Additively manufactured styli

Manufacturing complex parts calls for custom solutions using additively manufactured styli

Why use AM for custom styli?

Metal additive manufacturing (AM) is a flexible and powerful technology that can be used to create components and parts which cannot be made using traditional manufacturing methods.

These can include complex shapes with internal structures and latticework that are both light and strong, enabling repeatable metrology.

The high degree of flexibility in design means additively manufactured styli can be created and customised for almost any application.

Contact us

Our custom design service for AM styli uses intricate, complex geometry that offers advantages over traditional styli. This can meet design challenges for both new parts and existing ones.

Rapid, custom styli design service

Renishaw manufactures your custom styli in-house and offers a comprehensive custom design service to meet all your metrology requirements. Our custom design service ensures short lead-times; meaning your production does not need to wait.

Contact us to find out more about our custom design service for both traditional and AM styli.

The Renishaw styli range is comprehensive. Please refer to our precision styli for metrology page for more information.

Design freedom

Design parts for their end use, not for inspection. AM styli allow access to features that cannot be reached with traditional styli, so parts will no longer have to be designed for metrology access.

Specially-designed lattice structures and tubular shapes reduce total mass whilst maintaining structural integrity, thereby enabling maximum size to weight ratios. Female threads (M2/M3/M4/M5) can be included to allow the fitment of any additional stylus from Renishaws extensive range of standard styli.

High accuracy metrology

Laser powder bed fusion can create strong, lightweight structures that enable repeatable and accurate metrology results.

Using AM technology, styli are manufactured using the minimum number of parts – and therefore joints – required, significantly improving robustness.

Each stylus is designed to ensure optimum weight, balance and stiffness.

Custom design

All AM styli are designed and produced in house by Renishaw, ensuring short lead times and high standards of quality.

Our expertise allows us to develop a product that satisfies customer demand for accuracy, piece part inspection, delivery and cost. All of these aspects are considered within the design of a custom stylus, ensuring that the solution incorporates the ideal choice of ball and stem materials, and optimises probe performance for your particular application.

Greater design freedom, greater inspection access

Custom styli for metrology applications provide more measurement options than ever before; AM offers the opportunity to produce complex shapes to enable the inspection of previously inaccessible features. AM styli are designed to heighten the capability of the REVO® 5-axis CMM multi-sensor platform, providing increased flexibility when accessing component features.

Combining the flexible technologies of AM and the REVO multi-sensor platform allows manufacturers to have greater freedom in part design. Parts that previously had to be designed to allow inspection access by traditional styli, can now be designed without such metrology restrictions.

Complex geometry to help access all areas

AM styli can be made with intricate, complex geometry that offers advantages over traditional styli and can meet design challenges for both new parts and existing ones.

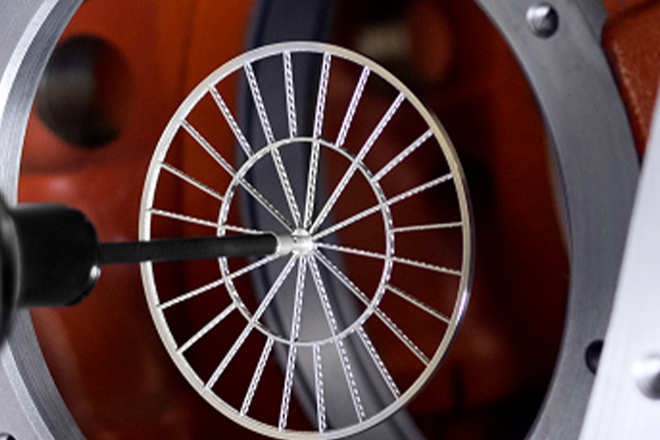

Disc styli are a solution for measuring large features on components, but designing them has been problematic in the past. The discs could only be manufactured in ceramic, which limited the sizes it was possible to produce. A custom AM stylus can provide a stiff and lightweight structure that can be manufactured to a larger diameter than a ceramic styli. A 100 mm titanium disc, with ground outer surface, designed and made by Renishaw, weighs just 13 grams. It provides a 70% reduction in weight compared with a conventional disc stylus of this size.

Featured case study

Linex Manufacturing overcomes inspection challenges using an additively manufactured custom stylus.

Read the case study to find out moreAdditional reading

Discover the benefits of using additive manufacturing (AM) to produce styli and how we can help with your custom styli requirements.