Encoders for position and motion control

Renishaw offers a comprehensive range of non-contact encoders for position and motion control. Learn about our open and enclosed optical, inductive, magnetic and laser encoders.

Find your Renishaw motion control solution

Need an encoder for a position and motion control system? Discover how our different types of encoder products can meet your industrial automation needs. Renishaw's high-accuracy and high-quality encoders offer superior reliability, easy installation and are suitable for even the harshest environments.

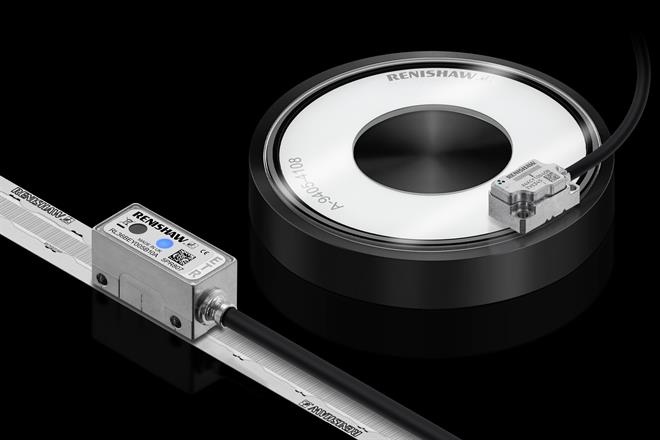

Open optical encoders provide robust and high-performance linear, rotary and partial arc position measurement. Our incremental encoders are suitable for motion systems where immediate and accurate relative position is required. Renishaw's absolute encoders offer functional immunity from power interruption.

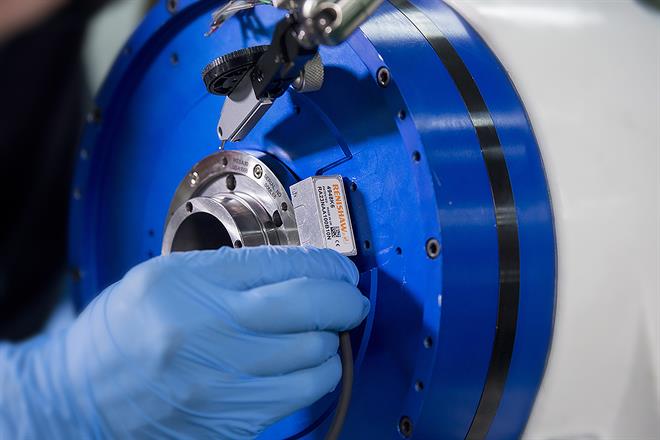

Enclosed optical encoders offer an exceptionally robust design, ideal for harsh industrial environments such as machine tools. Our proven absolute position measurement technology is robust and reliable. Non-contact design enhances repeatability and reduces wear. Superior sealing provides greater resistance to contamination by fluids and solid debris.

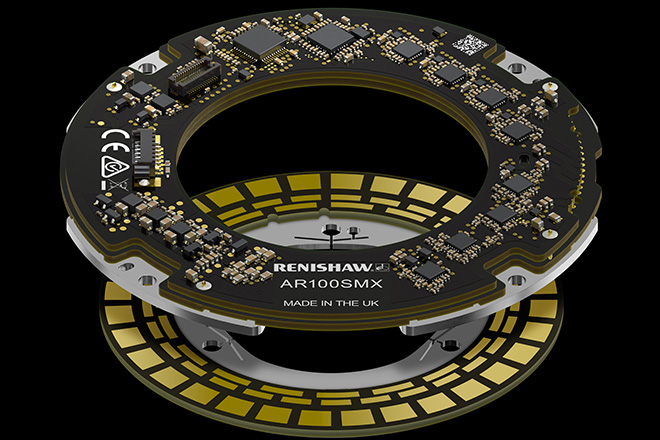

An absolute inductive encoder is a type of position sensor that uses electromagnetic induction to measure the position or motion of an axis. It provides accurate and robust position measurements in demanding operating environments.

Laser encoders provide linear position measurement with high resolution and low cyclic error. They combine the measurement performance of a displacement interferometer with the ease of use and installation of traditional tape or glass scale encoders.

Magnetic encoders provide highly reliable linear and rotary position measurement. Their robustness allows incremental and absolute position measurement operation in harsh environments. Non-contact design ensures no mechanical wear during operation.

Watch our introduction to Renishaw's range of encoders

Which areas of industrial automation use encoders?

We supply encoders to a wide range of industries and applications, including:

- electronics

- aerospace

- medical

- scientific research

- machine tools

- gimbals

- motion control

- semiconductor

- robotics

- flat panel display

- co-ordinate measuring machines (CMMs)

- medical devices

- renewable energy

- solar PV

- precision metrology

- unmanned aerial vehicles (UAVs)

- robots

Renishaw encoders feature a zero-wear non-contact design. We offer incremental and absolute scales in a variety of materials. Our readheads provide position signals with low electrical noise and high resistance to vibration.

Find out more in our introduction to encoder systems article.

The installation of the FORTiS enclosed encoder is very simple, which has greatly improved our productivity. Our latest grinding machines have been equipped with the FORTiS encoder and are now entering mass-production. We are very optimistic about the future development of grinding machines.

Mr Ranganatha, Director of Tool Grinding Technologies Inc.

How do we support you?

Renishaw will be there to provide service and support, no matter where you and your customers are. We are dedicated to ensuring that you have everything you need. Renishaw offices are located around the world. Our designers and technical experts in the UK are always available to provide application advice and installation support.

Our local teams provide:

- Sales and after sales

- Training and technical support

- Spare parts and repair services

Our encoders have CE approval and RoHS compliance. They are manufactured by Renishaw, following strict quality controls certified to ISO 9001:2015.

We understand that each encoder installation is different. Therefore, we offer customised readheads and scales to meet the specific needs of OEM customers. Common requirements for custom solutions include resolutions, connectors, scale and cable lengths and mechanical changes.

We have many years of experience in supporting integration challenges. Therefore, we strongly encourage direct engineering team discussions. This helps to ensure that custom solutions work properly the first time they are used in the application.

Warranty

Every Renishaw encoder product comes with a 2 year warranty and our industry-leading repair-by-exchange programme which immediately replaces a product from local inventory to ensure machinery downtime is kept to an absolute minimum.

How do our customers use our encoders?

See how others have trusted Renishaw encoders.

Our range of case studies showcases how our robust and high-performance encoders have solved precision measurement challenges.The applications are as varied as electronics, precision manufacturing, scientific research, aerospace, medical and healthcare.

Discover our global library of case studies, which includes a look at how Renishaw's FORTiS enclosed encoder has enhanced grinding precision and performance.

Discover our case studies

Trust Renishaw's expertise in encoders

As an industry-leading innovator, Renishaw re-invests each year between 14% and 18% of turnover into engineering, research and development. The results are ground-breaking new solutions for our customers. We are committed to creating unique technologies - pushing encoder performance to new levels.

We launched our first encoders in 1989. Since then, our metrology innovations and reputation for engineering excellence have established us as a leader in our markets.