Renishaw goes big on nanofiber

To help with ongoing personal protective equipment (PPE) shortages, Ontario-based nanofiber manufacturer, BIG-nano, has collaborated with Renishaw to create a local supply chain for protective masks using additive manufacturing (AM).

BIG-nano developed a fine liquid blowing technique for the production of nanofiber, allowing it to more easily scale production at affordable costs. Renishaw used one of its RenAM 500Q system located in Canada to build a novel titanium nozzle for the liquid blowing process, capable of producing N99 quality fabric, while reducing maintenance costs and downtime.

3D printed nozzle

Background

In 2018, BIG-nano developed a novel gas-assisted jetting process to manufacture nanofibers — polymer fibres with diameters in the nanometre range. Its technique streams high-velocity gas through a needle, while a polymer liquid solution is simultaneously accelerated to the tip of the same nozzle. The two streams interact, bringing the polymer from molten to fibre state and producing a poly (vinyl alcohol) nonwoven fibre mat.

Nanofibers are steadily gaining popularity in drug delivery systems, medical implant devices, water and air filtration, and protective clothing applications. After COVID-19 caused a shortage in PPE for healthcare workers, BIG-nano saw an opportunity to contribute.

N95 and N99 masks are produced using a fine mesh of polymer fibres to filter particles and are regarded as the gold standard for healthcare workers and other medical first responders. To meet the standard, these face coverings must ensure a 95 and 99 per cent filtering of airborne particles, protecting users from COVID-19. Nanofibers are particularly effective at achieving a high percentage of particle filtration.

“The Coronavirus pandemic demonstrated to nations worldwide that some products like PPE should be manufactured locally for the national interest,” explained John Rawlins, co-founder of BIG-nano. “Supply chains around the world broke down in a way that no one anticipated. The call by the Canadian Government to work on PPE locally in a way that is secure for our communities interested us. It was something immediate and good that we could do, so we stepped up to that challenge.”

Challenge

The initial challenges facing BIG-nano were to make its technology practical to implement in large scale manufacturing, while maintaining N95 nanofiber quality. BIG-nano's first design for its equipment was monolithic, meaning that a single component failing would require expensive maintenance and downtime on the entire machine. In particular, the nozzle must sustain substantial pressure and temperature changes, which led the team to prioritise its redesign.

"The nozzle consists of a compressor system, which heats the air, and an extruder, which melts the polymer," explained John Rawlins. "That polymer is then brought into the extruder to meet the heated gas. The nozzle does the work of processing the polymer from molten to fibre state, it really is the heart of the whole system."

"Our original design was highly efficient, which allowed us to make nanofiber at microfiber prices. The drawback was that it was arranged in an unconventional way," continued Rawlins. "Our design was also very complex, which meant that we had to collaborate with an engineering partner that had experience with thermal dynamics and pressurised and heated fluids."

When approaching Renishaw, BIG-nano emphasised the importance of scalability, easy maintenance and consistent quality. In addition, the urgent factors motivating the manufacturing of N95 masks also meant that the project had to be completed as quickly as possible.

Renishaw brought valuable additive manufacturing expertise we didn't have in-house, giving us the ability to produce prototypes for a new nozzle design quickly, despite their complexity.

BIG-nano (Canada)

Solution

“We realised machining the nozzle for our jetting process would mean we couldn't complete the project in time, so we looked to additive manufacturing for a solution,” shared Rawlins. “Renishaw brought valuable additive manufacturing expertise we didn't have in-house, giving us the ability to produce prototypes for a new nozzle design quickly, despite their complexity.”

"BIG-nano presented us with a project that was a challenging but clearly valuable application of AM," explained Carl Hamann, Additive Applications Specialist at Renishaw. "We were under time pressure to produce new prototypes to improve upon a design with complex internal geometries. We chose to use a RenAM 500Q machine, as the multi-laser system would quadruple build speed."

The RenAM 500Q features four high-power 500 W lasers, which can address the entire build plate. The machine also comes with automated powder and waste handling systems that enable consistent process quality. Renishaw's system fits comfortably with BIG-nano's requirements, allowing engineers to both minimise build time and ensure consistent part quality.

"We couldn't take the original design for the machine and build it using AM directly. It was too large and consisted of numerous large blocks of metal that could more easily be machined," continued Hamann. "Instead, we selected components that would bring the most benefit and redesigned them for the AM process. This led us to change the design of the machine to a modular one that can be disassembled and refitted with AM parts indefinitely."

A modular design brings significant advantages for time-sensitive manufacturing, as if the nozzle were to fail or wear through time, a substitute could be built quickly with AM and installed. This could reduce both maintenance costs and overall downtime. In addition, N95 is a difficult standard to achieve, so for the nanofiber to consistently achieve that quality the nozzle must be resistant to wear. This led Renishaw to produce the part in titanium to further minimise maintenance.

RenAM 500Q multi-laser AM system

RenAM 500Q multi-laser AM system

"In order to go rapidly from one iteration to the next, we tested components with aluminium prototypes. This allowed us to design, produce, test and improve three iterations in just three weeks," explained Hamann. "This introduced some new challenges as aluminium is more susceptible to thermal expansion than titanium. Cycling of cold and hot temperatures took its toll on the tool, but fortunately rapid prototyping allowed us to find better ways of cycling the polymer and gas."

"I was particularly impressed with the turnaround for each iteration of the nozzle. In three weeks, we achieved what could otherwise have taken up to nine months," shared Rawlins. "Every process has instabilities; the central aspect of our design is to understand how they would affect the end-product and minimise any factors that could prevent us from reaching N95 quality. For us to achieve this more than nine times faster than expected is unprecedented."

Renishaw's REVO® 5-axis system is used for the fast and accurate inspection of the new nozzle design

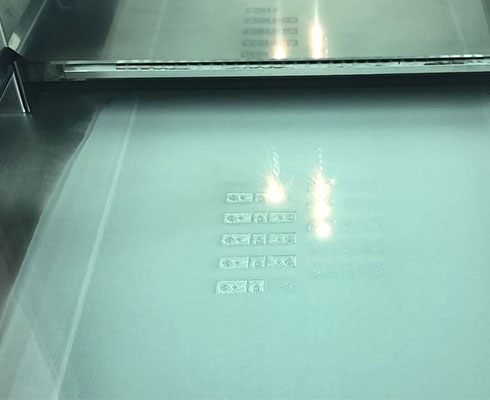

The nozzle being printed on a RenAM 500Q system

Results

Renishaw and BIG-nano are still collaborating to perfect the system. The team's goal is to make the nozzle larger to increase nanofiber throughput and allow larger volumes of mask production.

“While we initially aimed for N95 quality, our improved AM design can produce N99 nanofiber,” explained Rawlins. “This is a very welcome surprise since we initially were concerned with maintaining N95 quality in a scalable way. It goes to show how effective AM prototyping can be.”

“We are now looking past PPE and considering new applications where nanofiber could benefit society. Coronavirus is going to pose challenges in indoor spaces, as it appears people are most likely to catch it in confined spaces. For heating, ventilation, and air conditioning (HVAC) equipment to protect workers in office spaces effectively they must be substantially upgraded. While doing so with hardware improvements could work, we think that we could achieve comparable results by retrofitting nanofiber in current filtration systems. This could save users substantial hardware costs.” concluded Rawlins.

John Rawlins, co-founder of BIG-nano inspecting the Poly (vinyl alcohol) nonwoven fibre mat

John Rawlins, co-founder of BIG-nano inspecting the Poly (vinyl alcohol) nonwoven fibre mat