Fully automated Raman imaging and microscopy

Renishaw's fully automated Raman spectrometers are perfect for routine use in multi-user laboratories. You can change measurement settings and run daily optimisation routines with just one click. Users can also save measurement templates to be consistent when analysing similar samples.

Scientists can control their Renishaw Raman system remotely and access their Raman data from anywhere in the world. Our support engineers can also diagnose any issues and optimise your Raman system over a network connection.

Raman configuration change with just one click

We design our Raman instruments for non-expert users. With just one click, you can swap between different instrument settings. You do not need to manually align any optics when changing between microscope viewing or Raman analysis modes. This includes microscope illumination modes (e.g. brightfield, darkfield or polarised), laser wavelengths, filters and gratings. This is because Renishaw's WiRE software remembers the position of each optical component and can swap it with just one click.

Confocal Raman microscopy with the EasyConfocal™ method

The inVia™ confocal Raman microscope uses the EasyConfocal™ method to achieve high spatial resolution. The EasyConfocal method is a proven way of producing 1D profiles, 2D images and 3D volumes at high spatial resolution. It gives you excellent confocal performance without a hard-to-align pinhole. With the EasyConfocal method, you have fully automated control of the confocal sampling volume of a Raman measurement. Choose between:

• Standard mode for most imaging and analysis experiments.

• High confocal mode for 3D volume imaging, or depth profiling of layered materials.

Confocal Raman microscopes restrict the sampling volume by placing an aperture at a suitable point before the detector. The aperture rejects out-of-focus and off-axis light from outside the sampling volume. The EasyConfocal method removes the need for a pinhole to achieve high spatial resolution. This method combines two apertures: one physical (the spectrograph entrance slit) and one defined in software (the height of the captured image on the CCD). This is an effective spatial filter for the scattered light, and we have demonstrated spatial resolution as good as that of a classical pinhole-based microscope.

This has significant advantages over a traditional pinhole. The EasyConfocal method maintains full confocal performance throughout the UV-visible range. There is no need to realign or refocus the pinholes. You can use an automated routine to optimise throughput with just a single click in the software.

Raman microscopes with auto-alignment and calibration

Renishaw's Raman systems have auto-alignment and daily calibration routines for reliable operation. You can run these fully automated routines within WiRE software. In addition, our advanced spectrographs use encoders to control the movement of optical components. As a result, our Raman instruments have very stable spectral calibration and sensitivity. You can trust Renishaw spectrometers to get accurate and repeatable spectra.

The inVia™ confocal Raman microscope has daily quick calibration routines. These use an internal silicon sample (Si) to ensure precise Raman shifts. In addition, the auto-alignment routines can optimise the spectrometer slit position and CCD detector area for excellent throughput.

The RA802 pharmaceutical analyser and the RA816 biological analyser have a fully automated performance qualification (PQ) procedure. This daily procedure consists of an auto-alignment routine and a spectral offset calibration on silicon.

Automatic Raman collection from multiple points

With WiRE software, you can acquire Raman data from multiple locations by queuing measurements. A series of measurements can be set up to run unattended overnight. This can maximise the use of your Raman instrument and improve lab productivity, which is critical for industrial quality control or contaminant analysis.

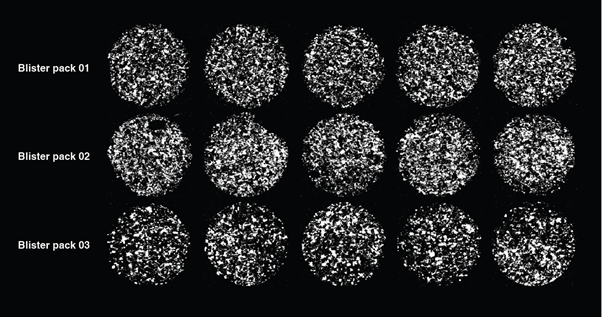

The inVia microscope, the RA802 analyser and the RA816 analyser can all use WiRE software's batch measurement function. Running a batch measurement will repeat the same Raman measurement at multiple locations as specified by a coordinate list. This can provide statistically significant data by sampling multiple pharmaceutical tablets or biological tissue sections using identical conditions. See our product note: Automated data collection with WiRE to find out how.

Raman imaging of fifteen pharmaceutical tablets using a fully automated procedure. This included batch measurements and LiveTrackTM focus-tracking technology. White regions indicate the location of the active pharmaceutical ingredient (API). The time required to load the sample and start the measurement was less than 2 minutes.

Remote diagnosis and support

Full automation enables our dedicated team of support engineers to diagnose any problems over a network connection. We can remotely optimise alignment and verify that your Renishaw Raman instruments are operating correctly.

Renishaw's team of support engineers are ready to service your fully automated Raman spectrometer remotely, as required.

Renishaw's team of support engineers are ready to service your fully automated Raman spectrometer remotely, as required.