Probing solutions for industrial automation

Achieve advanced robot automation with probes in your cell

The RCS P-series is a range of probes specifically designed to mount onto a robot arm or in a robot cell. For over 50 years, Renishaw has manufactured probes, providing industry leading levels of accuracy for part setting and inspection. Now this expertise is integrated into the industrial automation industry.

The RCS P-series range includes hard-wired, radio, and optical transmission probing solutions for industrial automation. As well as a tool setter for tool frame calibration. Ensuring the consistent 3D path accuracy of robots employed for intricate work including welding, additive manufacturing, machining, and dispensing.

Our probes are compatible with many of the major robot brands including ABB, Fanuc, KUKA, Yaskawa, and Staubli robots.

Automatically locate tool and part frames, and autonomously run recovery routines; eliminating costly and inefficient manual involvement.

Understand more about the RCS P-series probing solution

Learn more about how to enable advanced calibration in your robot cell.

Discover the benefits of RCS P-series for industrial automation

The RCS P-series is an industrial robot calibration and maintenance solution. It introduces calibrated probing to robot cells, enabling advanced datum functions. By understanding all components of a cell in six degrees of freedom (DOF) relative to each other, your robot can perform to its full potential.

Recover your cell effortlessly

Minimise downtime by automatically recovering after collisions.

Offline programming

Calibrate probes and align parts, even when your robot is offline.

Simplify steps to integrate

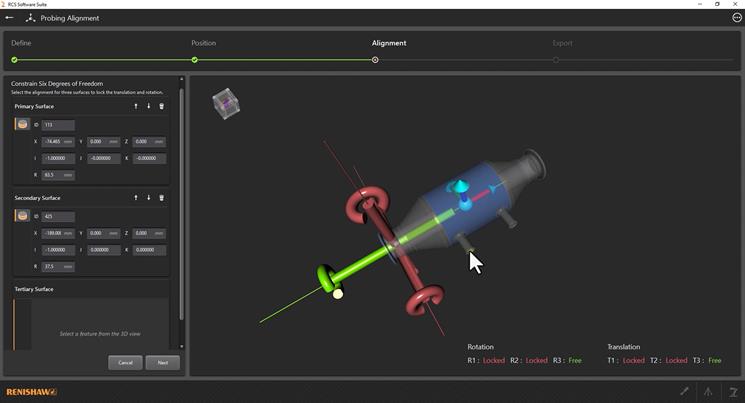

Intuitively set up a datum with the RCS Software Suite. Make probing accessible to all system integrators.

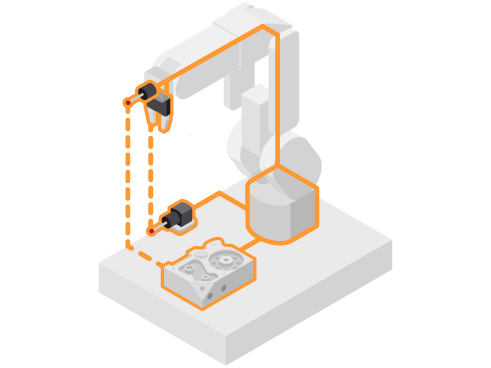

Closing the metrology loop with automation

Robot cells are designed to be operated with minimal human intervention. To truly run autonomously, a closed loop approach is achieved.

By introducing RCS P-series probes, all critical parts of the robot cell can be understood relative to each other. Linking the end-effector TCP, probe TCP, and part frame in 6 DOF and forming a metrology loop in the cell.

The supporting RCS Software Suite is used to create part datums by importing CAD models or nominal dimensions.

Our range of probes for robots

The RCS P-series offers a range of probing options for your specific robot cell requirements. You can choose hard-wired or wireless part setter options, both with or without a tool setter. You can also include an RCS P-series RPU - a controller which interfaces directly with the robot controller for probe calibration and metrology calculations.

Hard-wired probe

Select the most straightforward option for when a hard-wired part setting probe suits your cell.

Radio probe

Integrate probing within industrial robotics using a radio (wireless) part setting probe and receiver.

Optical probe

For when your cell requires a wireless part setting probe option, and line of sight to a receiver is achievable.

Tool setting probe

A tool setter is used to update tool frames, including robot-mounted spindle tools.

Upgrade your core licence to include the advanced probing option

Advanced probing allows you to create complex alignments from CAD files and nominal information. You can also evaluate feature best fits and relationships.

Enable machining on your robot with RCS spindle calibration

Automatically calibrate spindles using a Renishaw tool setter and an RCS spindle calibration disc stylus. Achieve 5 DOF calibration with several quick orientations.

The RCS probing server

Integrate RCS P-series into your robotic operations to achieve a more resilient, accurate, and efficient automation system. Adapt to changes and recover from disruptions, with minimal manual intervention.

To communicate with robots, RCS P-series features the RCS probing server application (Server). The Server stores and analyses data collected by probes. We offer a dedicated probing controller, the RCS RPU, to run the RCS probing server. Or, you can install it on an existing device in your cell set-up.

To give commands to the Server and your robot, we have developed macro instructions. These enable autonomous execution of calibration routines, providing 6 DOF control.

Real time monitoring enables immediate detection and correction of deviations, resulting in consistent quality from your robot.

After collisions or maintenance activities, automatic recovery means no need for manual reprogramming.

RCS P-series FAQs

What is included in an RCS P-series kit?

Each RCS P-series solution will look different for your specific robot application. You can build your kit with everything you need to meet these requirements. But, all RCS P-series must include at least:

- A part or tool setting probe (plus separate probe interface if applicable)

- RCS datum ball kit to calibrate your probe

- Styli for your chosen probe(s)

- A device on which to run the RCS probing server application, such as an RCS RPU

- Core probing licence USB dongle key

Which brands of robots do you support?

The RCS P-series currently supports six axis industrial robots from ABB, Fanuc, KUKA, Staubli, Mitsubishi and Yaskawa. SCARA robots which meet specification requirements are also supported.

Our family of robots is constantly growing, so do contact your Renishaw representative to discuss specific requirements.

Do I need to reprogram following a collision?

No, RCS P-series provides a solution to handle the correction and recovery of a cell seamlessly. This saves a large amount of time and effort. There is no need to re-teach the robot program following any collision, maintenance or movement of the robot.

Are the probes and RCS RPU covered by a warranty?

Yes, RCS probes and RCS RPUs are covered by a one year warranty.

How much does RCS P-series cost?

The cost of each RCS P-series solution differs. Contact your local Renishaw representative to discuss costs or fill out our contact form.

Support for robot calibration and maintenance products

Learn how to use industrial robot calibration and maintenance products with downloadable guides. Watch video tutorials on installing products and using our accompanying software package.

Downloads

-

Brochure: Advancing robotic automation - RCS P-series

[12.1MB]

Brochure: Advancing robotic automation - RCS P-series

[12.1MB]

-

Brochure: Simplifying robotic automation with RCS product series

[9.2MB]

Brochure: Simplifying robotic automation with RCS product series

[9.2MB]

-

Flyer: RCS PK1 hard-wired robot probe flyer

[1.1MB]

Flyer: RCS PK1 hard-wired robot probe flyer

[1.1MB]

-

Flyer: RCS TS1 hard-wired robot tool setter

[1.3MB]

Flyer: RCS TS1 hard-wired robot tool setter

[1.3MB]

-

Flyer: RCS R-PK1 radio robot probe flyer

[1.6MB]

Flyer: RCS R-PK1 radio robot probe flyer

[1.6MB]

-

Flyer: RCS O-PK1 optical robot probe

[994kB]

Flyer: RCS O-PK1 optical robot probe

[994kB]

-

Flyer: RCS spindle calibration kit

[1.3MB]

Flyer: RCS spindle calibration kit

[1.3MB]