EPflex case study

Background

Many examinations and surgical interventions in the human body are carried out in a minimally invasive way. Such methods are used in areas including ureterorenoscopy, ureter and kidney endoscopy, gastroenterology, interventional cardiology and vascular surgery. Stents and heart valves can be inserted into veins while kidney and bladder stones can be removed through the respective ducts. Treatments do require various small instruments. These are inserted into arteries, veins, ureters, bile ducts, and pancreatic ducts. Guide wires are an essential part of this.

When Bernhard Uihlein founded EPflex Feinwerktechnik GmbH in 1994, he concentrated on developing and producing such wires. Over the last 30 years, EPflex has significantly expanded its product range.

Today, EPflex produces guide wires, stone retrieval devices, snares, and other components for low-impact interventions. These are made of stainless steel and highly flexible, super-elastic nitinol, a nickel-titanium alloy with memory-effect properties. The company, which has around 400 employees, is one of the world's leading manufacturers of high-tech instruments and accessories for minimally invasive surgery.

Challenge

Reliable processes are crucial in single-part production. Marcel Steinke, Machining Team Leader, explains “With complex workpieces, such as forming tools and clamping devices, an incorrectly set tool can result in rework or damage to the component. This could ultimately slow the entire production process. As such, error-free machining is important, from design to the start of production and the assembly of our equipment and systems.”

To make sure that their process was reliable, EPflex needed to check the health of small, intricate tools quickly and accurately.

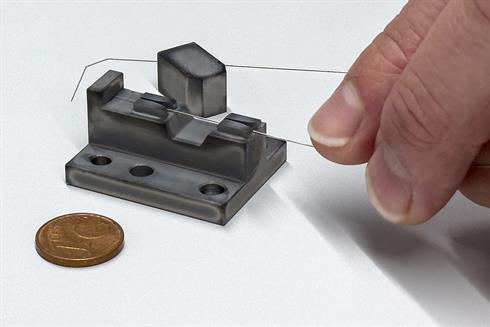

Udo Hönle, Head of Plant Engineering, says: “Before thin wires can be formed, the requisite tiny features must be applied to the forming tools and guide rails. This means milling narrow grooves of a few tenths of a millimetre and drilling holes with a diameter of 0.2–1 mm. The milling tools used sometimes have a diameter of just 0.03 mm.”

Previously length and diameter of the tools were measured away from the machine with pre-setters, and tool wear was visually assessed. This process is much slower, less accurate and repeatable, compared to on-machine measurement.

As a result, they explored non-contact tool measuring devices. These devices, installed in the work area of machining centres, use a laser beam to measure tools clamped in the spindle. This process checks for broken tools and measures tool length and diameter, preventing faulty machining.

Solution

EPflex identified the Renishaw NC4+ Blue laser tool setter as the best option. It boasts exceptional accuracy and repeatability, compared to competing red systems. Michael Seitz, Head of Key Account Management at Renishaw GmbH, explains: “NC4+ Blue can measure the smallest tools used at EPflex reliably and repeatably. What is often overlooked is that the short wavelength of the blue laser light also increases tool-to-tool accuracy.”

This system is ideal for manufacturers that demand reliable processes. Seitz adds: “Our non-contact tool measuring systems can be easily installed in the work areas of various machining centres. With sophisticated protective features, they can measure reliably and robustly in harsh environments.”

Instead of shutters, which require regular maintenance, the NC4+ Blue uses passive protection methods to protect the laser and electronics from coolant, chips, and dirt. Continuous high-speed air flow through the NC4 MicroHole™ aperture keeps debris away from the laser optics. If the air is switched off, the NC4 PassiveSeal™ mechanism inside the head activates, to prevent debris and coolant from entering the device.

EPflex also deploys Renishaw's OMP600 high-accuracy probe to locate the part before machining. Then, using Renishaw's intuitive Set and Inspect on-machine app, the experts can create probing and tool setting cycles all in one interface. This is essential for ensuring a quick and reliable process in single-part production.

The NC4+ Blue is the only laser tool setter in the market with a blue laser. A blue laser has a much shorter wavelength compared to a red laser, creating a smaller beam diameter. At the edges, the blue laser beams are deflected (diffracted) within much smaller tolerances. This allows the NC4+ Blue to measure small tools and intricate features precisely, delivering greater tool-to-tool accuracy than comparable red systems.

The NC4+ Blue laser tool setter helps surgeons gain more confidence in miniaturised instruments and implants for minimally invasive surgery, leading to their increased use. In future investments in machining centres, we will of course use the blue laser system again.

EPflex (Germany)

Results

EPflex has developed a quicker, more reliable production process by utilising the NC4+ Blue non-contact tool setter. By conducting automated, on-machine tool measurements, they have reduced measurement time from minutes to seconds and reduced the number of manual tasks performed by skilled operators.

Adopting the NC4+ Blue has revolutionised EPflex's ability to measure small tools accurately and repeatably. The blue laser creates a finer beam compared to a red laser, which is suitable for measuring tools just 0.03 mm in diameter. Automated, non-contact measurement minimises the risk of tool breakage or damage and reduces the chance of faulty machining.

After four years of using the NC4+ Blue tool setter on a Mazak VCN machining centre, the engineers at EPflex can confirm its advantages. Udo Hönle is convinced: “The NC4+ Blue laser tool setter helps surgeons gain more confidence in miniaturised instruments and implants for minimally invasive surgery, leading to their increased use. In future investments in machining centres, we will of course use the blue laser system again.”