Bespoke bike maker harnesses additive manufacturing

Maintaining the consistency and quality of hand-made titanium bicycle components isn't easy, it takes consummate skill, care and time. Angel Cycle Works challenged Optimus3D to provide a metal additive manufacturing (AM) solution that would produce a chainstay bracket component in a small series quantity to a perfectly uniform quality standard.

Background

Optimus3D provides a complete additive manufacturing service to businesses in a broad range of sectors, including aerospace, automotive, general industrial and medical. It offers an end-to-end solution, comprising component design, prototype and volume production, post-processing and metrology.

Headquartered on the Álava Technology Park in Vitoria-Gasteiz, Northern Spain, the company serves international and local clients, bringing them access to the latest generation of 3D printing machines and software. Its expertise in additive manufacturing enables reductions in component complexity, weight and cost, and increases in component quality and reliability.

Spanish firm Angel Cycle Works is an internationally-renowned bike frame builder and component maker. Hand-making bespoke frames and components in titanium, it is operating at the cutting edge of bicycle technology, producing high performance bikes for road, gravel, mountain and cyclo-cross environments.

Producing a high-quality, high-strength component that relied primarily on hand-welding and small series production, Angel Cycle Works was keen to investigate the use of additive manufacturing as an alternative and approached Optimus3D for a solution.

Pablo Capellan, the Project Leader at Optimus 3D said, “Our expertise in metal additive manufacturing is due in no small measure to our in-depth knowledge of manufacturing and reverse engineering. It means we can more readily adapt a client's requirements to the 3D printing process, making full use of the complete spectrum of AM's capabilities.”

3D printed titanium chainstay bracket component printed on RenAM 500S system

Our thinking was quite simple. By manufacturing the component horizontally, we could minimise the time spent producing the specific batch and help meet Angel Cycle Works budget target. It also meant we were better able to measure and handle deformation, as the chainstay bracket is long and thin, measuring 35 mm x 20 mm x 115 mm.

Optimus3D (Spain)

Comparison of a hand-welded chainstay bracket and metal 3D printed component

Comparison of a hand-welded chainstay bracket and metal 3D printed component

Challenge

“The challenge for Angel Cycle Works in manufacturing the titanium chainstay bracket component by hand fundamentally relates to the source metal itself. It simply isn't the easiest of materials to work with. Particularly when hand-welding, deformations in the component's integrity can occur, and staying perfectly true to a three-dimensional CAD model can be really very hard.”

Capellan continued, “That said, even when it comes to the alternative additive manufacturing process, whether it's building a component by melting metal either in layers or by deposition along a path, titanium can still present challenges.”

In order to produce the component in volume, maximising the productivity of the additive manufacturing process was a further key criteria for Optimus3D. Not only did it need to guarantee the complete accuracy and reliability of the component, it also needed to ensure that each build volume was yielding the maximum number of components, to make the process as cost-effective as possible.

Highlighted inside of the orange rectangle, shows the location of the 3D printed titanium chainstay bracket

Solution

Optimus3D proposed the use of its Renishaw RenAM 500S single laser additive manufacturing system. Specifically designed for building metal components in a production environment using powder bed fusion (also called laser melting), it has a generous build volume measuring 250 mm x 250 mm x 350 mm.

Importantly for the Angel Cycle Works bicycle component, the Renishaw system's class-leading inert manufacturing atmosphere (a vacuum filled with high purity argon gas) ensures a very high quality build environment for all qualified metals including titanium Ti6AI4V, the metal powder to be used in this case.

Considering the component's structure and dimensions, building-up in a vertical orientation was the obvious, and generally optimal, first choice. However, recognising the potential deformation issue and the need to maximise productivity, Optimus3D chose to build-up in the horizontal orientation.

Capellan explained, Our thinking was quite simple. By manufacturing the component horizontally, we could minimise the time spent producing the specific batch and help meet Angel Cycle Works budget target. It also meant we were better able to measure and handle deformation, as the chainstay bracket is long and thin, measuring 35 mm x 20 mm x 115 mm.

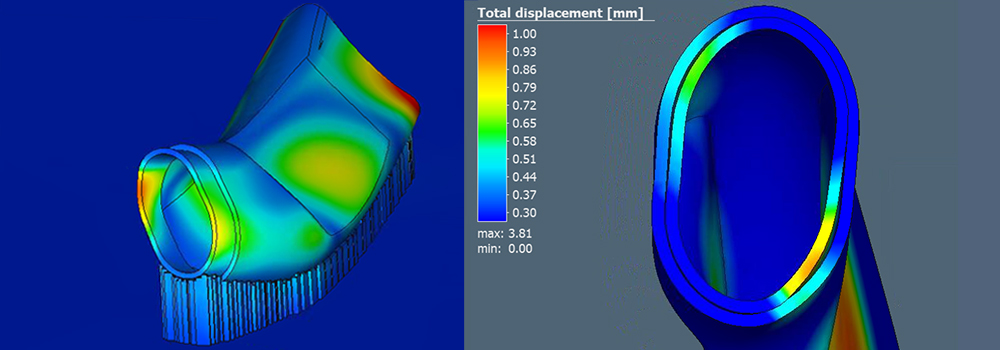

As expected, manufacturing the component horizontally direct from the CAD file yielded an unacceptable 0.375 mm distortion in the most vulnerable area. To remove this error, we teamed up with Renishaw engineers to arrive at an elegant solution that was based on finite element simulation.

Alex Garcia, Renishaw Application Engineer, explained, Using third party Simufact Additive software, we were able to perfectly simulate the powder bed fusion process of the RenAM 500S system. What this then enabled us to do was to determine a precise compensation factor that could be used to accurately 'pre-distort' the component design.

Analysis of the additively manufactured titanium chainstay bracket using Simufact software

Analysis of the additively manufactured titanium chainstay bracket using Simufact software

Results

Using metal additive manufacturing, Angel Cycle Works is able to produce its previously hand-made titanium bicycle chainstay bracket component to a guaranteed high level of consistency, with improved weight and strength characteristics, and in quantities that are better able to meet dynamic customer demand.

While perhaps counter-intuitive to much common thinking, Optimus3D's decision to build-up components horizontally and employ simulation software to adjust the design for manufacture has seen worst case deformation reduced from 0.375 mm to 0.086 mm, well within the component's 100 µm tolerance.

This innovative metal additive manufacturing solution means that each build volume on the RenAM 500S system is able to 3D print as many as 50 identical components at a time and on a very short leadtime. Component cost has been dramatically reduced as a result and supply chain operations streamlined.

Renishaw's RenAM 500S system at the Optimus3D headquarters on the Álava Technology Park in Northern Spain