Enhanced access capability for the REVO® 5-axis measurement system and new functionality for MODUS™ CMM metrology software at EMO 2019

2 July 2019

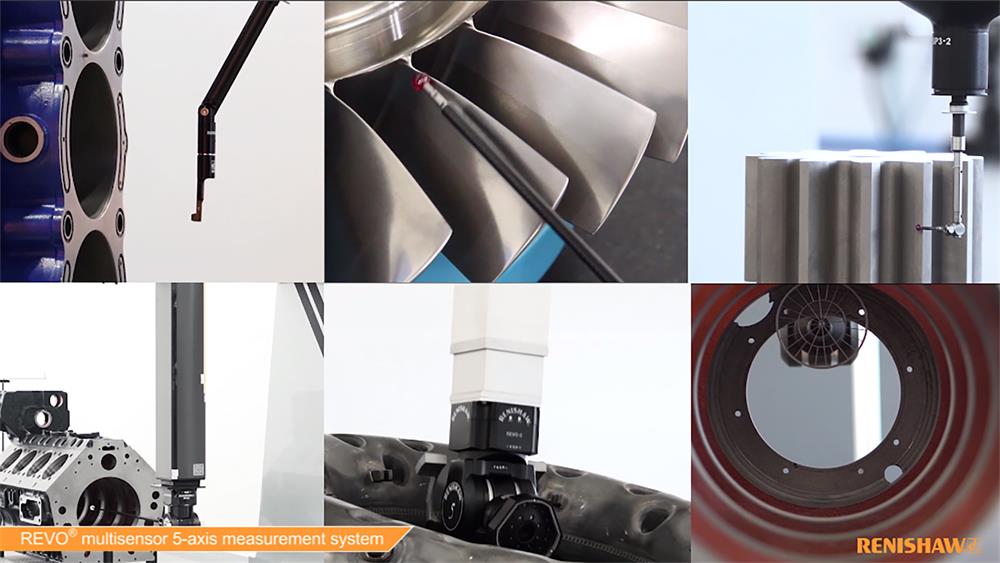

At EMO Hannover 2019, Renishaw, a world leading manufacturer of metrology systems, will be showing a new extended range of surface finish measurement probe modules for use with its REVO® 5-axis measurement system for CMMs, plus new functionality for MODUS metrology software – MODUS Planning suite.

REVO is a unique 5-axis multi-sensor system that synchronises the motion of the CMM and the measuring head's two axes to minimise the CMM's dynamic errors at ultra-high measuring speeds. The REVO system's five interchangeable sensors deliver automated dimensional and surface finish measurement on a single CMM with the speed, accuracy and flexibility of a 5-axis system.

Since the launch of the REVO SFP2 surface finish probe with expanded capability in 2017, Renishaw has released additional specialised modules, extending the surface finish measurement capability of the REVO system. The SFP2 system consists of a probe and a range of SFM modules which have been designed to suit the demands of specific parts and features encountered in a precision manufacturing environment. The probe and modules can be automatically interchanged with all other REVO contact and non-contact probe options, providing the flexibility to easily select the optimum tool to inspect a wide range of features.

The SFP2 range of modules comprises five specialised module series designed to deliver unique access capabilities for the most demanding industrial metrology applications. The module series, from A to E, have unique design features and optimal use: from the A-series designed to deliver high performance in engine block gasket face measurement and lateral scanning of crank shaft bearing journals, to the E-series featuring a two-part skid with a central stylus, ideal for short scans on small bores deep within the workpiece, as in the case of automatic transmission valve bodies.

The modules combine the 5-axis measurement and infinite positioning of the REVO system with the SFP2 probe's integral C-axis and take measuring capability to previously inaccessible surface measurement locations.

The new B-series of SFP2 modules is primarily designed for accessing features on complex and critical aerospace parts such as fan discs with undercuts and grooves, and where it may be critical to access all features from a single side to avoid unnecessary part handling. All B-series modules (SFM-B1 to B5) incorporate a 2 mm x 2 mm skid (compared to the standard 4 mm x 2 mm) which allows the 2-micron radius diamond stylus to be placed close to the edge of surfaces of interest. The five modules offer a choice of length and angle of attack, in addition to the flexibility provided by the manually adjustable module-to-holder knuckle joint, the motorised SFP2 probe C-axis, and the two axes of infinite positioning provided by the REVO head.

CMMs using the REVO system and SFP2 system are controlled by the UCC S5 controller, which gives the capability of 5-axis moves to automatically guide the stylus tip into features using compound curved paths generated from the part's CAD model. This is particularly useful when a clear path is obstructed or when a large part is close to the edge of the available measuring volume.

Renishaw's EMO Hannover 2019 stand in hall 6 will also feature metrology software demonstrations, including a new addition to MODUS™ metrology software: MODUS Planning suite.

The MODUS Planning suite is designed to provide CMM users with a set of automated shortcuts to frequent challenges in part programming, maximising the efficiency of their REVO CMM head with a set of easy-to-use specialised software applications. MODUS Planning suite allows users to plan complex geometry programs with minimal effort and improved efficiency using two new software tools: MODUS Patch and MODUS Curve.

MODUS Patch - until now, users had to define their own paths for surface sweeps and 2D curves using manual manipulation tools to avoid collisions. Now, the new MODUS Patch application delivers the most efficient measurement path with the REVO RSP2 sensor, quickly and easily, with automatic on-surface path planning.

MODUS Curve – this new application incorporates constrained CMM motion, which reduces CMM axis motion when measuring curves on a plane. Constraining the machine axis motion to a single plane improves accuracy and repeatability. MODUS Curve is particularly valuable for automotive manufacturing as many automotive parts require the measurement of curves for their validation.

From September, 15th – 21st, visitors will be able to see the SFP2 system and MODUS metrology software demonstrations on Renishaw's stand in hall 6 at EMO Hannover 2019.

For further information, visit www.renishaw.com/cmm.

Downloads

- News release: Enhanced access capability for the REVO 5-axis measurement system and new MODUS CMM metrology software functionality [66kB]

-

REVO-2 and SFP2 measuring crankshaft

[6.0MB]

REVO-2 and SFP2 measuring crankshaft

[6.0MB]

-

REVO-2 SFP2 measuring engine block

[5.1MB]

REVO-2 SFP2 measuring engine block

[5.1MB]

-

REVO measuring aerospace IBR

[4.0MB]

REVO measuring aerospace IBR

[4.0MB]

-

REVO scanning valve

[7.8MB]

REVO scanning valve

[7.8MB]

-

MODUS Planning Suite - Patch - Generating sweeps on CAD Edges

[192kB]

MODUS Planning Suite - Patch - Generating sweeps on CAD Edges

[192kB]

-

MODUS Planning Suite - Sketch on a plane simulation

[131kB]

MODUS Planning Suite - Sketch on a plane simulation

[131kB]

-

MODUS Planning Suite - Curve sketch

[626kB]

MODUS Planning Suite - Curve sketch

[626kB]

For further images, videos, company biographies or information on Renishaw and its products, visit our Media Hub.