTE™ True Absolute Encoder System

For CMM applications that require an absolute encoder system, the RESOLUTE encoder series offers superior absolute position feedback at fine resolutions and with ultra low Sub-Divisional Error and jitter.

Powerful metrology software

MODUS metrology software provides a powerful platform for 5-axis measurement. A configurable user interface allows programs to be developed offline, drawing geometry, embedded dimensions and tolerance data from CAD, with full simulation and collision detection. The software includes certified algorithms for feature measurement, feature construction and part alignment.

Programs can be created offline directly from CAD with on-screen probe path verification. The CMM environment, the fixture and the location of the part on the machine can all be defined, enabling full simulation and crash detection of 5‑axis measurement programs. This minimises CMM down-time as programs arrive at the machine ready to run, with little or no prove-out time required.

Controllers

Renishaw's range of UCC universal CMM controllers provide precise control of the motion of the machine, interfacing to all Renishaw CMM sensors, and communications with the metrology software. Renishaw's UCC flexible controllers provide advanced touch-trigger and scanning algorithms, which allow fast, accurate, adaptive part measurement.